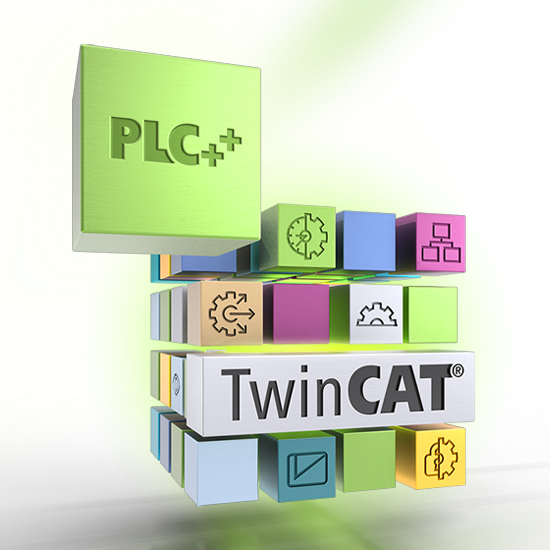

Next generation PLC technology

TwinCAT PLC++: Engineering and runtime with a significant leap in performance

Headquarters Canada

Beckhoff Automation Ltd.

TwinCAT PLC++: Engineering and runtime with a significant leap in performance

Discover our product news and find out how they can boost the performance of your application. The mainareas that the product range covers are industrial PCs, I/O and fieldbus components, drive technology, automation software, control cabinet-free automation, and hardware for machine vision.

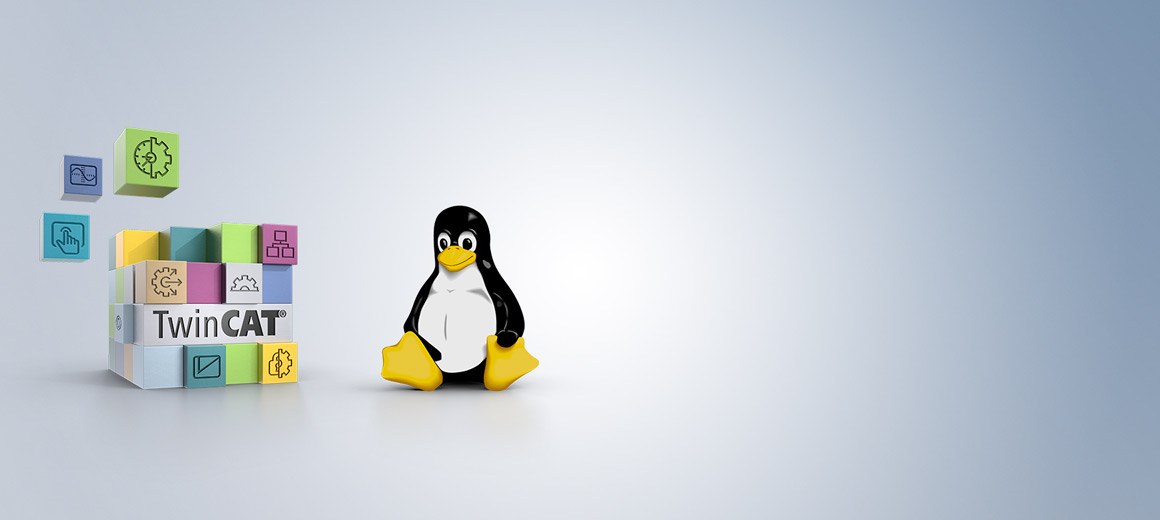

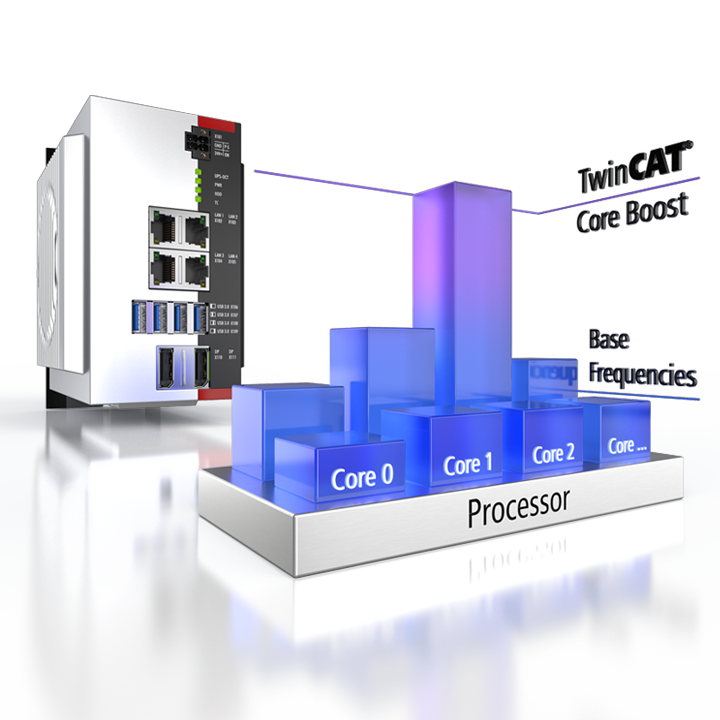

Enormous leap in performance thanks to processor cores in turbo mode - TwinCAT Core Boost for greater computing performance in real time

Four new EtherCAT Terminals for multi-channel measuring bridge detection with integrated power supply.

