PC-based control automates container handling for 3D printing processes

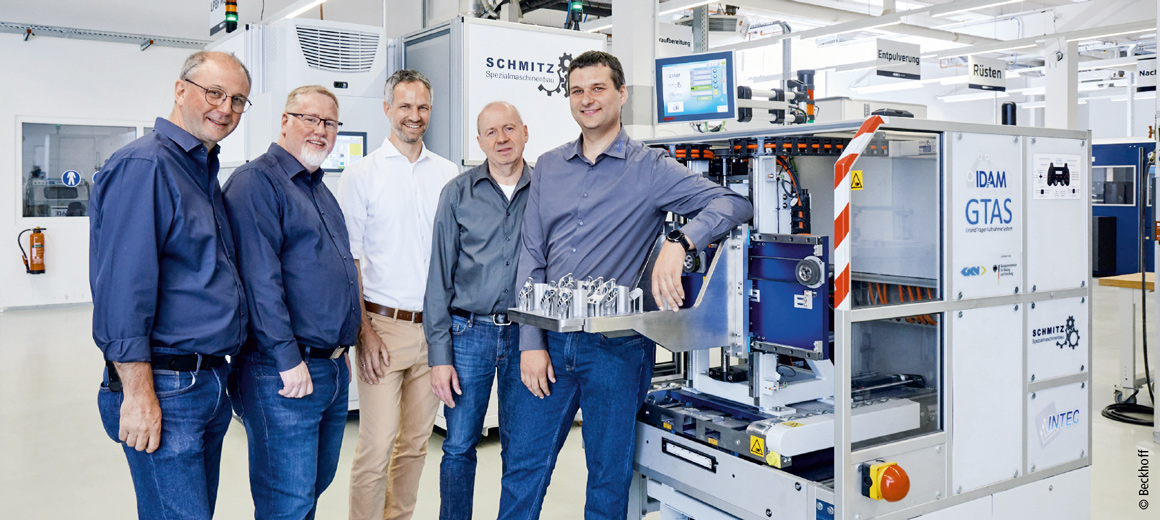

The aim of the BMBF-funded IDAM project is to make it possible to use additive manufacturing for the series production of automotive parts. Its central component, the base carrier support system (BCSS), was automated by the companies Intec and Schmitz Spezialmaschinenbau with PC-based control from Beckhoff. The BCSS has enabled automotive supplier GKN Additive in Bonn to link together various production steps to create a fully automated pilot system for 3D printing metals.

Additive technologies such as the LPBF process (laser powder bed fusion) are already being used in series applications, but only as individual processing stations. One of the reasons for this is that the working area of the machines must be hermetically sealed. This is due to the metal powders used in additive manufacturing, which are extremely fine and therefore “respirable”. For this reason, the metal powders and components are fed in and out in closed containers and this is predominantly done manually. “Our base carrier support system solves this problem and enables a fully automated process chain,” says Dr. Simon Höges, who is responsible for the Technology and Industrialization division at GKN Additive, highlighting the potential of the research project.

