Interview with I/O and smart grid expert Dr. Fabian Assion

The proportion of renewable energies – solar, hydropower, and wind – has increased significantly in recent years and had already accounted for more than half of Germany’s electricity feed in 2023. Dr. Fabian Assion, Product Manager I/O at Beckhoff, explains what this high share of highly fluctuating energy means for grid operation as well as for the required smart grids from a control technology perspective.

What role do smart grids play in the energy transition and what does this mean for grid management?

Dr. Fabian Assion: The increased proportion of renewable energies is making the supply grids more unstable for two reasons. The first reason is that this energy is generated in a much more distributed manner. It is no longer distributed as centrally as was previously the case with large power plants. This means that the existing physical grid structure is not as suitable as it used to be: The change in current flow sometimes leads to grid instabilities and overloads. The second reason is that traditional power plants are usually operated by synchronous generators. This is ideal for grid operation, e.g., by providing optimal grid support in the event of a ground fault. Renewable energies, however, are controlled by power inverters. Therefore, they can only provide the very high currents required in such cases to a limited extent, which also leads to grid instabilities. Today’s energy supply grids are therefore more complicated to control overall. And this is exactly what smart grids are used for: They have significantly more information on the current grid status and are therefore much easier to control.

What are the technical requirements of smart grids in terms of extended measurement technology, for example?

Dr. Fabian Assion: Additional measurement technology has to be installed at all grid levels. To date, this has primarily been implemented in the ultra-high and high-voltage sectors, but hardly – if at all – in the medium and low-voltage sectors. The fact that the lower grid levels in particular need to be upgraded is of great importance from an investment perspective. This is because these levels are much, much more extensive than the upper sectors and therefore, accordingly, require many more measuring points. Hundreds of thousands of measuring points are needed even for a reasonably comprehensive approach. This is illustrated by the example of the local substation as the lowest link in the supply grid. This is where the medium voltage is transformed into low voltage, usually using a transformer with eight or more low-voltage outputs. These voltage outputs should all be equipped with measurement technology for a wide range of measured variables. And that’s the case for some 100,000 local substations in Germany.

And which metrics are relevant?

Dr. Fabian Assion: The current is of course the most important single value, but it doesn’t go far on its own. If possible, all types of power – reactive, apparent, and active power – should also be recorded at each outgoing feeder to make statements about the grid status. This is particularly important as the majority of loads now use a power supply unit and therefore generate undesirable harmonics. In other words, it is now almost essential for the grid operators responsible for grid quality to collect detailed data on harmonics and even on the level of each individual harmonic from each voltage output in order to take targeted measures if necessary.

What advantages does the PC and EtherCAT-based control technology from Beckhoff offer with its system-integrated measurement technology?

Dr. Fabian Assion: With PC-based control from Beckhoff, measurements can be performed using comparatively little technical effort and financial expense. What’s more, the measurement technology is high quality and easy to use. It is based on EtherCAT with its distributed clocks and is therefore sufficiently fast and precise to respond appropriately to short-term events in the grid. We would like to point out that due to our concept of distributed power measurement, high-quality measurement data can be generated particularly cost-effectively.

What exactly is behind the concept of distributed power measurement?

