The EL5032 is used for direct connection of two encoders with EnDat® 2.2 interface. The bidirectional interface enables automatic readout of position values, diagnostic data as well as internal and external temperature values and the electronic nameplate of the encoder. In addition, the EL5032 provides an encoder supply of 5 V or optionally 9 V. Extensive functions enable a cost-effective and shortened commissioning.

Special features:

- automatic reading of the electronic type plate

- saving of user-defined data in the encoder

- position value output with up to 48 bits (depending on the encoder resolution)

- integrated speed calculation

- integrated sensor supply

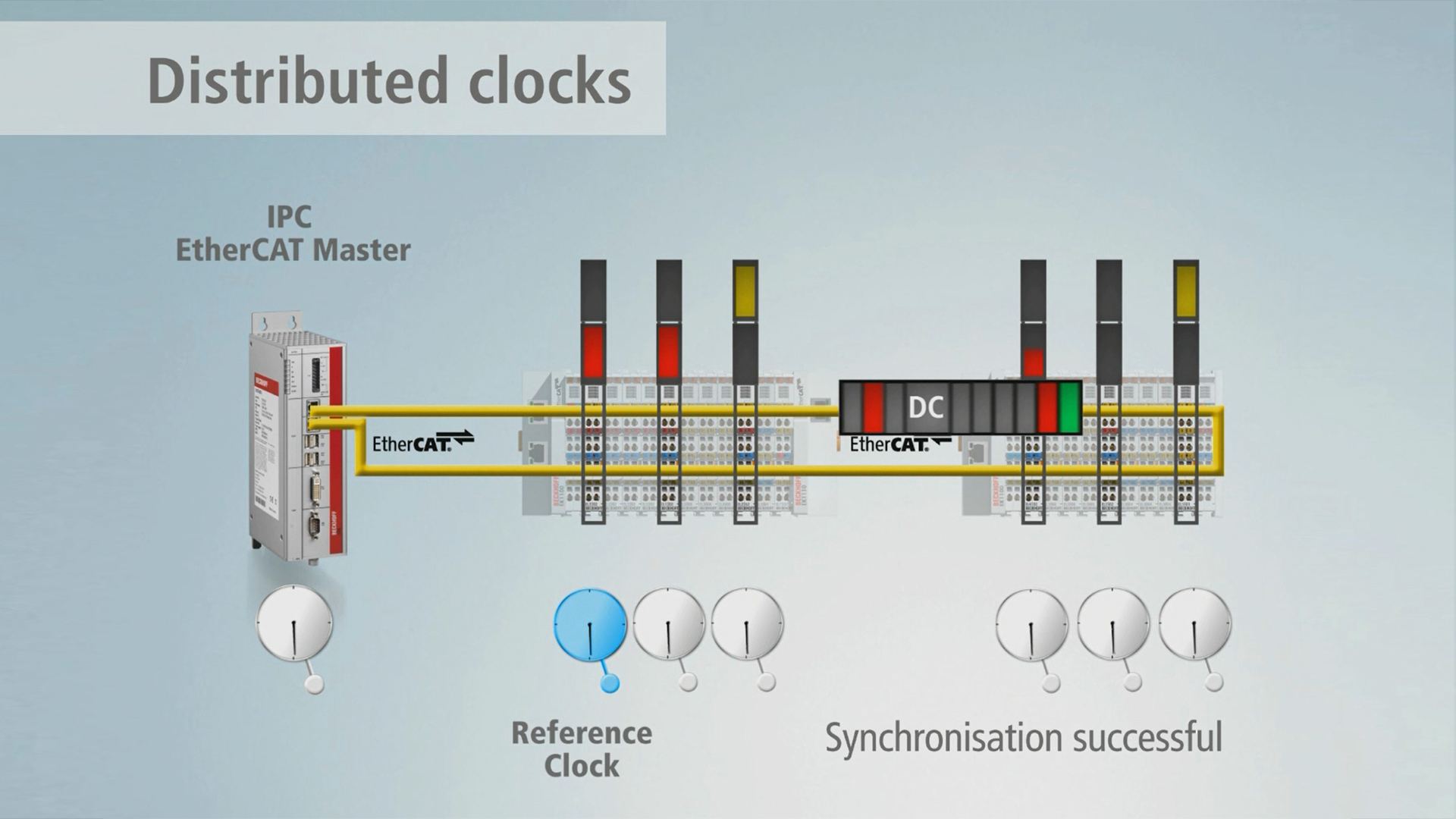

Via the distributed clocks function, the position value is read out exactly synchronously with other processes. If the distributed clocks function is deactivated, the EL5032 clocks synchronize with the EtherCAT cycle.

The use of encoder profiles enables simple and fast linking of process data for motion control applications.

Product status:

regular delivery

Product information

| Technical data | EL5032 |

|---|---|

| Technology | EnDat 2.2® interface (order designation EnDat22) |

| Number of channels | 2 |

| Encoder connection | D+, D-, C+, C- |

| Encoder operating voltage | optionally 5 V DC or 9 V DC, 0.5 A total current (generated from the 24 V DC power contacts) |

| Supply voltage electronics | 24 V DC (via power contacts) |

| Commands | reading position values including additional information available for selection via MRS code (Memory Range Select), reading and writing parameters, reset functions |

| Distributed clocks | yes |

| Resolution | max. 48 bit position |

| Current consumption power contacts | typ. 150 mA + load |

| Current consumption E-bus | typ. 120 mA |

| Electrical isolation | 500 V (E-bus/field potential) |

| Special features | saving the zero offset shift, electronic type plate, diagnostics, warning, including cable length compensation up to 100 m, reading the encoder temperature values, integrated speed calculation |

| Weight | approx. 50 g |

| Operating/storage temperature | 0…+55°C/-25…+85°C |

| Relative humidity | 95%, no condensation |

| Vibration/shock resistance | conforms to EN 60068-2-6/EN 60068-2-27 |

| EMC immunity/emission | conforms to EN 61000-6-2/EN 61000-6-4 |

| Protect. rating/installation pos. | IP20/variable |

| Approvals/markings | CE, UL |

| Housing data | EL-12-16pin |

|---|---|

| Design form | HD (High Density) housing with signal LEDs |

| Material | polycarbonate |

| Dimensions (W x H x D) | 12 mm x 100 mm x 68 mm |

| Installation | on 35 mm DIN rail, conforming to EN 60715 with lock |

| Side by side mounting by means of | double slot and key connection |

| Marking | labeling of the BZxxx series |

| Wiring | solid conductors (s): direct plug-in technique; fine-stranded conductors (st) and ferrule (f): spring actuation by screwdriver |

| Connection cross-section | s*: 0.08…1.5 mm², st*: 0.25…1.5 mm², f*: 0.14…0.75 mm² |

| Connection cross-section AWG | s*: AWG28…16, st*: AWG22…16, f*: AWG26…19 |

| Stripping length | 8…9 mm |

| Current load power contacts | Imax: 10 A |

*s: solid wire; st: stranded wire; f: with ferrule

Loading content ...

Loading content ...

Loading content ...

Loading content ...

© Beckhoff Automation 2024 - Terms of Use