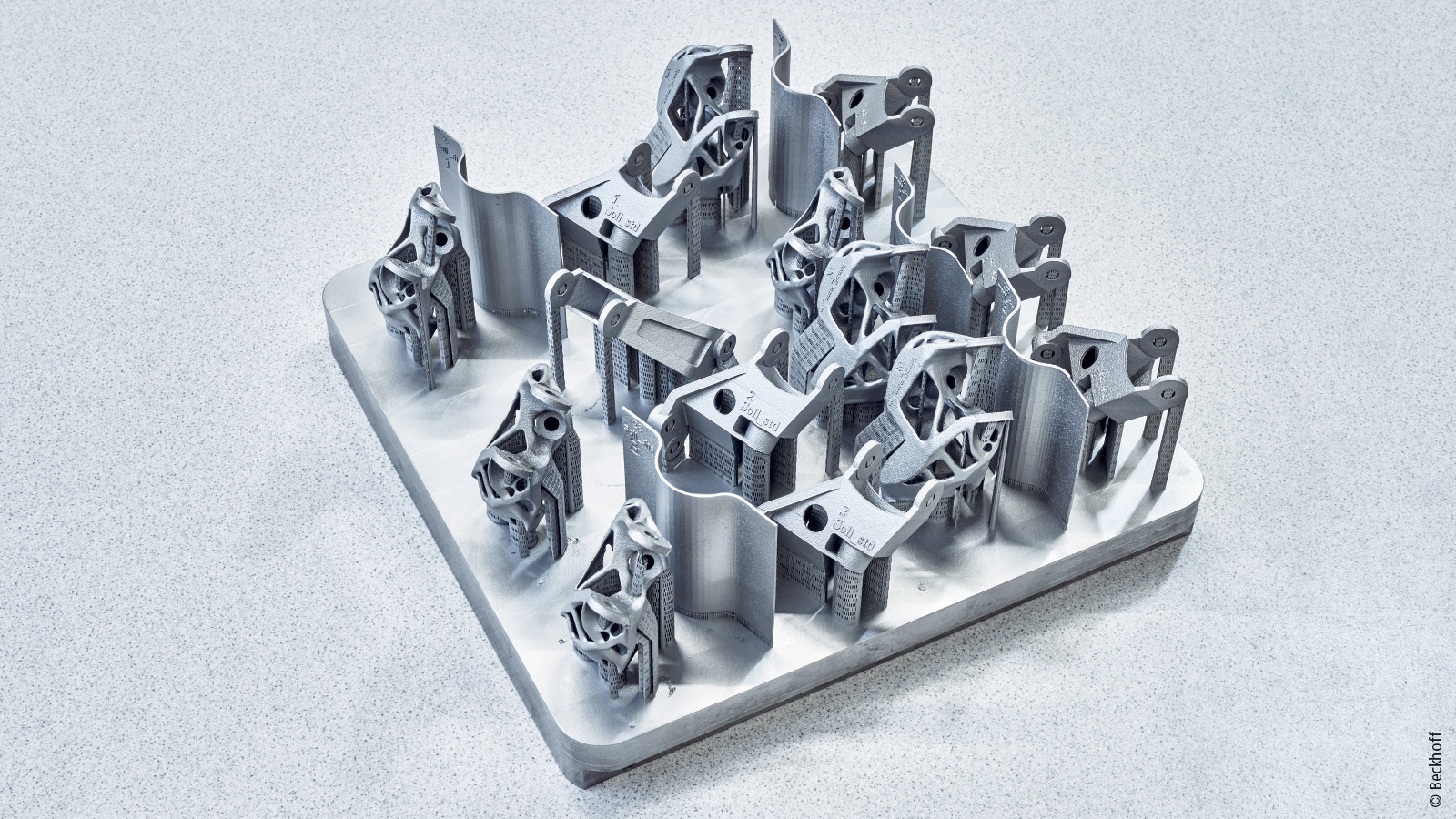

The company has been producing series parts for the automotive industry using additive manufacturing such as LPBF for some time now. In this process, metal powder is melted layer by layer with a laser at the exact point where the component structure is to be created. The advantages here are that no specialized tools are required and new designs can be implemented flexibly. “This is why we are working hard on scaling up the production processes to series production,” says Dr. Simon Höges.