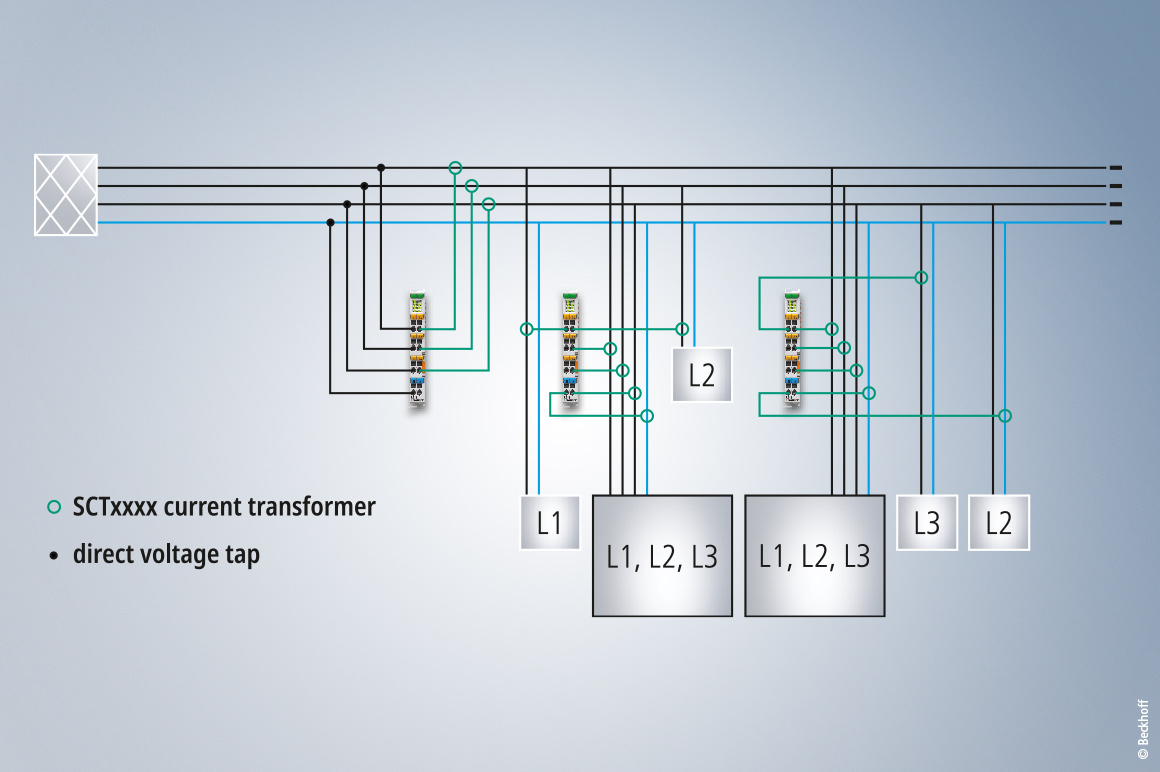

Dr. Fabian Assion: A key feature here is that all relevant electrical data from the supply grid, including real measured values for power – without local voltage measurement – can be determined with the EL3446 EtherCAT Terminal as a mere current measurement terminal. However, the EL3446 terminals distributed in the system as required receive the voltage values required for calculating the power data via EtherCAT from a separate EL3443 power measurement terminal, which only needs to be installed once and is precisely synchronized in time by the distributed clocks function in EtherCAT. This minimizes the hardware and installation costs required to reliably monitor the grid quality with a high-quality harmonic measurement at each outgoing voltage feed and the resulting power quality factor.

Solutions with PC-based control have already proven their worth many times over in areas such as the wind energy sector. What are the main advantages here?

Dr. Fabian Assion: More than 100,000 wind turbines up to a size of 16 MW have already been automated worldwide with our PC-based control technology. Once again, EtherCAT demonstrates its advantages here, as it enables very fast and precisely synchronizable control processes, allowing operation and energy yield to be optimized. This applies to individual wind turbines, even on a larger scale, but also to networking within a complete wind farm. In the case of offshore turbines, high-voltage direct current (HVDC) transmission is also one of the most sophisticated elements in a supply grid. PC-based control from Beckhoff has also been successfully implemented in this sector. This is illustrated by the Siemens Energy solution described in issue 02/2024 of our customer magazine PC Control.

Beckhoff technology not only demonstrates its advantages in the field of power generation, but also when it comes to distributing energy via regional supply grids. What efficiency potential can be tapped into?

