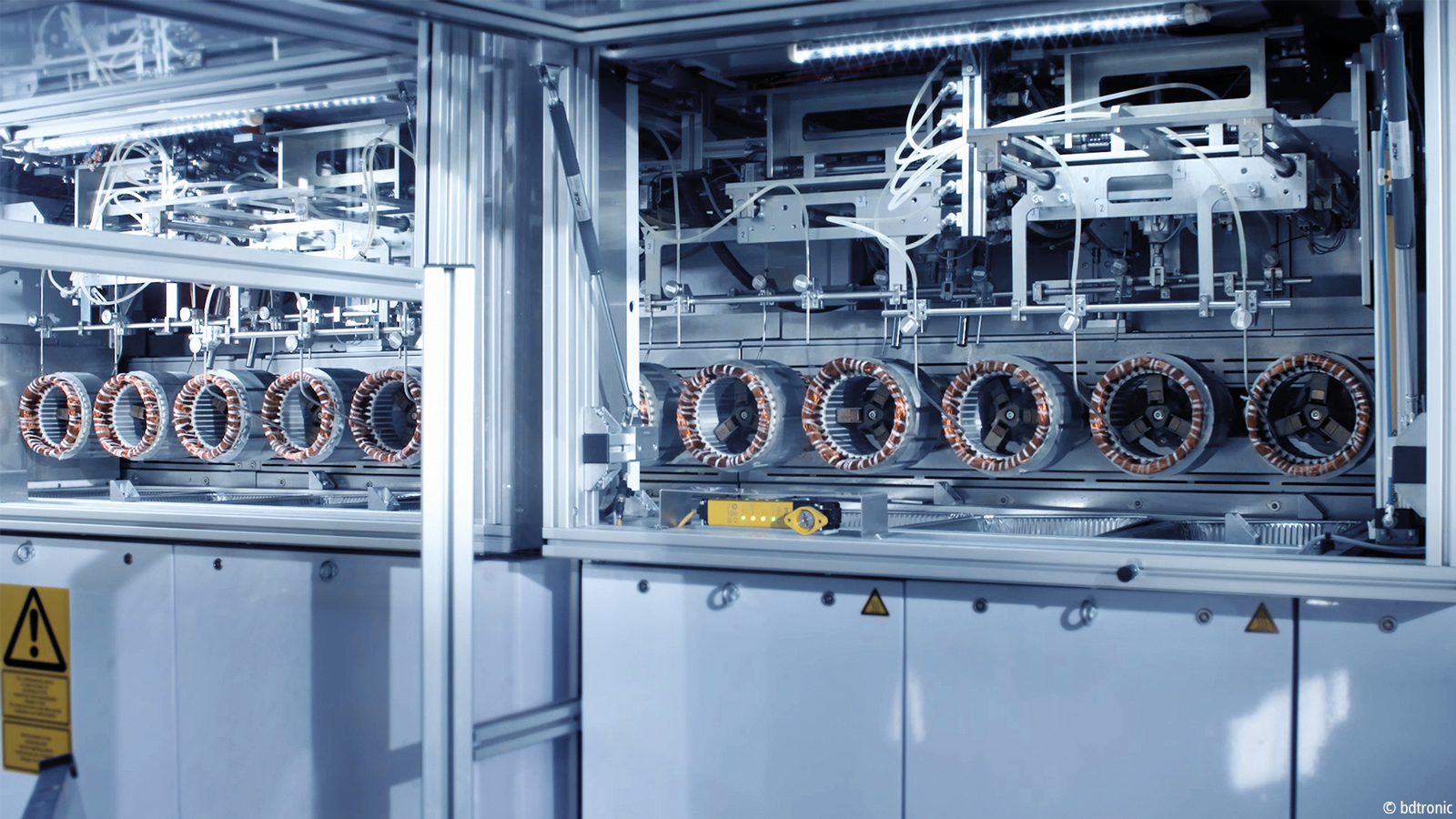

PC-based control for trickle impregnation systems for electric motor production

Potting the windings is crucial for the performance and durability of electric motors. This is why many car manufacturers rely on impregnation systems from bdtronic. The process solution provider from Weikersheim combines its comprehensive process expertise in the dispensing, plasma, impregnation and heat staking technology into individual, cycle time-optimized systems with the help of PC-based control from Beckhoff.