Multi-functional and powerful with 16 bits and up to 8 channels for all standard signals between ±10 V and ±20 mA.

Economy drive system for low- to mid-range performance requirements

With TwinCAT PLC++, Beckhoff is delivering a new generation of PLC technology that accelerates both engineering and runtime.

Linux® distribution from Beckhoff lays foundation for new type of runtime

Beckhoff presents the latest generation of motion software solutions in TwinCAT MC3.

Our MX-System combines all technological innovations in automation technology in an IP67-capable modular system.

Enormous leap in performance thanks to processor cores in turbo mode - TwinCAT Core Boost for greater computing performance in real time

Linux® distribution from Beckhoff lays foundation for new type of runtime

The C6043 extends the series of ultra-compact industrial PCs to include a high-performance device with a built-in slot for powerful graphics cards. With the latest Intel® Core™ processors and highly parallelizing NVIDIA® graphics processors, the PC becomes the perfect central control unit for ultra-sophisticated applications. These include applications with high demands on 3D graphics or deeply integrated Vision and AI program blocks with minimal cycle times. The Beckhoff TwinCAT 3 control software is capable of mapping this as a fully integrated solution – without any additional software or interfaces. With the additional freely assignable PCIe compact module slot, the C6043 can be flexibly expanded with supplementary functions.

The C6670-0020 industrial server is equipped with two Intel® Xeon® scalable processors from the 5th generation with up to 32 cores per CPU and a memory of 128 to 1,024 GB DDR5 RAM. This makes it ideal for machine controls, for example with the XPlanar planar motor system. The C6670-0020 can be ordered with M.2 NVMe SSDs up to 640 GB and up to two hard disks with 1, 2, or 4 TB. It also features five free PCIe slots for EtherCAT or Ethernet fieldbus cards or similar.

The built-in panel PC is equipped with Intel Atom® x6 series processors.

The panel PC is equipped with Intel Atom® x6 series processors.

The panel PC with 100 x 100 mounting arm adaption is equipped with Intel Atom® x6 series processors.

The CP6700-1400 and CP6706-1400 built-in Panel PCs with stainless steel finish are designed for installation in the front of a control cabinet or control housing and, with their highly integrated 3½-inch motherboard, they represent a powerful platform for use in machine construction and plant engineering, for example with the TwinCAT automation software running on Windows 10 IoT Enterprise. They are available with two different touch screen displays with a 7 or 10.1-inch screen size.

The CP6900-1400 and CP6906-1400 economy Control Panels in stainless steel finish supplement the Industrial PC entry level class by two built-in Control Panels with DVI/USB Extended interface. The Panels are designed for installation in the front of a control cabinet and have a 7-inch or 10.1-inch touch screen display. In combination with the compact Embedded PCs from the CX series or the Industrial PCs of the type C6xxx, a low-cost PC/panel system results. A 24 V power supply unit is included with the Control Panel. The integrated DVI/USB Extended technology enables the Panel to be positioned up to 50 m from the PC.

With Microsoft Windows 11 IoT Enterprise 2024 LTSC (version 24H2), Beckhoff introduces the successor to Microsoft Windows 10 IoT Enterprise 2021 LTSC (version 21H2). Windows 11 supports multi-touch operating concepts and makes the tile design come to life. Pricing is oriented to CPU classes, allowing processors in the mid-performance range to be offered at considerably lower prices. The operating system is only available as a 64-bit version.

The CX7291 Embedded PC has an Arm® Cortex®-A9 single-core processor with 720 MHz. In the basic configuration, the CX7291 has a slot for a microSD card and an Ethernet interface. As a special feature, the CX7000 series has eight integrated multi-functional inputs as well as four integrated multi-functional outputs.

The CX7293 Embedded PC has an Arm® Cortex®-A9 single-core processor with 720 MHz. In the basic configuration, the CX7293 has a slot for a microSD card and an Ethernet interface. As a special feature, the CX7000 series has eight integrated multi-functional inputs as well as four integrated multi-functional outputs.

The EL1409 digital input terminal acquires the binary 24 V control signals from the process level and transmits them, in an electrically isolated form, to the higher-level automation unit. The EtherCAT Terminal has 16 channels, whose signal states are indicated by LEDs. The power contacts are connected through. With the EL1409, the reference ground for all inputs is the 0 V power contact.

The EL1417 digital input terminal acquires the binary 24 V control signals from the process level and transmits them, in an electrically isolated form, to the higher-level automation unit. The EtherCAT Terminal has 32 channels, whose signal states are indicated by LEDs. The power contacts are connected through. With the EL1417, the reference ground for all inputs is the 0 V power contact.

The EL1429 digital input terminal acquires the binary 24 V control signals from the process level and transmits them, in an electrically isolated form, to the higher-level automation unit. The EtherCAT Terminal has 16 channels, whose signal states are indicated by LEDs.

