XTS for increased flexibility and performance in the production of beverage packaging

The typical beverage cartons that Tetra Pak produces for milk, fruit juices, and more are familiar to virtually all of us. Although they are efficient and robust to transport and use, they place significant demands on production technology. Key to the company’s processes are quality, system output, and process flexibility – and the Development & Technology experts at Tetra Pak in Modena, Italy, have used the XTS linear transport system from Beckhoff to achieve all of these in a new machine for cap application onto carton packaging. The system has been so successful that Tetra Pak’s pilot customer, impressed by its reliability, performance, and flexibility, has described it as a “magic machine.”

Tetra Pak is a world leading food processing and packaging solutions company. Its aim is to work with customers and suppliers to give hundreds of million of people in over 160 countries access to safe and nutritious food, every day – with minimal environmental impact. At the company’s Modena location, the team has achieved this with the Tetra Pak® Cap Applicator 40 Speed Hyper. The solution is able to apply caps as needed to as many as twenty-five thousand beverage cartons per hour. Gianmarco Di Eusebio, Product Owner at Tetra Pak, explains: “When it comes to new developments, we believe it is always very important to listen to our customers carefully. In this case, a more flexible machine with reduced space requirements and a higher system output was needed. Current solutions for portion packages run at 9,000 units per hour – so achieving the required twenty-five thousand would have meant installing three machines, each with a feeding system and so on, and finding the space to go along with that.” He adds that the requirements placed on the new machine were very demanding, partly due to the high processing rate and partly due to the 3D geometry of the cap, which requires extremely high quality standards to be met when applying the adhesive.

PC-based solution overcomes limitations and increases data transparency

Tetra Pak opted for PC-based control technology from Beckhoff due to its high computing power; this was a significant factor in the decision. Paolo Scarabelli, Director Innovation, Analytics & Line Solutions at Tetra Pak, mentions an important aspect of this: “Our customers are increasingly demanding systems with a high degree of digitalization and connectivity. The PC-based control technology from Beckhoff forms the ideal basis for this. XTS also makes it easy to replace work that used to be mechanical with software functions, representing an additional step towards creating a digitalized machine. With the Tetra Pak® Cap Applicator 40 Speed Hyper, for example, we were able to shift the boundary between digital and mechanical machine components in favor of digitalization. In our specific case, this means that we have full digital control of more machine functions and can therefore operate the system more reliably.”

Overall, the higher level of digitalization offers great data transparency, leading to significantly faster product changeovers and improved quality, as Fabio Bassissi, Technology Specialist at Tetra Pak, explains: “The XTS movers can be controlled as individual servo axes, allowing new product formats to be introduced very easily and quickly, leveraging software flexibility. In addition, we can compensate for any mechanical tolerances very effectively in conjunction with the vision system for adhesive monitoring.” If the visual inspection reveals that the adhesive is no longer being applied in the ideal position, the software switches to other cam plates for the coupled mover pairs during operation and the adhesive is applied on the desired path again. Fabio Bassissi continues: “We also use asset health monitoring to check the state of our equipment. All of this is crucial to quality assurance and, as such, to the success of the product. Ultimately, beverage containers can only be sent to end customers if they are completely leak-tight and reliably sealed.”