The higher the degree of filling of the impregnating resin in the slots of a stator/rotor, the better the thermal dissipation and mechanical stability of the motor winding, which, in turn can improve the performance of the electric drive. Therefore, to develop high-performance impregnation systems, system providers must possess in-depth process expertise about material preparation, dispensing and curing of resins. Manufacturing dispensing and impregnation systems since the seventies, bdtronic now boasts eight service and sales branches worldwide. More than 580 employees dedicate their time to developing and producing machines and systems for the electronics industry, for the production of batteries for electric vehicles, and sensor technology for autonomous driving. The process solutions are used for single-component and two-component dispensing, prior plasma treatment, heat staking and impregnation for electric drives. “Nearly all of the world’s leading OEMs produce their motors using trickle technology from bdtronic,” explains Markus Rieger, Director of Indirect Sales and Marketing at bdtronic.

From dipping to efficient trickling

When dipping, the stators/rotors of electric motors are immersed in an open basin with resin until all cavities are filled. This is followed by an elaborate process of removing the resin from the bundle of laminations of the electric motors. “This is both cost-intensive and unsustainable in terms of material consumption and environmental and operator protection,” explains Florian Schütz, Regional Sales Manager DACH at bdtronic.

In contrast, trickling is an impregnation process: The systems apply the impregnation material precisely and in the required quantity at pre-determined positions. The resin flows between the stator housing and the winding and hardens under defined process conditions. “We have developed and refined the trickling process as a sustainable and cost-effective alternative to the usual dipping process,” emphasizes Andreas Olkus, Managing Director of bdtronic.

The main advantage for customer applications? The precise interaction of automation and dispensing technology. bdtronic’s very own Technology Center is responsible for developing the process for large-scale production. The parameters determined by the center are transferred to large-scale production to build suitable system. “Our expertise helps to automate the process so that it works perfectly and is reproducible under a wide range of production conditions,” says Global Head of Development André Hellinger.