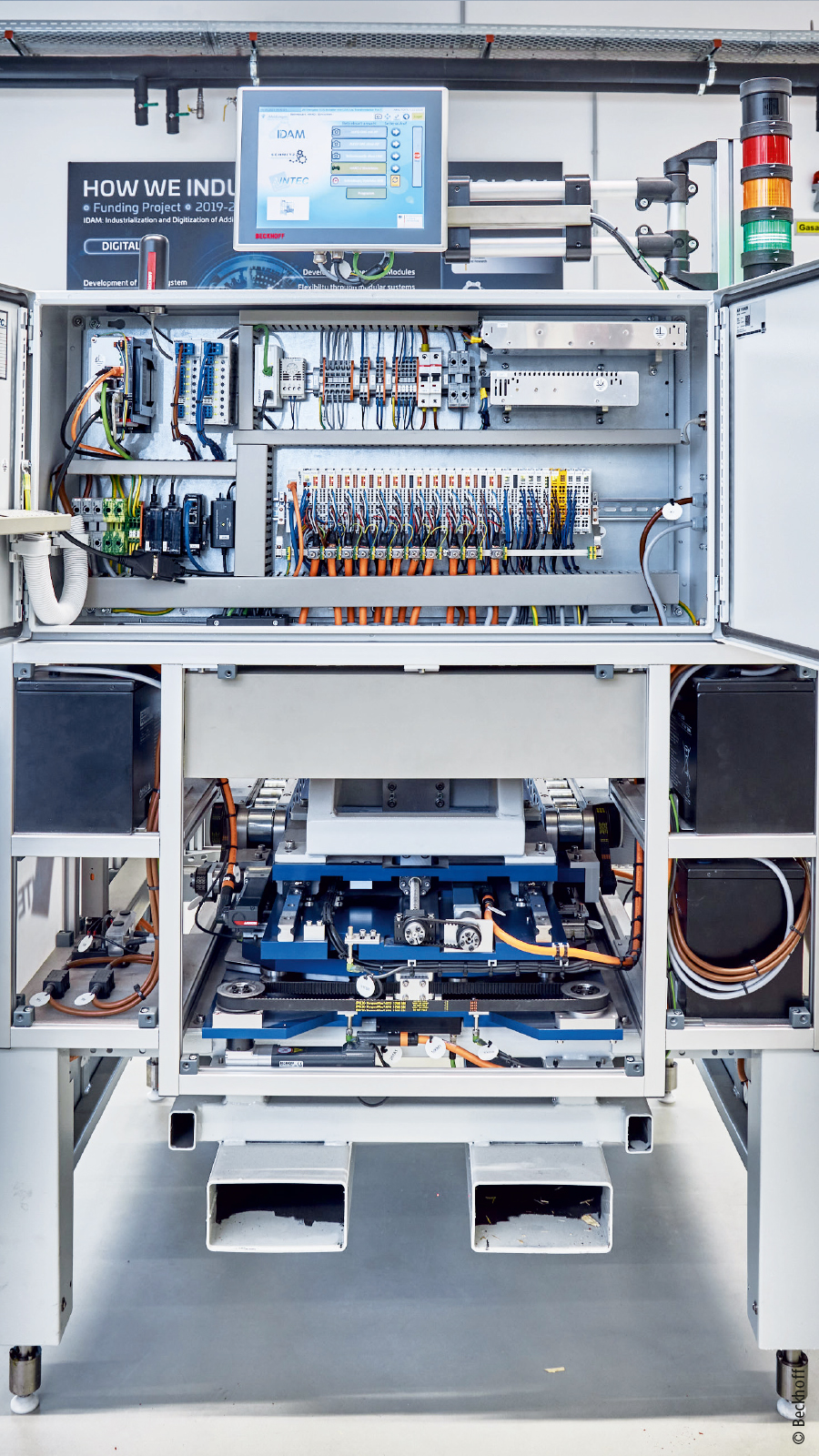

“The BCSS is the missing link for the industrialization of additive manufacturing, especially with regard to the modularity and utilization of the processes,” emphasizes Reinhard Schmitz, Managing Director of Schmitz Spezialmaschinenbau. The BCSS connects the individual process steps and machines (3D printer, powder handling, and post-processing) to form an automated overall system. “Using many different manufacturers inevitably leads to different mechanical and electrical interfaces,” says Reinhard Schmitz, explaining the challenge for the mechanical design and automation of the BCSS. For example, the base carrier support system must be able to move cylindrical containers and carrier plates with a diameter of 330 mm as well as rectangular carrier plates and containers weighing up to 750 kg safely and precisely. The BCSS has a total weight of 1,500 kg and dimensions of 1,200 x 800 mm with a maximum height of 1,800 mm so that it can be combined with automated guided vehicles (AGVs) from as many suppliers as possible and can be moved to a wide variety of system modules.