Reliable control of highly complex motion sequences

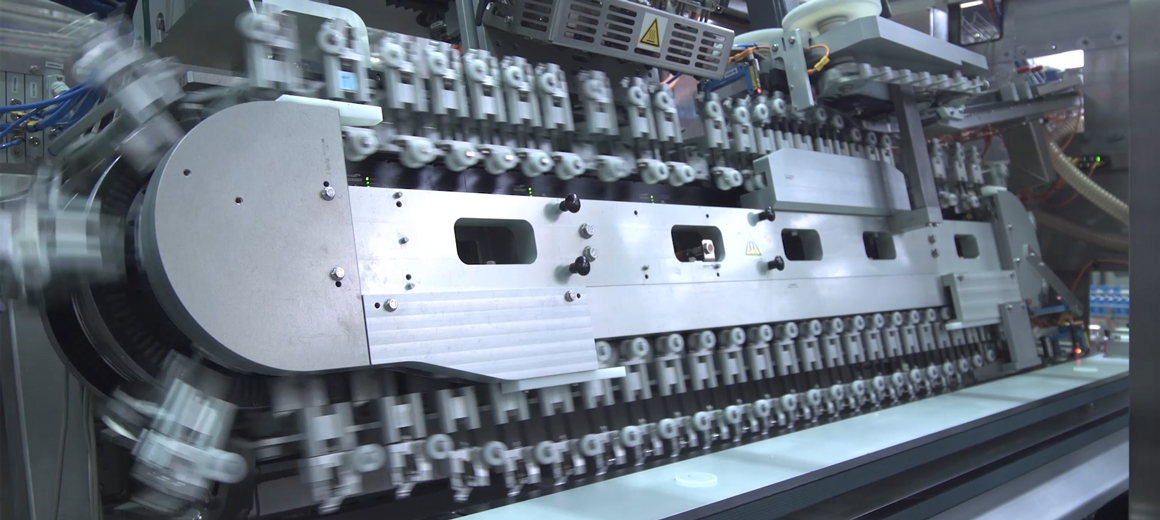

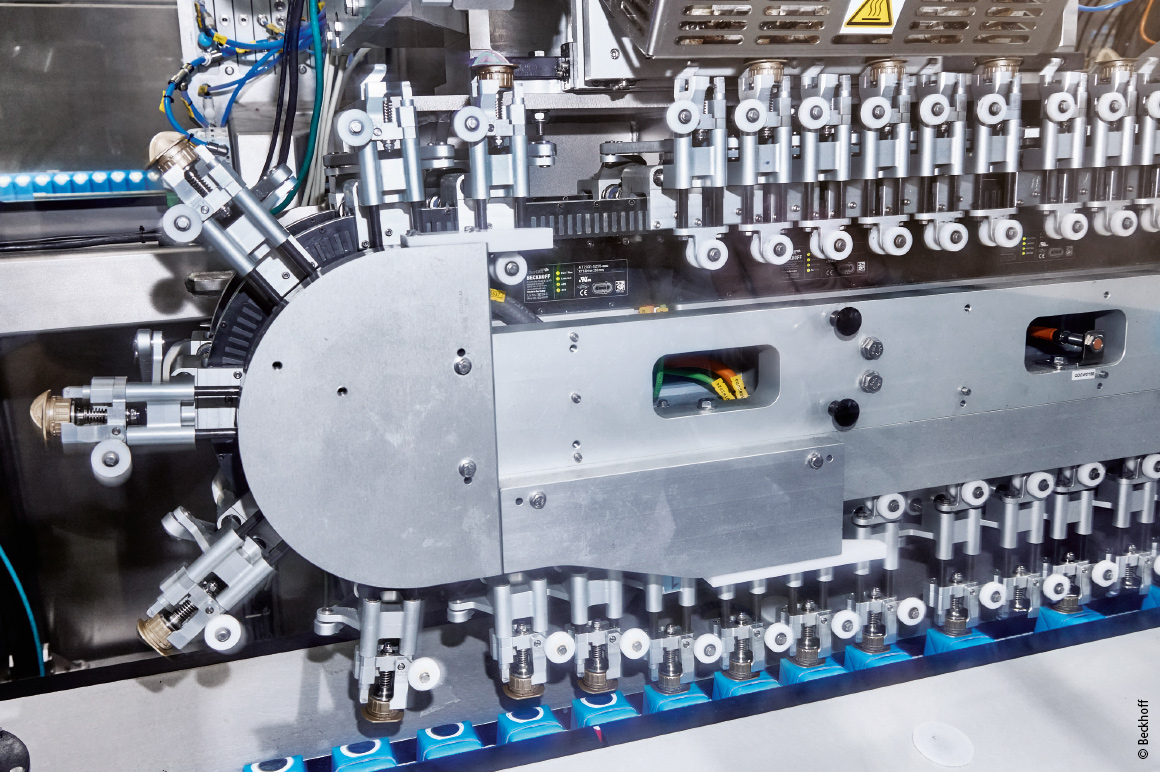

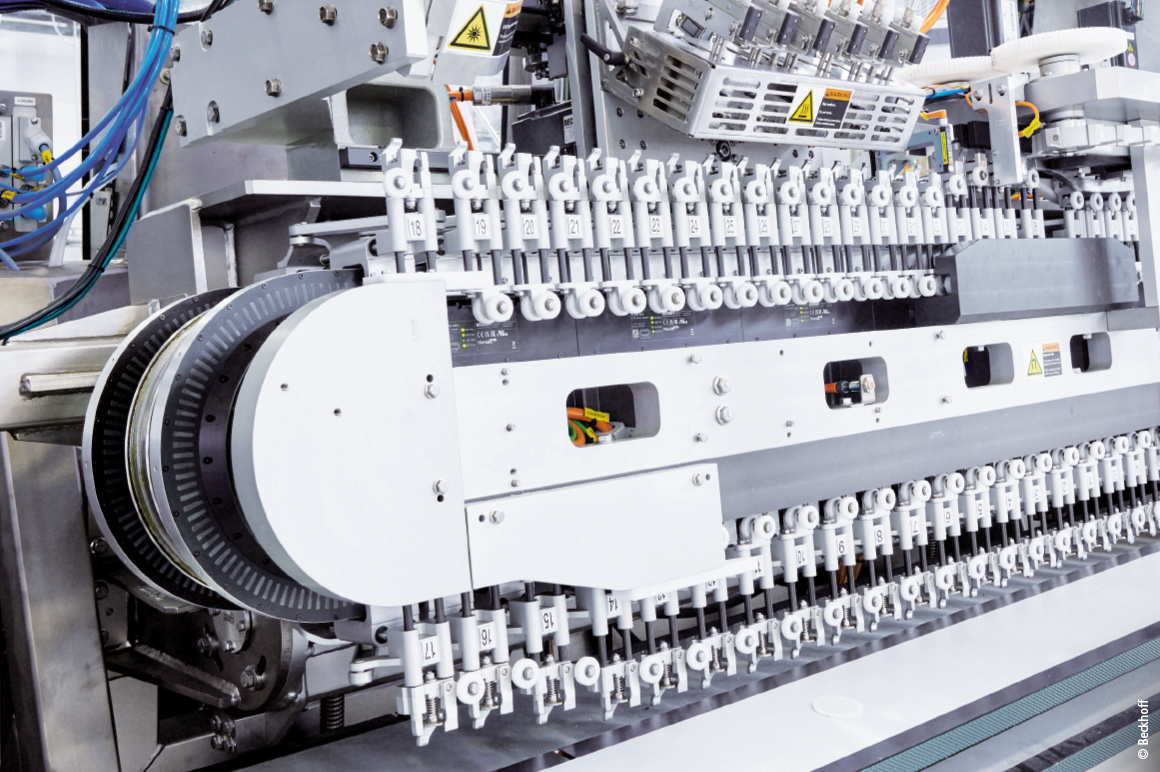

Even the high number of axes associated with the Tetra Pak® Cap Applicator 40 Speed Hyper – over 120 real axes and 10 virtual master axes – illustrates how complex the motion control process is. The majority of the axes use two parallel XTS tracks, each 4.5 m long and with 55 movers. There are also around ten rotary servo axes used for tasks such as packaging transfer and hot melt application.

In order to glue on the cap correctly, given its 3D geometry, the movements of the XTS movers and the various rotational movements in the X, Y, and Z directions must be synchronized precisely. The special feature here is that each pair of movers is connected by the tool structure, but runs on the two XTS units mounted in parallel to one another. It does not matter whether the movers are on one system arranged in a row or on two different systems, and the control software takes advantage of this – it always moves the movers in complete synchronization with each other. According to Stefano Flore, Director Packaging Lines Embedded Automation at Tetra Pak, XTS generally offers a very high degree of flexibility due to its modular design and excellent software functions. The ability to change the XTS track length and the number of movers, for example, means that hardly any work is involved in creating machine variants with a higher or lower product output. It is also very easy to change over to different packaging formats to accommodate other fill quantities and differently shaped pack tops or caps, for example. In the software, new settings only need to be configured for the distances between the coupled movers and the movement specifications on the two XTS systems.