Sophisticated motion control

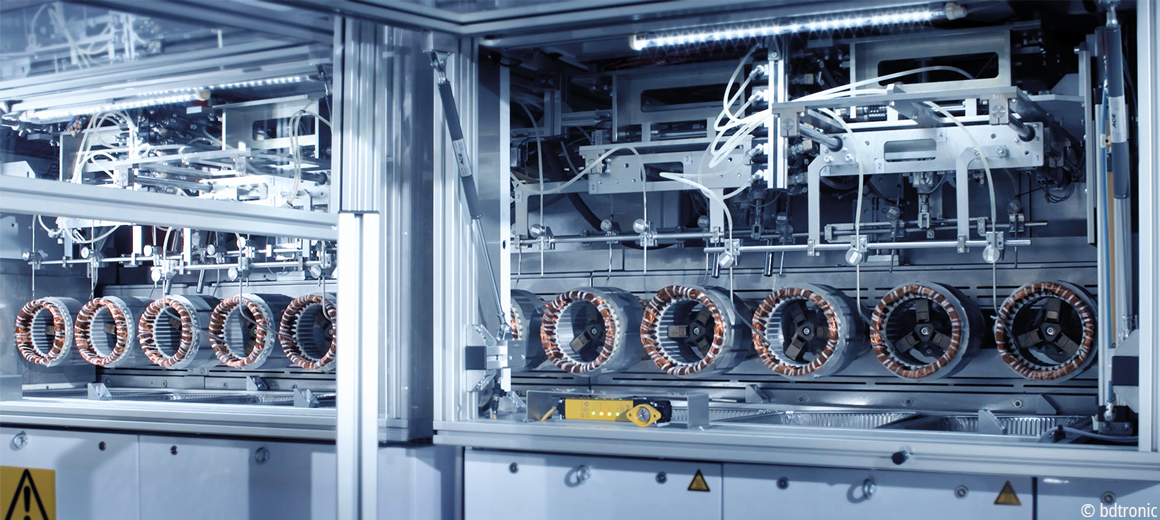

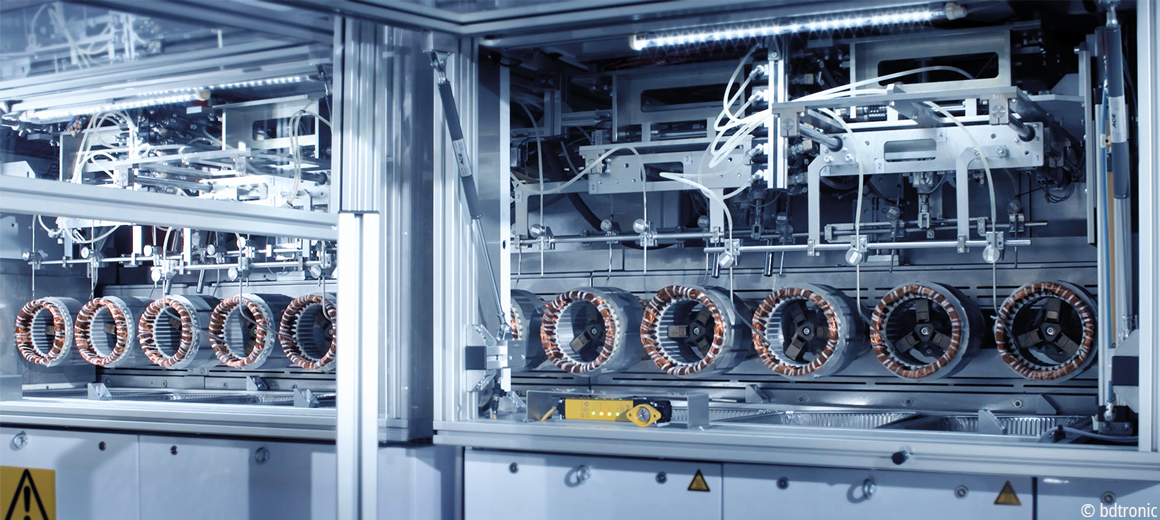

At the beginning of the overall process, a robot picks up three stators/rotors and fixes them onto tool holders. These holders are then guided via a transport chain through the roughly 13-m long system. In a first step, the stators/rotors are preheated to around 100 °C , before trickling begins at around 50 servo-controlled trickling stations. This is followed by gelling and curing zones with temperatures of up to 180 °C as well as final cooling zones. At the end of the system, another robot removes the stators/rotors and prepares them for the next processing steps.

To ensure that all grooves are completely filled and the resin does not drip, the stators/rotors must rotate continuously as they pass through the system. The sheer number of dispensing pumps and rotating tool holders on the chain alone are an indication of the sophisticated motion sequences that are implemented using the TwinCAT 3 software from Beckhoff. A challenging factor is that the chain expansion varies constantly in the different temperature zones. The dispensing needles are positioned with an accuracy of ±0.1 mm to the rotating stators/rotors. In addition, the trickling station servo pumps must be controlled synchronously with the movements. Even the rotation of the stators/rotors is precisely controlled to maintain a constant rotation speed in the transport chain curves. “We have invested a lot of time and energy into the software and the motion profile in terms of positioning and component rotation in relation to the chain,” emphasizes Karsten Bauer, Head of Software and Electrical Design.

Keywords: tracking and tracing

“Temperature and dispensing quantity are very important factors for the perfect dispensing and trickling process,” highlights Antonia Anetzberger, Product Manager for Dispensing Systems. bdtronic sets great store in being able to trace the complete process chain and offers maximum process reliability. This means that users know at all times where each stator/rotor is currently positioned in the system and the conditions under which it was impregnated. In addition, each stator/rotor is weighed before and after impregnation to document the amount of resin absorbed as a further quality criterion.

Customers can access such production data using a wide variety of interfaces or can directly connect the database to their own QM systems. “This is where the openness and the flexibility of PC-based control present an enormous advantage,” says Mirko Ammersbach, head of the Beckhoff sales office in Marktheidenfeld.