Dr. Fabian Assion: In addition to the system-integrated measurement technology, users benefit greatly from the exceptionally broad range of Beckhoff I/O solutions for all application areas and environmental conditions. This means that all necessary data can be recorded and merged in the control system – for power measurement, but also for integrating telecontrol protocols, switch positions, signal messages, and transformer and ambient temperatures. The example of Romande Energie, an energy supplier in western Switzerland, shows just how much this can contribute to secure grid management (see PC Control, issue 04/2020).

Recording performance data is one aspect, stabilizing it is another. What solutions does PC-based control offer in terms of frequency control and stabilization?

Dr. Fabian Assion: Frequency control and stabilization in the energy supply grid is a very elaborate and complicated task. This requires not only comprehensive grid data, but also an extremely fast system response – in the millisecond and, at times, even in the microsecond range. The Korean company Power 21 successfully implemented this in 2015 for energy supplier KEPCO with a high-precision frequency measurement using our EL3773 grid monitoring terminal with oversampling function (see PC Control, issue 01/20216). Another example is how the Institute of Electrical Energy Systems and High Voltage Technology (IEH) at the Karlsruhe Institute of Technology (KIT) is researching ways to ensure system stability in the transmission grids that are changing as a result of the energy transition. In addition to investigative simulations, the behavior of power plants and inverter-based generation systems in an island grid is being simulated in a dedicated test environment. For this purpose, innovative new control methods are being carried out on Beckhoff Embedded PCs with TwinCAT, thereby validating their application in realistic scenarios (see PC Control, issue 03/2021).

What power consumption savings potential can regional consumers – especially larger industrial plants with their own supply grids – tap into?

Dr. Fabian Assion: Our own energy management system enables us to track loads and minimize costs by avoiding peak loads. This is of particular importance when establishing an in-house energy supply grid. And this applies not only to large industrial groups, but also to SMEs. As soon as a company has installed its own generation system, e.g., in the form of photovoltaics, it should consider energy management as a next step. If storage systems and controllable loads are also in the mix – for example together as a bidirectional charging point – energy flows can be controlled in a targeted manner.

How important is integrated control technology such as PC-based control when it comes to controlling both the building and production operations, and coordinating them in terms of energy?

Dr. Fabian Assion: An integrated Beckhoff solution makes it very easy to determine comprehensive energy data. Together with a corresponding energy management system, these form the basis for considering possible process optimizations from an energy perspective and for enabling a response to increasingly dynamic electricity prices. Both offer considerable potential for reducing energy costs. Excellent examples are the process and building automation from a single source at pharmaceuticals manufacturer Engelhard Arzneimittel and the building and production automation connected via PC-based control at Austrian mechatronics manufacturer Pollmann International GmbH (see PC Control, issue 03/2022).

The growing proportion of renewable energies also requires the expansion of decentralized storage capacities. What control options does PC-based control offer for battery-powered storage systems, biogas power plants, or hydrogen storage systems?

Dr. Fabian Assion: The application areas for our control and measurement technology are as diverse as the storage systems themselves. In the battery-powered sector, an example with huge future potential is the use of electric vehicles as energy storage systems in parking garages. With TwinCAT 3 IoT OCPP (Open Charge Point Protocol) and the EL6761 EtherCAT Terminal, Beckhoff offers a complete solution for ISO 15118 communication between charging stations and electric vehicles, between existing charging points, and between charging points and/or the associated central management systems. Reverion’s biogas power plants in a compact container design (see PC Control, issue 01/2024) and GKN Hydrogen’s low-pressure, metal hydride hydrogen storage systems (see cover story of this PC Control issue) demonstrate how PC-based control can be used to implement flexible process control and seamless data monitoring for other storage technologies.

Is there anything else you would like to add as a final point?

Dr. Fabian Assion: We are all facing a variety of major challenges and one of them is the restructuring of our energy supply. Beckhoff is doing all it can to stay true to our owner and company founder’s motto which is “Engineers must save the world!”. But it’s fair to say that we can’t do this all on our own. So I would like to offer all our existing and future customers the opportunity to help us tackle this task together!