Modular IP65 servo drive technology in a packaging machine for the food industry

From the food to personal care to the electronics industry – mid-sized companies in particular rely on factory automation to secure growth. This requires reasonably priced and robust technologies that optimally support their production targets, which is precisely why Syntegon's UK-based subsidiary brought automation specialist Beckhoff on board to expand its modular packaging solution portfolio. The aim was to develop a cartoning machine for the food industry that could be flexibly integrated into a production line anywhere without taking up floor space with bulky control cabinets.

Syntegon, a global supplier of process and packaging technology for the food and pharmaceutical industries, has designed the new end-of-line cartoner as an entry-level machine and recently equipped it with AMP8000 distributed servo drives rather than mechanical drive technology. According to Pete Hyde, electrical and software engineering manager at Syntegon, this is a key requirement for stable processes: “Switching to servo technology allows us to ideally synchronize different drive components, securing repeatable product placement. The flexibility and reliability that this achieves are key to the success of our equipment.”

According to Syntegon, changing customer and economic requirements mean that in food manufacturing, consistency wrestles with flexibility at every turn. From adapting recipes based on changing ingredients to navigating supply chain demands and limitations, flexibility in food manufacturing is the name of the game, they say. Packaging is a critical part of this procedure, especially when the packaging machine is required to load the food product into the packaging before sealing. The tolerances for variation are extremely low, so machines must be optimized for light handling of products and flexible enough to carry out multiple functions so as not to lose valuable time in the manufacturing process. While the main components of a cartoning solution are usually made to be modular anyway, traditional machines rely on extensive wires. These would also be connected to a control cabinet, which not only increases the machine footprint significantly, but also decrease the flexibility within the production facility.

Control cabinet-free drive technology implemented in close collaboration

Syntegon was able to count on Beckhoff’s comprehensive expertise and dedication in the field of automation and drive technology without cabinets to surpass all of its expectations for a new carton erector in the form of the Basic End-Load Cartoner (BEC). But the successful partnership between Syntegon and Beckhoff goes further back than developing this modular machine together. Indeed, the two companies were already global technology partners, and Beckhoff works closely with Kliklok – part of the Syntegon Group – in the UK. The Kliklok ACE Topload Carton Former, for example, also involved beta testing of some of the latest Beckhoff technologies, including the AMP8000 distributed servo drives. Pete Hyde explains, “Because Syntegon were beta testing the components, there were many changes required to accommodate continuous improvement. It was obviously being developed and designed to our needs as we were testing it. We agreed that we would be a beta tester, so we knew there would be challenges along the way. When we hit problems we would liaise with the Beckhoff team in Germany as well as the UK. We would have regular meetings between both Beckhoff sites, and the team would make changes that we wanted to be implemented; any updates would also be done, and they would be done quickly.”

Both the test results and feedback from ACE end users confirmed the success of the collaboration, which is why Syntegon co-developed with Beckhoff on the BEC machine not only in terms of electronics, but also right from the ground up. The machine is a cartoner that loads the products to be packed from several in-feeds into a carton before closing and sealing it. The difference between the BEC and comparable systems is that this machine does not require control cabinets and so the cabling is much more straightforward. It also offers a plug-and-play solution for a food manufacturer’s production processes.