The EL1489 digital input terminal acquires the binary 24 V control signals from the process level and transmits them, in an electrically isolated form, to the higher-level automation unit. The EtherCAT Terminal has 16 channels, whose signal states are indicated by LEDs. The power contacts are connected through. With the EL1489, the reference ground for all inputs is the 24 V power contact.

The EL2407 digital output terminal connects the binary 24 V DC control signals from the automation device on to the actuators at the process level with electrical isolation. The EtherCAT Terminal has 32 channels, whose signal states are indicated by LEDs. The power contacts are connected through. The connection technology is particularly suitable for single-ended inputs. All components have to use the same reference point as the EL2407. In the EL2407 the outputs are supplied via the 24 V DC power contact.

The EL2409 digital output terminal connects the binary 24 V DC control signals from the automation device on to the actuators at the process level with electrical isolation. The EtherCAT Terminal has 16 channels, whose signal states are indicated by LEDs. The power contacts are connected through. The connection technology is particularly suitable for single-ended inputs. All components have to use the same reference point as the EL2409. In the EL2409 the outputs are supplied via the 24 V DC power contact.

The EL2489 digital output terminal connects the binary 24 V DC control signals from the automation device on to the actuators at the process level with electrical isolation. The EtherCAT Terminal has 16 channels, whose signal states are indicated by LEDs. The connection technology is particularly suitable for single-ended inputs. All components have to use the same reference point as the EL2489. The power contacts are connected through. In the EL2489 the outputs are supplied via the 0 V DC power contact.

The EL3008-0003 is designed for measuring stacked voltages up to 1000 V CAT II, such as those found in accumulators and fuel cells. The negative pole of one cell is also the positive pole of the next. In combination with the high galvanic isolation to the E-bus, these terminals can be used to record large cell stacks with minimal wiring. This allows cell behavior to be monitored during normal operation and facilitates rapid responses in case of malfunctions.

The EL3072, EL3074, and EL3078 analog input terminals record 10 V/20 mA standard signals with 16-bit resolution and up to 2000 measured values per second. Each channel can be parameterized individually via the controller/TwinCAT; signals in the range of -10…+10 V, 0…+10 V, -20…+20 mA, 0…+20 mA, and 4…+20 mA can be processed by each channel. In terms of electrics, the voltage and current signals must be connected to different terminal points. The voltage and current inputs are single-ended, which means that one connection point of each channel is already connected in the terminal to +24 V or GND and no longer needs to be wired separately. With a technical measuring range of ±107% of the nominal range, the terminals also support commissioning with sensor values in the limit range and the evaluation according to NAMUR NE43.

The EL3184 analog input terminal for HART-capable field devices supplies measuring transducers located in the field and transmits their analog measuring signals to the automation device under electrical isolation. With a technical measuring range of 107% of the nominal range, the terminal also supports commissioning with sensor values in the limit range and the evaluation according to NAMUR NE43.

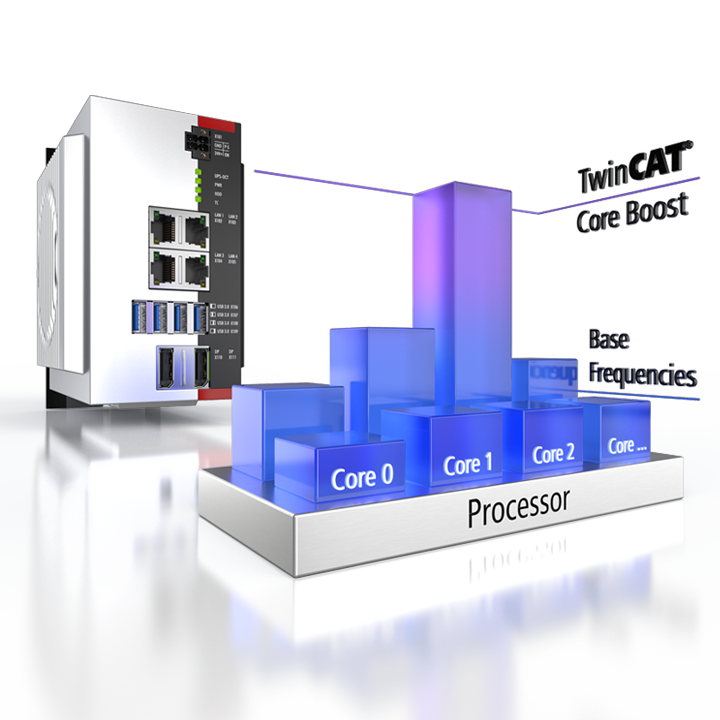

The EL3361 analog input terminal enables the direct connection of a resistor bridge (strain gauge) or a load cell using a 4-wire or 6-wire connection technique. It processes the ratio of the bridge voltage UD to the supply voltage UREF and outputs the final load value as a process value based on the terminal settings. This enables precise recording of weights, torques, and vibrations with a sampling rate of 10,000 samples per second.

The EL3361-0100 analog input terminal enables the direct connection of a resistor bridge (strain gauge) or a load cell using a 4-wire or 6-wire connection technique. It processes the ratio of the bridge voltage UD to the supply voltage UREF and outputs the final load value as a process value based on the terminal settings. This enables precise recording of weights, torques, and vibrations with a sampling rate of 10,000 samples per second. The integrated bridge supply is generated from the 24 V of the power contacts.