Scalable in terms of hardware and software

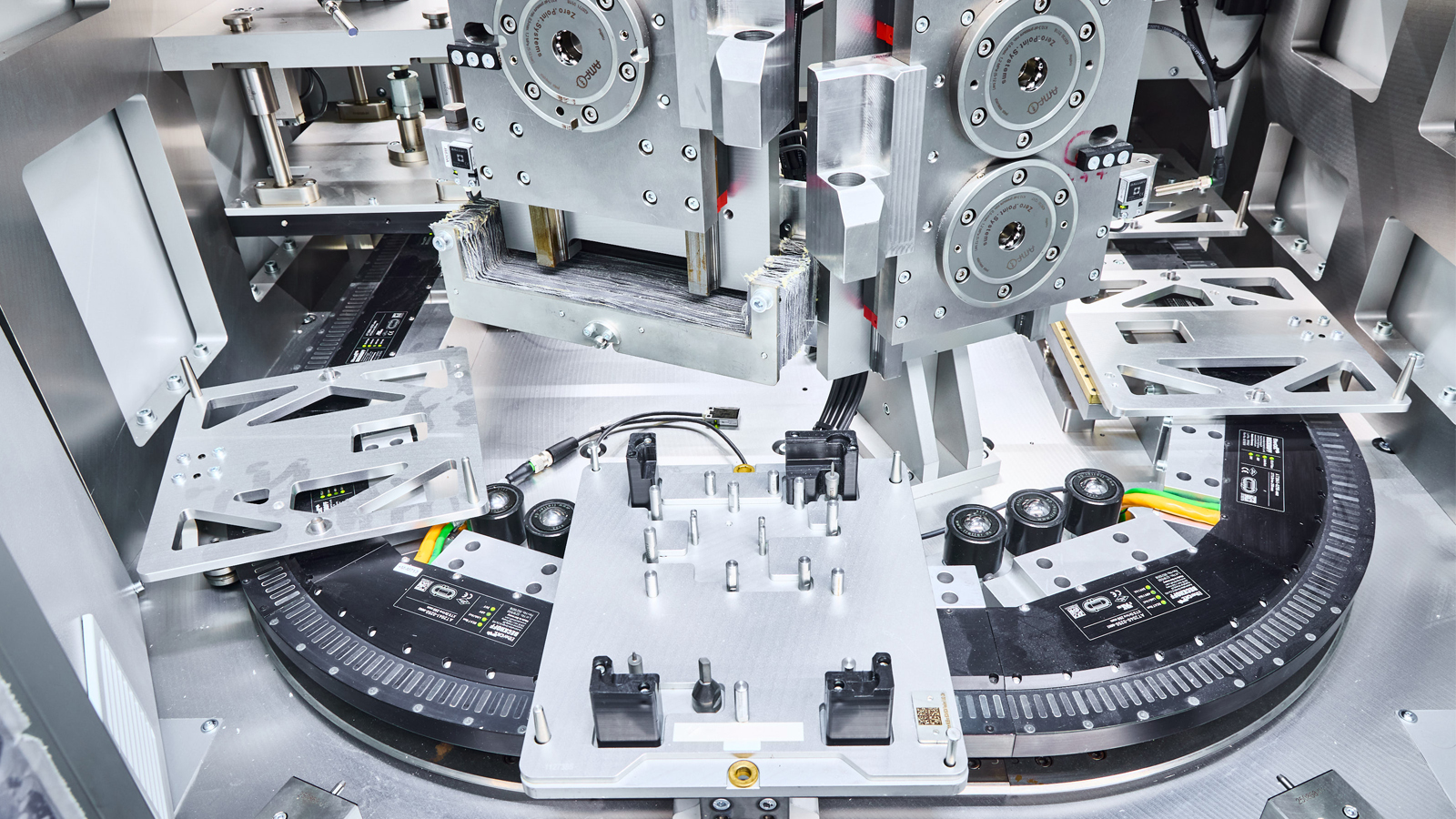

Machine builder bdtronic relies on almost the entire range of Beckhoff components in its various systems and scales the computer hardware according to the performance requirements. Components such as CX2033 Embedded PCs, C6930 control cabinet Industrial PCs, and C6040 ultra-compact Industrial PCs are integrated into the dispensing, plasma, heat staking and impregnation systems. To minimize the systems’ footprint, EtherCAT Box modules are used in addition to EtherCAT Terminals. “At the moment, system wiring and cabling still require a relatively large amount of space and time,” says Andreas Olkus. Beckhoff supports decentralization with the MX-System, the pluggable system solution for control cabinet-free automation as well as the AMP8000 distributed servo drive system, the AMI8100 integrated servo drives and the EP series EtherCAT Box modules.

Of equal interest are the XPlanar planar motor system for implementing new machine concepts, as well as Beckhoff Vision and ATRO (Automation Technology for Robotics). “If required, we can easily integrate these components into our control environment and adapt the performance of the industrial PCs to our liking,” says Karsten Bauer, highlighting the advantages of PC-based control.