Non-destructive inspection in the aerospace industry

When Innerspec Technologies was commissioned by a major aerospace end user to develop a non-destructive testing (NDT) system, the company opted for flexible automation with PC-based control from Beckhoff. The open control, motion and networking technologies of the robotic solution facilitate the inspection of a wide variety of part geometries combined with a greatly increased throughput.

Designing non-destructive test (NDT) systems for aerospace clients can be a challenge. Even when the parts under test aren’t confidential, they can change rapidly as companies optimize their designs. “The type of inspection is dictated by part geometry, material composition and the defects it needs to find,” says Cory Grant, Director of Systems Engineering at Innerspec. “We may receive a small volume of samples for the acceptance test, but we have to design machines for the huge variety of parts we’ll never see. So we work around the unknown parameters and make the machine as universal as possible.”

Innerspec has maintained its reputation as a pioneer in NDT systems since its founding in 1989. Based in Forest, Virginia, the company’s engineers design custom systems for major players in aerospace, transportation, energy and beyond. They also developed testing technologies such as Electromagnetic Acoustic Transducer (EMAT), which doesn’t require liquid ultrasonic couplant. The company supports numerous inspection types, such as Ultrasonic Testing (UT), Eddy Current and Phased Array Ultrasonic Transduction (PAUT) to meet different customer requirements.

To accommodate the expected variety of parts and test methods, Innerspec relied on the flexibility of the open, scalable technology from Beckhoff. “The Beckhoff approach to automation technology resonates with us,” Cory Grant says. “They give you open, flexible tools with solid documentation and let you mold the products to fit your application.”