The EL3362 analog input terminal enables the direct connection of resistor bridges (strain gauges) or load cells using the 4-wire or 6-wire connection technique. It processes the ratio of the bridge voltage UD to the supply voltage UREF and outputs the final load value as a process value based on the terminal settings. This enables precise recording of weights, torques, and vibrations with a sampling rate of 10,000 samples per second.

The EL3362-0100 analog input terminal enables the direct connection of resistance bridges (strain gauges) or load cells using the 4-wire or 6-wire terminating system. It processes the ratio of the bridge voltage UD to the supply voltage UREF and outputs the final load value as a process value based on the terminal settings. This enables precise recording of weights, torques, and vibrations with a sampling rate of 10,000 samples per second. The integrated bridge supply is generated from the 24 V of the power contacts.

The EL3446-0011 EtherCAT Terminal enables measurement of all relevant electrical data in the supply grid and performs simple pre-evaluations. Since the EL3446-0011 itself has no voltage inputs, the measured voltage values are transmitted via EtherCAT from an EL3443 to be installed once per network. The current in the connectable phases – of which there are up to six – is fed in via simple current transformers. All measured currents and voltages are available as RMS values. In the EL3446-0011, the active power and the energy consumption for each phase are calculated. RMS values are available for voltage U and current I as well as active power P, apparent power S, reactive power Q, frequency f, phase shift angle cos φ, and harmonics. The EL3446-0011 offers options for comprehensive network analysis and energy management.

The EL4072, EL4074, and EL4078 analog output terminals output 10 V/20 mA standard signals with 16-bit resolution and up to 2000 values per second. Each channel can be parameterized individually via the controller/TwinCAT. All known standard signals in the range of ±10 V and ±20 mA can be output per channel – for example, 4…20 mA. The current outputs can also drive high burden resistors and report an overload or wire break or, in the case of a voltage output, a short circuit. The voltage and current outputs are designed as single-ended, which means that one connection point of each channel is already connected in the terminal to +24 V or GND and no longer needs to be wired separately. The EL4072 and EL4074 have 24 V/0 V contacts for the supply of the actuators. With a technical output range of ±107% of the nominal range, the channels can even transport unconventional setpoints, such as for error reporting purposes.

The EL4072, EL4074, and EL4078 analog output terminals output 10 V/20 mA standard signals with 16-bit resolution and up to 2000 values per second. Each channel can be parameterized individually via the controller/TwinCAT. All known standard signals in the range of ±10 V and ±20 mA can be output per channel – for example, 4…20 mA. The current outputs can also drive high burden resistors and report an overload or wire break or, in the case of a voltage output, a short circuit. The voltage and current outputs are designed as single-ended, which means that one connection point of each channel is already connected in the terminal to +24 V or GND and no longer needs to be wired separately. The EL4072 and EL4074 have 24 V/0 V contacts for the supply of the actuators. With a technical output range of ±107% of the nominal range, the channels can even transport unconventional setpoints, such as for error reporting purposes.

The EL4072, EL4074, and EL4078 analog output terminals output 10 V/20 mA standard signals with 16-bit resolution and up to 2000 values per second. Each channel can be parameterized individually via the controller/TwinCAT. All known standard signals in the range of ±10 V and ±20 mA can be output per channel – for example, 4…20 mA. The current outputs can also drive high burden resistors and report an overload or wire break or, in the case of a voltage output, a short circuit. The voltage and current outputs are designed as single-ended, which means that one connection point of each channel is already connected in the terminal to +24 V or GND and no longer needs to be wired separately. The EL4072 and EL4074 have 24 V/0 V contacts for the supply of the actuators. With a technical output range of ±107% of the nominal range, the channels can even transport unconventional setpoints, such as for error reporting purposes.

The EL4172 and EL4174 analog output terminals output 10 V/20 mA standard signals with 16-bit resolution and up to 10,000 values per second – even with distributed clocks if necessary. Each channel can be parameterized individually using the control/TwinCAT and supports all common standard signals in the ±10 V and ±20 mA range, such as 4...20 mA. The current outputs can drive high load resistances and are equipped with 24 V/0 V contacts to supply actuators. With an extended output range of ±107 %, unconventional setpoints can also be output – for error reporting purposes, as an example.

The EL4172 and EL4174 analog output terminals output 10 V/20 mA standard signals with 16-bit resolution and up to 10,000 values per second – even with distributed clocks if necessary. Each channel can be parameterized individually using the control/TwinCAT and supports all common standard signals in the ±10 V and ±20 mA range, such as 4...20 mA. The current outputs can drive high load resistances and are equipped with 24 V/0 V contacts to supply actuators. With an extended output range of ±107 %, unconventional setpoints can also be output – for error reporting purposes, as an example.

The EL6184 offers four interfaces for integrating HART-capable field devices. The EtherCAT Terminal serves as a secondary master and can be seamlessly integrated into existing connections. Maintenance and diagnostic data, for example, can be retrieved from field devices, as is the case in the context of NAMUR Open Architecture (NOA).