Compact drive technology saves valuable installation space

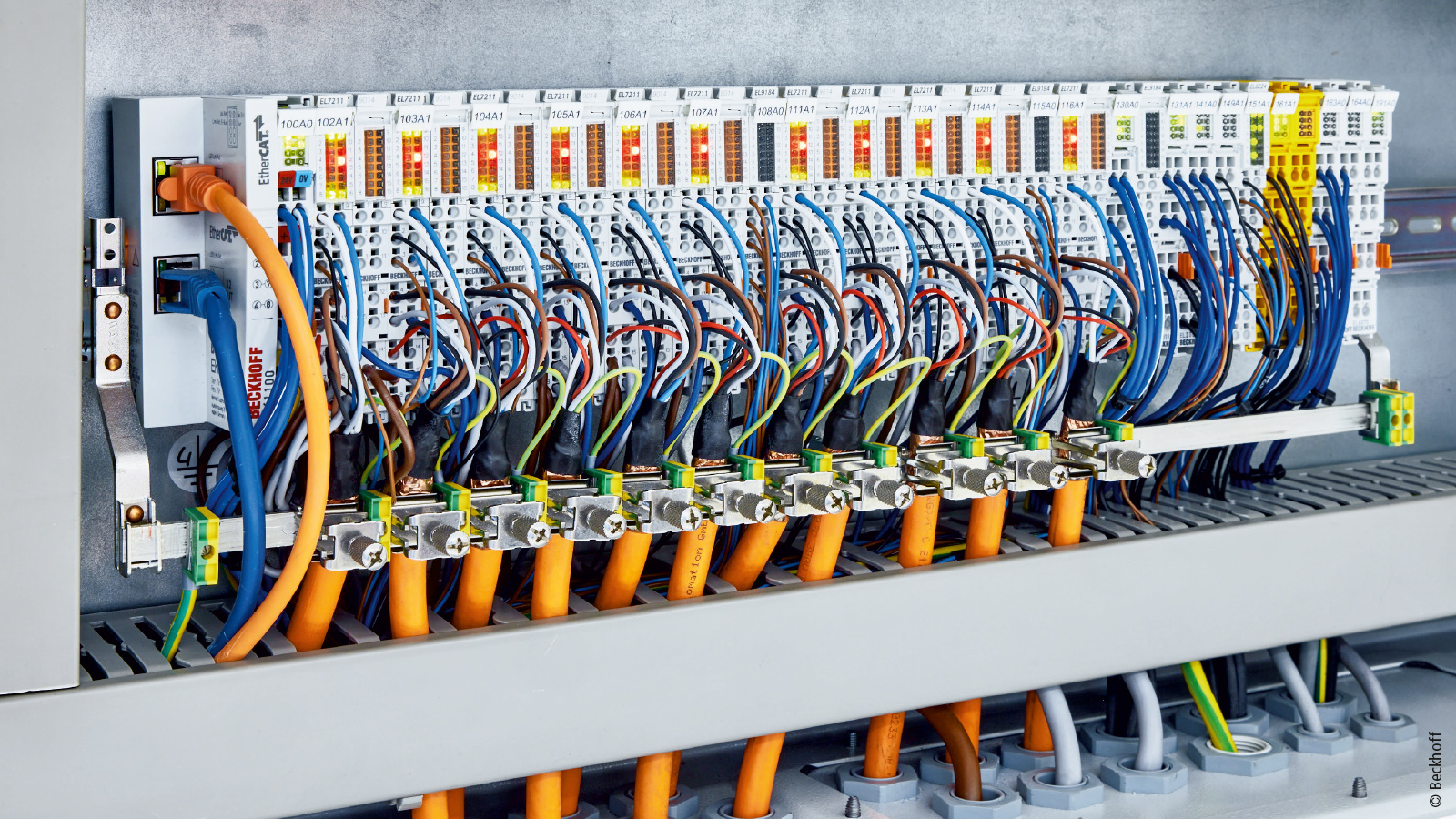

These requirements had a massive impact on the space available for the control cabinet and the components used. “The control technology had to be as small, light, and powerful as possible and function without air conditioning despite its high performance,” emphasizes Achim Heimermann, Managing Director of Intec, Ingenieurbüro für Automatisierungstechnik. The high-performance computer, six axes for positioning the BCSS, five axes for the transfer/takeover functions, and the I/Os for the various sensors had to be integrated in a very small space, including compact AM8112 synchronous servomotors and EL7211 servomotor EtherCAT Terminals with STO, as well as an ultra-compact C6030 Industrial PC. “With the industrial PC, the compact servomotor terminals, and One Cable Technology (OCT) as the connection technology, Intec was able to save a lot of space,” says Wilm Schadach, head of the Beckhoff sales office in Monheim. “With systems from other manufacturers, we definitely wouldn’t have been able to set it up so compactly and connect it so easily,” confirms Erik Heimermann, also Managing Director at Intec.

This has created space for a total of three rechargeable batteries with a capacity of 105 Ah – enough energy to ensure self-sufficient operation of the production lines at weekends, which GKN plans to implement in the future in conjunction with AGVs. “Currently, the BCSS is roughly positioned in front of the workstations manually using an electric pallet truck,” says Dr. Simon Höges. The fully automatic process then starts, beginning with the leveling of any unevenness in the hall floor using four adjustable feet. “The Beckhoff drives with integrated safe torque monitoring are essential for alignment and positioning in front of the individual modules,” emphasizes Stefan Hornberger, project manager at Intec. The torque monitoring of the adjustable feet is used to check whether all of the feet have been placed on the floor surface after alignment via an EP3752 EtherCAT Box with two 3-axis acceleration sensors and whether the four drives are each applying the same torque diagonally. Only then can the BCSS be confirmed as horizontal and stable, which means that the gripper can now move to the specified height to start the transfer sequences for the containers and substrate plates.

Openness and flexibility of PC-based control