Thorough testing of mission-critical components

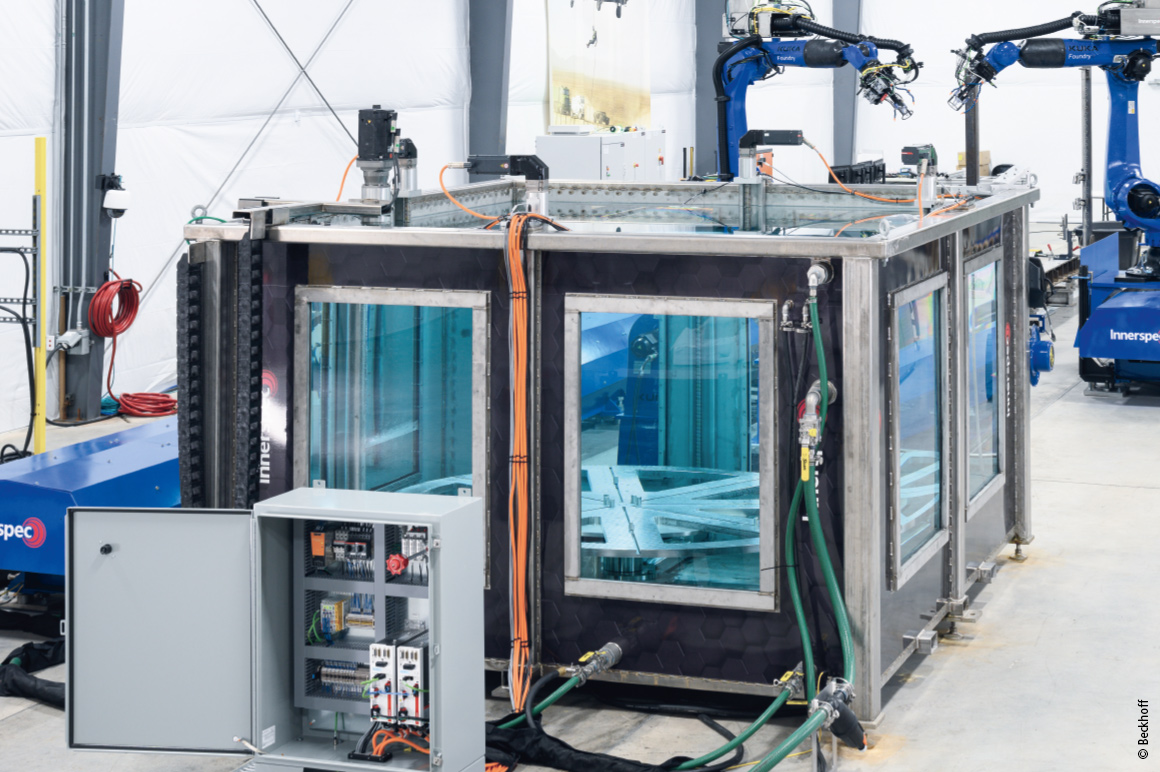

The Robotic Twin system developed by Innerspec includes a total of 18 coordinated axes of motion and includes two robots mounted on tracks, a turntable for Eddy Current inspections, a linear rotator and a 5,000-gallon (approximately 19,000 l) tank for ultrasonic testing with an immersed turntable capable of handling components weighing up to 3,000 pounds (1,360 kg).

In this system, the automation components need to share test data seamlessly with an industrial server and two third-party PCs – one for acquiring and safely storing data, another for manual analysis by a trained specialist.

Cory Grant’s first experience in building NDT systems was with a systems integrator. There, he saw how EtherCAT and PC-based control technology from Beckhoff provided an incredibly powerful and flexible platform for test and measurement applications. After joining Innerspec in 2021, he worked with the in-house engineering team to begin migrating to Beckhoff. “Even back in 2015, I started searching for control systems that were more flexible and incorporated software development principles, version control, Structured Text and object-oriented programming. Working with Beckhoff continues to be a major advantage in these areas,” Grant says.

Automation software promotes development

According to the Innerspec experts, the key to enhancing the NDT system’s capabilities and flexibility was the Beckhoff Software TwinCAT. Beyond streamlining PLC and PTP motion control, the software provides an end-to-end engineering and runtime environment for all aspects of automation. “TwinCAT is integrated into Microsoft Visual Studio, so it empowers our engineers to program in the languages that best fit the application,” says Beckhoff Sales Engineer Rodney Reid. “These include IEC 61131-3 languages with their object-oriented extensions, predefined or custom function blocks, and computer science standards from C# and C++ to Python.” Cory Grant took advantage of this to facilitate collaboration between the controls and software engineers. Together, they built the machine’s operator interface in TwinCAT HMI, which supports modern UX creation using web-design standards like HTML5 and JavaScript.

Innerspec’s system also benefited from the TwinCAT XML Server. This function provides a PLC library that enables write/read access for XML data that is stored in the PLC as a variable. “In this way, I can add all the configuration settings to the XML file. So whether the customer is setting up for a new part or conducting maintenance, the TwinCAT XML Server increases extensibility, transparency and control,” explains Cory Grant.