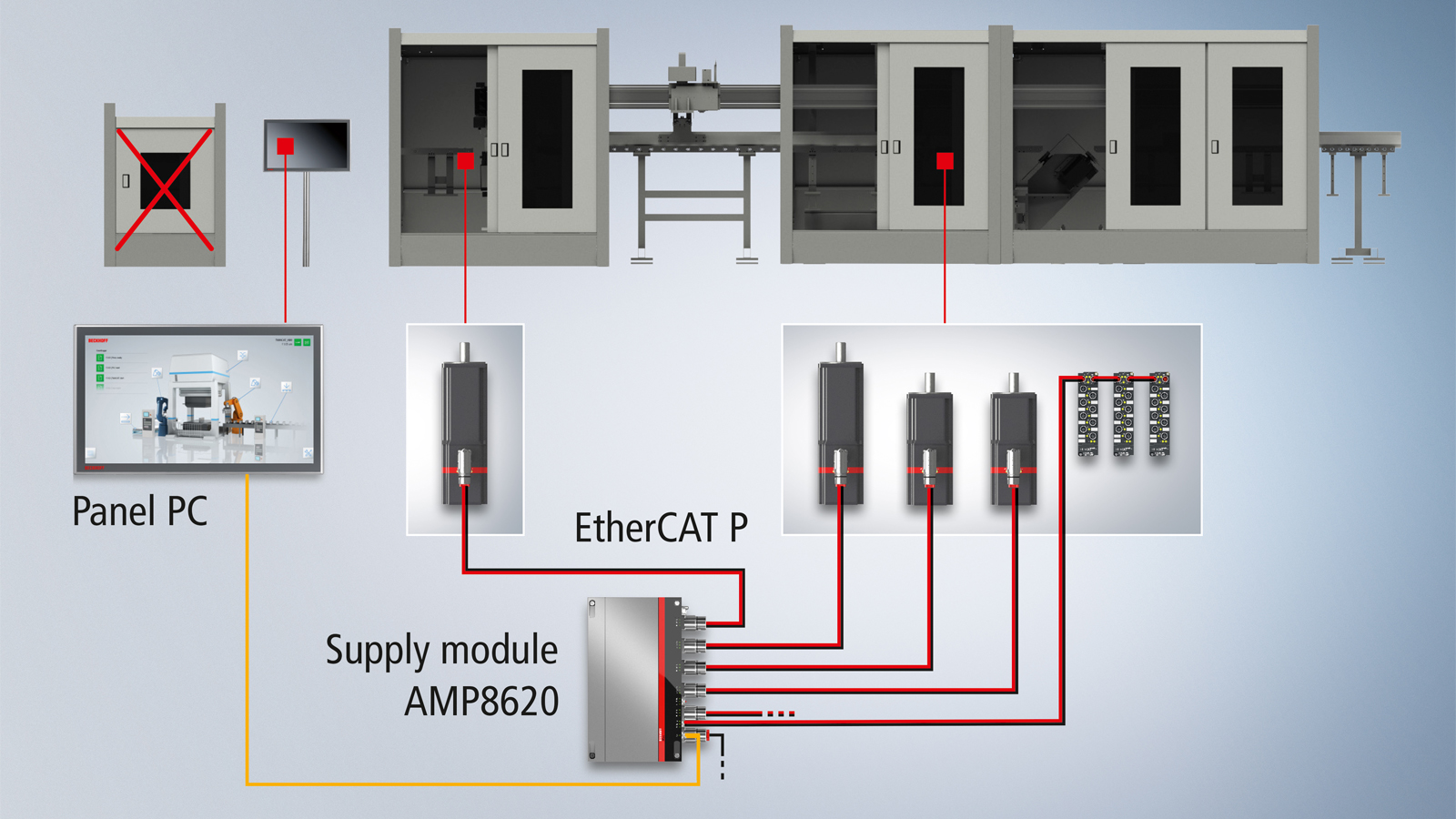

The BEC cartoner uses the AMP8000 system, which allows the servo drive to be relocated from the traditional control cabinet to the machine. The AMP8000 distributed servo drive system consists of a combination of the proven AM8000 servomotors with a highly efficient servo drive and power electronics with cold switch technology that limits power loss to unprecedentedly low levels. It also reduces the mounting space required for the electronics to a minimum. At the same time, the motor retains almost its original size; negating the need for a larger drive train and achieving almost the same performance data as a comparable motor/servo drive combination without attached power electronics.

Added flexibility with EtherCAT and TwinCAT

The EtherCAT P one-cable solution, which combines communication and power supply in a single cable, is the universal basis for the cabling of the AMP8000 distributed servo drive system. Apart from the simple connection options, the BEC cartoner generally benefits from the advantages of EtherCAT communication, as Pete Hyde explains, “With its cycle times of less than 100 µs, using XFC (eXtreme Fast Control Technology) and distributed clocks, EtherCAT realizes synchronous real-time data, aligning with Industrial Internet of Things (IIoT) strategies of modern machine architectures. EtherCAT also enables a flexible topology and a simple line or tree structure that requires no costly infrastructure components. The result is outstanding, cost-effective performance paired with highly dynamic servo drives and ease of configuration.”

TwinCAT 3 automation software from Beckhoff is also used in Syntegon’s BEC cartoner. Pete Hyde adds, “Combined with EtherCAT, it provides the fundamental technologies and tools needed to achieve Industry 4.0 concepts and IIoT connectivity – all via one PC-based control platform.” TwinCAT stores the BEC process data locally, on the server or in the cloud, always synchronized with the machine cycle. The TwinCAT IoT functions support common protocols for cloud communication, facilitating data transmission to smart devices for real-time monitoring and maintenance. The software is also quick and easy to configure and, together with a Beckhoff Industrial PC as the IoT controller, establishes a seamless connection between all components of the BEC cartoner.

“The team from Beckhoff UK visited us regularly and helped with developing the application program and with commissioning,” reports Pete Hyde. “We also had regular team meetings with Beckhoff in Germany. Beckhoff application engineer Jon Hampshire supported us on site during the commissioning period, and if we hit an issue, Jon set up a team meeting with Beckhoff in Germany at short notice, so we had a good number of Beckhoff specialists involved in the process.”

Optimizations with potential for the future

Pete Hyde mentions another optimization aspect, in that, “The development of the new machine enabled Syntegon to align the components corresponded with other machines in our portfolio, simplifying our inventory supply and supply chain processes. For the end user, the BEC provides easier maintenance by using fewer electronic components and connections, making the machine simpler and easier to integrate. The BEC is based on the OMAC PackML standard, so that it can easily be integrated into customers’ lines, and can communicate across their network to pass PackML details, efficiency reports and Smart machine data. A number of sensors have been added to detect vibration and temperature of mechanical parts which are displayed on the HMI. For ease of maintenance a full 3d model is displayed on the HMI showing all components within the machine. These will then show trends to the end-user, providing a real-time picture of how the BEC is running.” And he continued: “For example, for a bearing within the machine, we can show trends on what its temperature is and how much vibration it is generating. From that, we can detect if the bearing is at risk of failing, or whether the chain tension is too loose or too tight.”

Commenting on the joint development of the BEC cartoner, Bradley McEwan, business development manager at Beckhoff UK, explains, “The way that we co-developed control technology and software already offered a high degree of modularity; now, because of the new way the machine is wired and the decentralized drive technology, it is fully modular and can adapt to any production line. Also, by temporarily repositioning a machine module, end users can easily check which configuration works best.” This modularity also makes it easy to set up smaller production lines – for example, to run test batches of new products. This also helps demonstrate how to scale up for larger production, whilst accurately determining a time to market estimation. The new BEC machine is also to be expanded into a product range with added versions for the mid-end and high-end segments, offering even more flexibility and modularity for the food industry.