The ELM3002-0235 EtherCAT Terminal of the basic series is designed for high-voltage measurement on batteries and generators and supports the measuring ranges ±60/360/600 and 1200 V. The measuring range is selected in the CoE, as are the other setting options such as the filter parameters. Irrespective of the signal configuration, all ELM modules have the same technological properties. The ELM3002-0235 with oversampling offers a maximum sampling rate of 50,000 samples per second. The terminal is equipped with 4 mm lab jacks.

The ELM3002-0305 EtherCAT Terminal in the basic series is designed for low-voltage measurement in high-voltage systems (AC or DC), especially current measurement via shunt or single-cell measurement. It has an adjustable measuring range of ±60 mV to ±5 V per channel and electrical isolation between the channels. The measuring range is selected in the CoE, as are the other setting options such as the filter parameters. Regardless of the signal configuration, all ELM modules have the same technological properties, and the ELM3002-0305 with oversampling offers a maximum sampling rate of 50,000 samples per second and channel. The terminal is equipped with 4 mm laboratory sockets.

The ELM3002-0405 EtherCAT Terminal combines the high-voltage measurement of the ELM3002-0205 and the low-voltage measurement of the ELM3002-0305 in a 2-channel terminal. This means that an EtherCAT Terminal can simultaneously measure the total voltage of a cell stack or generator, as well as its current via a shunt. The synchronous coupling of several terminals – for the purpose of measuring a 3-phase system, for example – is possible using distributed clocks.

The ELM3102-0120 EtherCAT Terminal in the basic series is a reduced version of the ELM3702-0101 intended for voltage and current measurement. It offers measuring ranges from +60 V to -20 mV and ±20 mA at a rapid sampling rate of 20 kSps per channel. The electrical isolation between channels allows it to detect signals that are at different or fluctuating potentials with high accuracy in complex environments.

The 4- and 8-channel EtherCAT Terminals from the ELM334x economy series are designed for temperature measurement with thermocouples. All common thermocouple types are covered and, with a sampling rate of 1 ksps per channel, fast processes are also easy to record. The resolution is adjustable to 0.001°C. The channel properties can be adjusted individually for each channel via CoE. An exceptionally high measuring accuracy is achieved through the precise measurement of the internal cold junction.

The 4- and 8-channel EtherCAT Terminals from the ELM334x economy series are designed for temperature measurement with thermocouples. All common thermocouple types are covered and, with a sampling rate of 1 ksps per channel, fast processes are also easy to record. The resolution is adjustable to 0.001°C. The channel properties can be adjusted individually for each channel via CoE. An exceptionally high measuring accuracy is achieved through the precise measurement of the internal cold junction.

The 4- and 8-channel EtherCAT Terminals from the ELM334x economy series are designed for temperature measurement with thermocouples. All common thermocouple types are covered and, with a sampling rate of 1 ksps per channel, fast processes are also easy to record. The resolution is adjustable to 0.001°C. The channel properties can be adjusted individually for each channel via CoE. An exceptionally high measuring accuracy is achieved through the precise measurement of the internal cold junction.

The 4- and 8-channel EtherCAT Terminals from the ELM334x economy series are designed for temperature measurement with thermocouples. All common thermocouple types are covered and, with a sampling rate of 1 ksps per channel, fast processes are also easy to record. The resolution is adjustable to 0.001°C. The channel properties can be adjusted individually for each channel via CoE. An exceptionally high measuring accuracy is achieved through the precise measurement of the internal cold junction.

The EP1258-0002 EtherCAT Box with digital inputs acquires binary control signals from the process level and transmits them to the controller under electrical isolation. Compared to the EP1258-0002, the EP1258-0502 offers higher performance thanks to the XFC multi-timestamping function. Timestamp technology allows signals to be precisely retraced over time. Whereas the EP1258-0002 can accept one edge change with timestamp per bus cycle, the EP1258-0502 offers the possibility to register up to 32 events with timestamps. The EP1258-0502 is synchronized with other EtherCAT devices through the distributed clocks system, so that events in the whole system can be measured with a uniform timebase. The signal connection is established via screw-type M12 connectors. Two channels are available per M12 socket.

The EP1816-0703 EtherCAT Box with digital inputs acquires binary control signals from the process level and transfers them electrically isolated to the controller. The signal state is indicated by means of LEDs. The signal connection is established via spring-loaded connectors, optionally available in 1- and 3-pin versions. Thanks to the compact plug level, the EP1816-0703 can transfer 16 signals from the field via EtherCAT in a very small space.

The EP2339-0703 EtherCAT Box has 16 digital channels, which can each be operated as an input or output. It is not necessary to configure whether a channel is to be used as an input or output; the input circuit is internally permanently connected to the output driver so that a set output is automatically displayed in the input process image.

The EP2534-0002 EtherCAT Box regulates the output current by pulse width control of the peripheral voltage on four channels. The current values ranging from 0 to a maximum output current of 2 A are specified by the automation device through a 16-bit value. The sum current of all outputs is limited to 4 A. The output stages are protected against overload. The signal state of the channels is indicated by LEDs. The signal connection is established via screw-type M12 connectors. One channel is available per M12 socket.

