From 4 to 10 of May, Interpack 2017 has shown the latest in packaging technologies. As motion and packaging specialists, Beckhoff offers solutions that were in focus not just at one, but at several trade show booths: with the XTS eXtended Transport System. Combining the principles of linear and rotary drives, the XTS enables completely new machine designs for food packaging, taps new potentials in non-food packaging and allows for new solution approaches in cosmetics packaging, for example.

More about this video

XTS in “Hygienic Design” for compact and highly flexible motion solutions with optimal cleanability

XTS Hygienic, the stainless steel version of the eXtended Transport System from Beckhoff, opens up a wide spectrum of new applications, first and foremost in the primary food and pharmaceutical industries and for processing and filling liquids in general. Enabling optimal cleanability with the high protection rating of IP 69K, very good chemical resistance and without any hidden corners, edges or undercuts, the version in Hygienic Design offers a lot of potential for innovation in these industries. The advantages of the standard system as a highly flexible motion solution are combined with ease of cleaning, thus enabling process optimisations and maximum production line availability even when the demands made on hygiene are high.

XTS | Linear product transport

As an intelligent transport system, the eXtended Transport System enables flexible motion profiles and new types of machine concept.

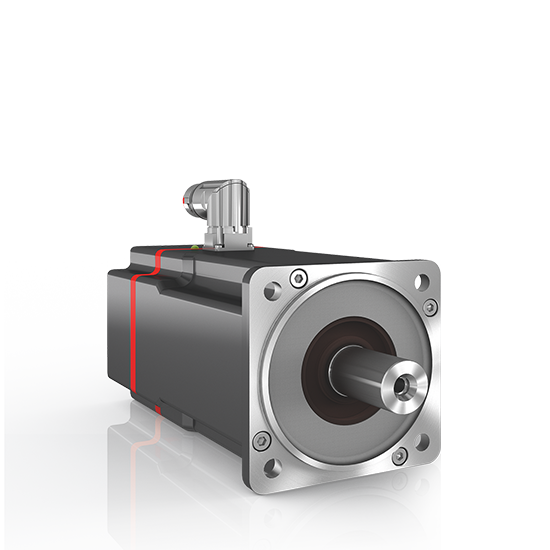

Motion

Teknologi drive kami yang inovatif memberi Anda kemampuan yang hampir tidak terbatas dalam mengimplementasi aplikasi Anda.

Packaging machines

PC-based control significantly increases the productivity and flexibility of packaging machines and lowers the consumption of resources.