Stefano Flore also makes it clear that the XTS movers with individual control offer far more functionality than just product transport: “After the caps have been picked up by the corresponding brackets on the movers, up to six synchronized movers form a batch in order to apply the adhesive profile. For this purpose, the cap bracket moves on the X-axis and Y-axis by means of a mechanical coupling with the associated mover of the parallel XTS system. At this point, the system compensates for any tolerances, such as those caused by the adhesive nozzle. The cap is then applied to the carton packaging with precision and monitored by means of image processing. XTS also assists in making the gluing process error-free by maintaining the correct contact pressure using a precisely defined level of transverse force in the mover.” This force is generated by the precise interaction between the two coupled gantry movers. Another major advantage of XTS over mechanical systems is that a large amount of information is available centrally in the software. Deviations from the system parameters can not only be localized very quickly, but also completely avoided by taking countermeasures. On the subject of faults, Gianmarco Di Eusebio adds: “The mean time between failures (MTBF) has more than doubled with this system.”

Control technology offers consistently high performance

Tetra Pak also chose to use control technology from Beckhoff because all of the system-related components are available from a single source, guaranteeing seamless and efficient integration. At the heart of the machine control system are two C6032 ultra-compact Industrial PCs for the HMI applications, the two XTS systems, motion control with TwinCAT NC PTP, and TwinCAT PLC. In addition, a wide range of functions can be combined in a single control unit, including machine simulation. Additionally, the selected hardware platform offers plenty of potential for adding more functions in the future. What’s more, Beckhoff provides an extremely wide, finely scalable portfolio in terms of computing power, memory expansion, and even form factor, ensuring that systems stay fit for the future.

When discussing his experience with TwinCAT software, Paolo Scarabelli says: “TwinCAT allows the potential of PC-based control to be exploited to the full. This ranges from a wide variety of programming languages, including object-oriented languages, to integration in Visual Studio and comprehensive network configuration options, all the way through to excellent multi-core support. In addition, the software is well structured and its open nature makes it possible to not only use the extensive Beckhoff function libraries, but also seamlessly integrate your own libraries to create machine-specific condition monitoring. We also make intensive use of TwinCAT Scope for development-related analyses. Overall, TwinCAT gives us the best possible support, including when it comes to achieving our goal of standardized software development.”

He adds that the openness and flexibility of PC-based control play a major role in this area as a whole: Ideal support is provided by the powerful and open EtherCAT communication system, which seamlessly integrates the I/O terminal segment, functional safety, and drive technology. As Stefano Flore states: “The AX8000 offers clear advantages due to the very high dynamics and precise control of the motion sequences. In addition, the modular design is extremely compact and flexible, allowing additional axes to be added easily if required. This is supported by the wide range of AM8000 servomotors, whose motor type, power, winding type, and other aspects can be finely scaled.”

Comprehensive support and outstanding future potential

Davide Borghi, Manager of Advanced Analytics for Equipment at Tetra Pak, confirms that the automation partner’s support is also vital when it comes to such demanding applications: “Support is particularly important when changing the machine concept. For the Tetra Pak® Cap Applicator 40 Speed Hyper, this came into play right from the point when feasibility testing was performed, and was especially useful for configuring the XTS system and its huge range of functions. Support was provided flawlessly in all cases – on-site with Beckhoff Italy and the experts in Germany, and right up to each of the management levels involved.”

The strong collaboration is set to continue in the future, as Stefano Flore continues to see great potential for the use of PC-based control in Tetra Pak® equipment: “We believe that No Cable Technology (NCT) is a promising further development for XTS. We are already testing the possibilities that XPlanar can bring to a number of applications. We also see attractive advantages of the MX-System for control cabinet-free automation and of TwinCAT Runtime for Linux®. So there is a great deal of potential to surprise users – like the pilot customer in this case – by giving them a ‘magic machine’.”