The EP3048-0002 EtherCAT Box has 8 channels and processes 20 mA standard signals with 16-bit resolution and up to 2000 measured values per second. Each channel can be parameterized individually via the controller/TwinCAT; signals in the range of -20…+20 mA , 0…+20 mA and 4…+20 mA can be processed by each channel. The current inputs are designed as single-ended. With a technical measuring range of ±107 % of the nominal range, the module also supports commissioning with sensor values in the limit range and evaluation in accordance with NAMUR NE43. Two channels are connected via an M12 socket.

The EP3744-2041 EtherCAT Box, with six digital inputs, two digital outputs, and four pressure inputs, acquires these signals and transmits them to the controller under electrical isolation. The signal status is indicated by LEDs, while the signal interface for the digital signals utilizes 4-pin M8 screw type connectors.

The EP3744-3041 EtherCAT Box, with six digital inputs, two digital outputs, and four pressure inputs, acquires these signals and transmits them to the controller under electrical isolation. The signal status is indicated by LEDs, while the signal interface for the digital signals utilizes 4-pin M8 screw type connectors.

The EP3754-0002 EtherCAT Box has four analog multifunctional inputs, which can be extensively parameterized on an individual basis:

The EP3754-0702 EtherCAT Box has four analog multi-functional inputs, which can be extensively parameterized on an individual basis:

The EP6222-0002 IO-Link module enables connection of up to two IO-Link devices, e.g. actuators, sensors or combinations of both. In addition, the EP6222-0002 offers a further two digital inputs on the free pins of the M12 ports. A point-to-point connection is used between the box and the device. The EtherCAT Box is parameterized via the EtherCAT master. IO-Link is designed as an intelligent link between the fieldbus level and the sensor, wherein parameterization information can be exchanged bidirectionally via the IO-Link connection. The parameterization of the IO-Link devices with service data can be done from TwinCAT via ADS or very conveniently via the integrated IO-Link configuration tool. In the standard setting, the EP6222-0002 functions as a 2-channel input module, 24 V DC, which communicates with connected IO-Link devices, parameterizes them and, if necessary, changes their operating mode. Each IO-Link port can optionally also be used as a pure input or output. The slim design enables use even in confined spaces.

The EP7402-0067 EtherCAT Box offers two outputs with integrated MDR controller for the direct connection of 48 V DC conveyor roller motors or other BLDC motors with max. 3.5 A. Eight additional digital inputs/outputs enable connection of e.g. photoelectric switches and communication between the box modules in operation without PLC.

The EPP1098-0001 EtherCAT P Box with digital inputs acquires the binary control signals from the process level and transmits them, in an electrically isolated form, to the controller. The state of the signals is indicated by light emitting diodes. The signals are connected via M8 screw type connectors.

The EPP1816-0703 EtherCAT P Box with digital inputs acquires binary control signals from the process level and transfers them electrically isolated to the controller. The signal state is indicated by means of LEDs. The signal connection is established via spring-loaded connectors, optionally available in 1- and 3-pin versions. Thanks to the compact plug level, the EPP1816-0703 can transfer 16 signals from the field via EtherCAT in a very small space.

The EPP2339-0703 EtherCAT P Box has 16 digital channels, each of which can be operated as input or output. It is not necessary to configure whether a channel is to be used as input or output. The input circuit is permanently connected to the output driver internally so that a set output is also automatically displayed in the input process image.

The EPP3048-0002 EtherCAT P Box has 8 channels and processes 20 mA standard signals with 16-bit resolution and up to 2000 measured values per second. Each channel can be parameterized individually via the controller/TwinCAT; signals in the range of -20…+20 mA , 0…+20 mA and 4…+20 mA can be processed by each channel. The current inputs are designed as single-ended. With a technical measuring range of ±107 % of the nominal range, the module also supports commissioning with sensor values in the limit range and evaluation in accordance with NAMUR NE43. Two channels are connected via an M12 socket.

The EPP3754-0702 EtherCAT P Box has four analog multi-functional inputs, which can be parameterized individually and extensively:

The SCT4xxx differential current transformers were designed for detecting differential currents (earth fault currents) type A. A differential current measurement can already detect very low error currents as well as various leakage currents. Continuous monitoring is necessary to be able to separate these from each other. This allows early detection of changes that may be indicative of degenerating insulation. The SCT4xxx differential current transformers thus enable condition-based maintenance and save operators the increased costs of previous blind maintenance intervals.

The SCT4xxx differential current transformers were designed for detecting differential currents (earth fault currents) type A. A differential current measurement can already detect very low error currents as well as various leakage currents. Continuous monitoring is necessary to be able to separate these from each other. This allows early detection of changes that may be indicative of degenerating insulation. The SCT4xxx differential current transformers thus enable condition-based maintenance and save operators the increased costs of previous blind maintenance intervals.

The SCT4xxx differential current transformers were designed for detecting differential currents (earth fault currents) type A. A differential current measurement can already detect very low error currents as well as various leakage currents. Continuous monitoring is necessary to be able to separate these from each other. This allows early detection of changes that may be indicative of degenerating insulation. The SCT4xxx differential current transformers thus enable condition-based maintenance and save operators the increased costs of previous blind maintenance intervals.