Central control of the aerospace test center

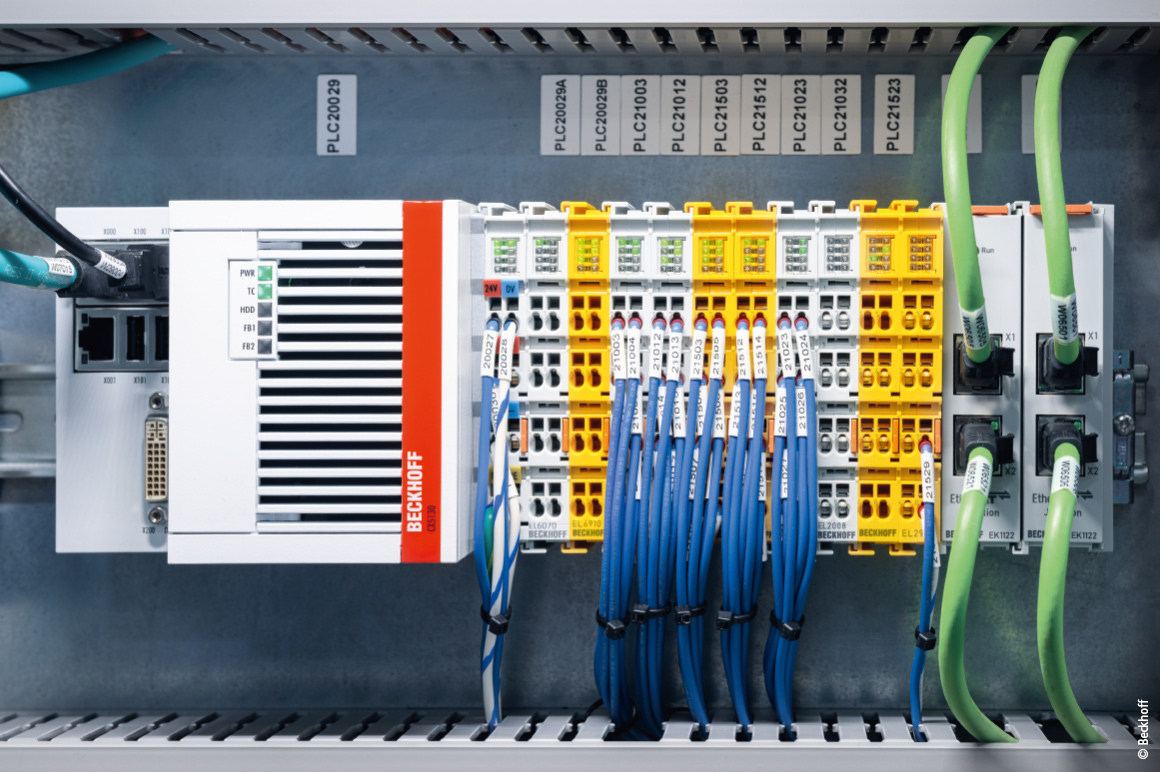

A Beckhoff CX5130 Embedded PC serves as the machine controller for the entire system. Via directly connected EtherCAT Terminals, the CX5130 acquires data from various sensors on end-of-arm tooling and sends it to the system’s server and analysis PCs using OPC UA and MQTT functionality in TwinCAT IoT. The multi-core machine controller’s fast cycle times support precision motion for the four servo axes realized with AM8000 servomotors and AX5206 Servo Drives as well as for 16 third-party motors and two robot controllers.

The result is a powerful system that enables submerged inspection of parts measuring up to 100 inches or 250 cm in diameter and weighing 2,500 pounds, equalling more than a ton. “As the turntable raises and lowers, TwinCAT libraries for software-based gearing perfectly sync the motors,” Cory Grant says. “When the turntable nears the bottom of the tank, the servo system switches from a position-based mode to a torque-based mode. By turning the motors to a specific torque, we push the frame into the floor of the tank up against wedge hard stops, which lock it in place. That way, giant parts remain stable even when they’re spinning at 30 rpm.”

Two dual-channel AX5206 Servo Drives power all four Beckhoff motors. They also directly integrate functional safety in the drive components via TwinSAFE. Using Safety over EtherCAT (FSoE) communication, the safety-relevant drive functions STO, SS1 and SS2 are supported. .

The real-time communication with EtherCAT enables precise synchronization among the motion axes. In addition, combining power and communication via One Cable Technology (OCT) helped to reduce wiring time and costs on the 120 foot or approximately 36 m long system. “Native support for EtherCAT also removed any communication barriers with the robots and made it easier to swap our end-of-arm tooling on the fly. Here, EtherCAT’s Hot Connect capabilities help us accommodate different inspection types,” says Project Engineer Joseph Ziedas from Innerspec.

Performance boost through seamless integration

Innerspec met all of the highly demanding technical requirements for their major aerospace customer. The Twin Robotic NDT System retains peak flexibility to accommodate new parts or processes in the future. The transition to Beckhoff technologies helped ensure greater performance. For example, Cory Grant can write custom C++ code and deploy it via a TwinCAT function rather than use the robot controllers’ base functionality for triggering tools: “With KUKA’s Fast Send Driver, you can go down to 1 ms per update, but with our software algorithms implemented in the C++ module in TwinCAT, we can do it in about 100 µs. So we can basically trigger instruments 10 times faster than we were able to previously, which dramatically increases inspection speeds and accuracy.”

The PC-based control technology from Beckhoff also enhanced operator interaction through TwinCAT HMI – with a built-in view of the EtherCAT diagnostics – and TwinCAT XML Server, Cory Grant explains: “My goals when building systems are, one, to make the machine operators happy and, two, to make the maintenance personnel happy. On the Robotic Twin, we know the operators love the look, feel and interface on the machine, along with its reliable performance and flexibility.”