With the compact drive technology from Beckhoff, the BCSS compensates for position deviations in front of the modules. “The accuracy is between 0.5 and 1 mm in terms of the height offset, lateral offset, tilt offset, and angular offset,” says Reinhard Schmitz. To achieve this precision, various sensors are used. These are read in via an EL6224 IO-Link terminal, for example. Two precise laser sensors with EtherCAT connection determine the angular offset between the BCSS and the machine module. “Intec can read in the XML description of the lasers via EtherCAT and access all parameters and user data directly in TwinCAT,” says Wilm Schadach, demonstrating the openness of PC-based control. At the same time, a camera and TwinCAT Vision are used to scan a QR code on each machine module to check whether the base carrier has been placed in front of the correct module and positioned correctly. To assist the operator of the electric pallet truck, the live image from the camera is displayed on the BCSS Control Panel (CP3912). Due to the installation situation, it is also necessary to control the camera lighting with an EL2502 EtherCAT Terminal and its PWM output. “The flexibility of PC-based control in one system – diverse I/Os, high-performance and open control, visualization, compact drive technology, vision, safety, and communication – has made the implementation of all these functions much easier,” says Stefan Hornberger.

Further proof of the openness of PC-based control can be found in the integration of a wireless game controller for setting up the motion sequences: Intec reads the communication data of the game controller into the system control via .NET, TwinCAT HMI, and TwinCAT ADS. This brings the operator closer to the action. Further configuration of the container transfer is then carried out on the control panel.

In automatic mode, the transfer cycle is converted depending on the distance determined after positioning and the process is started. The network of various system modules and BCSS is controlled by a central monitoring unit – the digital automation level. It initiates the transfer and takeover sequences via WLAN and monitors the process sequence. This higher-level coordination of the processes takes place on a C6025 ultra-compact Industrial PC, where the production data of all modules in a line is brought together via EtherCAT, OPC UA, or HTTPS. Dr. Simon Höges: “Intec also implemented the communication with our production planning software. This enables several orders to be processed fully automatically over a weekend.”