The SCT4xxx differential current transformers were designed for detecting differential currents (earth fault currents) type A. A differential current measurement can already detect very low error currents as well as various leakage currents. Continuous monitoring is necessary to be able to separate these from each other. This allows early detection of changes that may be indicative of degenerating insulation. The SCT4xxx differential current transformers thus enable condition-based maintenance and save operators the increased costs of previous blind maintenance intervals.

The SCT4xxx differential current transformers were designed for detecting differential currents (earth fault currents) type A. A differential current measurement can already detect very low error currents as well as various leakage currents. Continuous monitoring is necessary to be able to separate these from each other. This allows early detection of changes that may be indicative of degenerating insulation. The SCT4xxx differential current transformers thus enable condition-based maintenance and save operators the increased costs of previous blind maintenance intervals.

The SCT4xxx differential current transformers were designed for detecting differential currents (earth fault currents) type A. A differential current measurement can already detect very low error currents as well as various leakage currents. Continuous monitoring is necessary to be able to separate these from each other. This allows early detection of changes that may be indicative of degenerating insulation. The SCT4xxx differential current transformers thus enable condition-based maintenance and save operators the increased costs of previous blind maintenance intervals.

The SCT4xxx differential current transformers were designed for detecting differential currents (earth fault currents) type A. A differential current measurement can already detect very low error currents as well as various leakage currents. Continuous monitoring is necessary to be able to separate these from each other. This allows early detection of changes that may be indicative of degenerating insulation. The SCT4xxx differential current transformers thus enable condition-based maintenance and save operators the increased costs of previous blind maintenance intervals.

The AX1000 economy servo drive for implementing demanding and cost-sensitive drive tasks.

The variable frequency drives in the AF1000 series are particularly suitable for performing basic drive tasks cost-effectively.

With B/SSD, it is possible to monitor the state of systems and servomotors in real time with minimal effort.

The AX8820 universal regenerative unit is used to feed regenerative energy back into the supply mains.

The AM8300 synchronous servomotors with integrated water cooling are suitable for applications with extreme demands on performance and dynamics.

Stepper motors with an integrated stepper motor output stage for low-voltage control cabinet-free machinery concepts.

The AM8121 low-voltage servomotor is suitable for highly dynamic drive solutions in compact design in the voltage range of < 50 V DC. The standstill torque of the motor depends on the winding and is in the range of < 1.5 Nm. It is available with the OCT feedback system (absolute encoder). The low-voltage servomotor with flange code F2 (58 mm) and motor length 1 has a shaft diameter b = 9 k6 and a free shaft end of d = 20 mm.

The AM8123 low-voltage servomotor is suitable for highly dynamic drive solutions in compact design in the voltage range of < 50 V DC. The standstill torque of the motor depends on the winding and is in the range of < 1.5 Nm. It is available with the OCT feedback system (absolute encoder). The low-voltage servomotor with flange code F2 (58 mm) and motor length 3 has a shaft diameter b = 9 k6 and a free shaft end of d = 20 mm.

The integrated AMI8121 servo drive combines servomotor, output stage and fieldbus connection in a space-saving design in the voltage range of < 48 V DC. It is suitable for all motion requirements in the power range up to 400 W. The standstill torque of the motor is 0.5 Nm. The integrated servo drive with flange code F2 (58 mm) and motor length 1 has a shaft diameter b = 9 k6 and a free shaft end of d = 20 mm.

With the EcoLine motor modules, the modular XTS system makes intelligent product handling even more economical.

With TwinCAT PLC++, Beckhoff is delivering a new generation of PLC technology that accelerates both engineering and runtime.

Beckhoff has developed TwinCAT Chat for the TwinCAT XAE engineering environment.

Beckhoff presents the latest generation of motion software solutions in TwinCAT MC3.

Linux® distribution from Beckhoff lays foundation for new type of runtime

The TE1402 TwinCAT 3 Target for Embedded Coder® is an extension of the TE1400 TwinCAT 3 Target for Simulink®. Building on the existing capabilities of the TwinCAT 3 Target for Simulink®, which uses the Simulink® Coder™ (GRT target) from MathWorks for automatic code generation, the TE1402 also makes it possible to use the Embedded Coder® (ERT target) from MathWorks. The TE1402 essentially leverages the functions of the TE1400 while also harnessing the properties of the Embedded Coder® to achieve target platform specialization. For example, CPU-specific command extensions can be used to make models created on the Beckhoff Industrial PC run faster.

The TwinCAT 3 Simulation Runtime for FMI provides an interface for simulation tools that support the Functional Mockup Interface (FMI). The interface is based on the TwinCAT 3 UserMode Runtime, which can be accessed in sync from the simulation tool. This is exported to an FMU together with an interface description configured in TwinCAT, and can be imported into any simulation tool that supports the FMI interface as a co-simulation. Support is offered for both FMI 2.0 and 3.0. The TwinCAT project that is being executed in the FMU can also be part of the FMU; however, it is also possible to connect to this UM runtime with a TwinCAT engineering system and monitor or modify the code executed in the FMU in TwinCAT.

