From 4 to 10 of May, Interpack 2017 has shown the latest in packaging technologies. As motion and packaging specialists, Beckhoff offers solutions that were in focus not just at one, but at several trade show booths: with the XTS eXtended Transport System. Combining the principles of linear and rotary drives, the XTS enables completely new machine designs for food packaging, taps new potentials in non-food packaging and allows for new solution approaches in cosmetics packaging, for example.

More about this video

XTS i „Hygienic Design“ til Motionløsninger, der er kompakte, yderst fleksible og nemme at rengøre

Det eXtended Transport System fra Beckhoff åbner i form af denrustfrie ståludførelse XTS Hygienic et bredt spektrum af nyeanvendelsesmuligheder, i særdeleshed inden for levnedsmiddelogmedicinalindustrien såvel som til fremstilling eller tapning afvæsker. Med den høje kapslingsgrad IP 69K, med den meget godekemiske holdbarhed og uden skjulte hjørner, kanter ellerunderskæringer har varianten i „Hygienic Design“ et særlig stortinnovationspotentiale. Fordelene ved standardudførelsen somhøjfleksibel Motion-løsning forenes med en enkel rengøring ogmuliggør således procesoptimeringer og en maksimalanlægstilgængelighed, også ved høje krav til hygiejne.

XTS | Linear product transport

As an intelligent transport system, the eXtended Transport System enables flexible motion profiles and new types of machine concept.

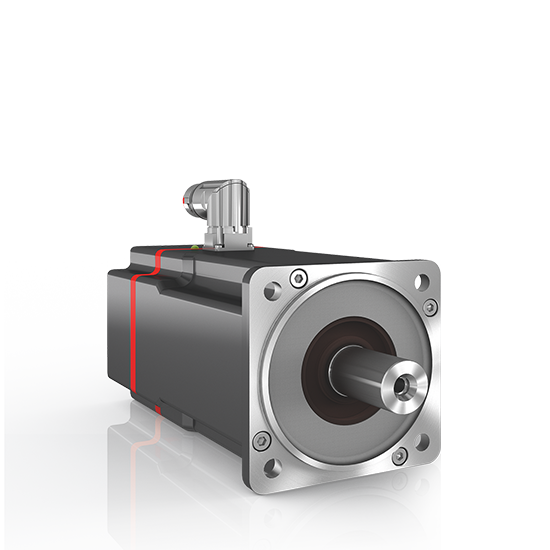

Motion

Our innovative drive technologies give you almost unlimited capabilities when it comes to realizing your application.

Packaging machines

PC-based control significantly increases the productivity and flexibility of packaging machines and lowers the consumption of resources.