The TwinCAT 3 Machine Learning Creator automatically creates AI models based on data sets. These AI models can be optimized in terms of their accuracy and latency to ensure they run efficiently on Beckhoff Industrial PCs with TwinCAT products. The generated models can also still be used as standardized ONNX models beyond the Beckhoff product range. For use with TwinCAT products, a PLCopen XML with IEC 61131-3 code is created in addition to the ONNX file, which describes the complete AI pipeline and can be imported seamlessly into TwinCAT.

The TwinCAT 3 UI Client can display web applications such as the TwinCAT HMI or the Beckhoff Device Manager. No additional browser is required on the client system. The TwinCAT 3 UI Client can be operated as a desktop application or in kiosk mode.

TwinCAT 3 CNC Online Adaption allows customer-specific interpolation functions to be implemented in C++ and integrated into the TwinCAT CNC real-time stack via TcCom interfaces. Three different functions are currently available for influencing tool radius compensation (TRC), dynamic contour control (DCC), and geometric feed adjustment (GFA).

TwinCAT 3 CNC Extended Interpolation allows two independent interpolation paths to be programmed within a CNC channel (two-path programming) and provides functions for synchronization and compensation of the paths.

TwinCAT 3 CNC AM Plus extends TwinCAT CNC with functions for predictive control for external processes, as is usual in additive manufacturing. To this end, it provides a PLC interface that can be used to determine future contour elements and their parameters. This function also includes an ADS interface for querying the dynamic values of individual axes at any point in time in the future.

TwinCAT 3 CNC EDM Plus unites the functions from TF5262, TF5263, and TF5291 in one package and is thus the perfect basis for PC-based control for complex wire-erosion machines and die-sinking machines. It also includes technology-specific functions, such as optimized retraction strategies for sink electrodes or compensation mechanisms that take wire wear into account.

The VUI20x0 is a complete unit with IP65/IP67 protection comprising a camera, illumination, and focusable optics complete with liquid lens technology. It generates high-quality monochrome images for industrial image processing applications. Power is supplied via EtherCAT P. As a full-featured device, the unit can be synchronized with all EtherCAT-based machine processes. The image data is transmitted to the higher-level controller with a bandwidth of 2.5 Gbit/s. The light color and pulse intensity of the integrated multicolor LED ring illumination can be adjusted to the product via the control. The focus is adjusted during runtime via the liquid lens control.

The VUI20x1 is a complete unit with IP65/IP67 protection comprising a camera, illumination, and focusable optics complete with liquid lens technology. It generates high-quality color images for industrial image processing applications. Power is supplied via EtherCAT P. As a full-featured device, the unit can be synchronized with all EtherCAT-based machine processes. The image data is transmitted to the higher-level controller with a bandwidth of 2.5 Gbit/s. The light color and pulse intensity of the integrated multicolor LED ring illumination can be adjusted to the product via the control. The focus is adjusted during runtime via the liquid lens control.

The VUI20x0 is a complete unit with IP65/IP67 protection comprising a camera, illumination, and focusable optics complete with liquid lens technology. It generates high-quality monochrome images for industrial image processing applications. Power is supplied via EtherCAT P. As a full-featured device, the unit can be synchronized with all EtherCAT-based machine processes. The image data is transmitted to the higher-level controller with a bandwidth of 2.5 Gbit/s. The light color and pulse intensity of the integrated multicolor LED ring illumination can be adjusted to the product via the control. The focus is adjusted during runtime via the liquid lens control.

The VUI20x1 is a complete unit with IP65/IP67 protection comprising a camera, illumination, and focusable optics complete with liquid lens technology. It generates high-quality color images for industrial image processing applications. Power is supplied via EtherCAT P. As a full-featured device, the unit can be synchronized with all EtherCAT-based machine processes. The image data is transmitted to the higher-level controller with a bandwidth of 2.5 Gbit/s. The light color and pulse intensity of the integrated multicolor LED ring illumination can be adjusted to the product via the control. The focus is adjusted during runtime via the liquid lens control.

The TwinCAT 3 Vision Beckhoff Camera Connector offers the option of integrating Beckhoff cameras directly into the TwinCAT architecture. The cameras are configured in the same development environment as fieldbus components or axes. Triggered from real time, image acquisition and PLC or motion can be run with a high degree of synchronicity.

TwinCAT 3 Vision Code Quality complements the basic package with functions for quality evaluation of various 1D and 2D codes. Evaluation is carried out in accordance with the ISO/IEC 15415 and ISO/IEC 15416 standards.

TwinCAT 3 Vision OCR contains functions for optical character recognition (OCR). The functions identify characters in an image and return the recognized character string.

TwinCAT 3 Vision Neural Network provides an integrated machine learning (ML) solution for vision-specific use cases. The implementation of the machine learning models takes place in real time. With the help of these models, complex data analyses can be learned automatically. This means that complex, manually created program constructs can be replaced.

When you click on "Accept", we show the video and adjust the privacy settings; external content from Video is loaded during this process. Please refer here to our Privacy Policy.

In order to continue to use myBeckhoff, you need to agree to the export control and sanctions compliance terms.

If you do not agree to these terms, you will automatically be logged out of myBeckhoff.