Continuously recording energy data in the grid lays the foundations for greater efficiency in machine and system operation. System-integrated energy monitoring makes it possible to improve not only energy efficiency, but also availability. This is because valuable status information for predictive maintenance can be derived from the energy readings in the machine environment. For example, if a machine starts to increase its power consumption, this can indicate bearing wear; a decrease in power consumption can indicate quality problems in production, and a sudden drop in performance requires immediate intervention.

Recognize and tap into optimization potential:

- improved energy efficiency and reduced carbon footprint

- stable power quality through active energy management

- lower energy and operating costs

- increased productivity as a result of preventing downtime

Our product highlights for energy-efficient machinery

Distributed power measurement in the low-voltage grid

Distributed power measurement from Beckhoff offers real cost advantages, particularly in low-voltage main distribution boards and machinery with a large number of loads to be measured. The compact design makes it possible to measure up to 6 current channels in a 12 mm installation space. The associated voltage values are measured once in the system and distributed via EtherCAT. In combination with our IoT solutions, it opens up a whole new world of transparent, flexible, and cost-effective energy management.

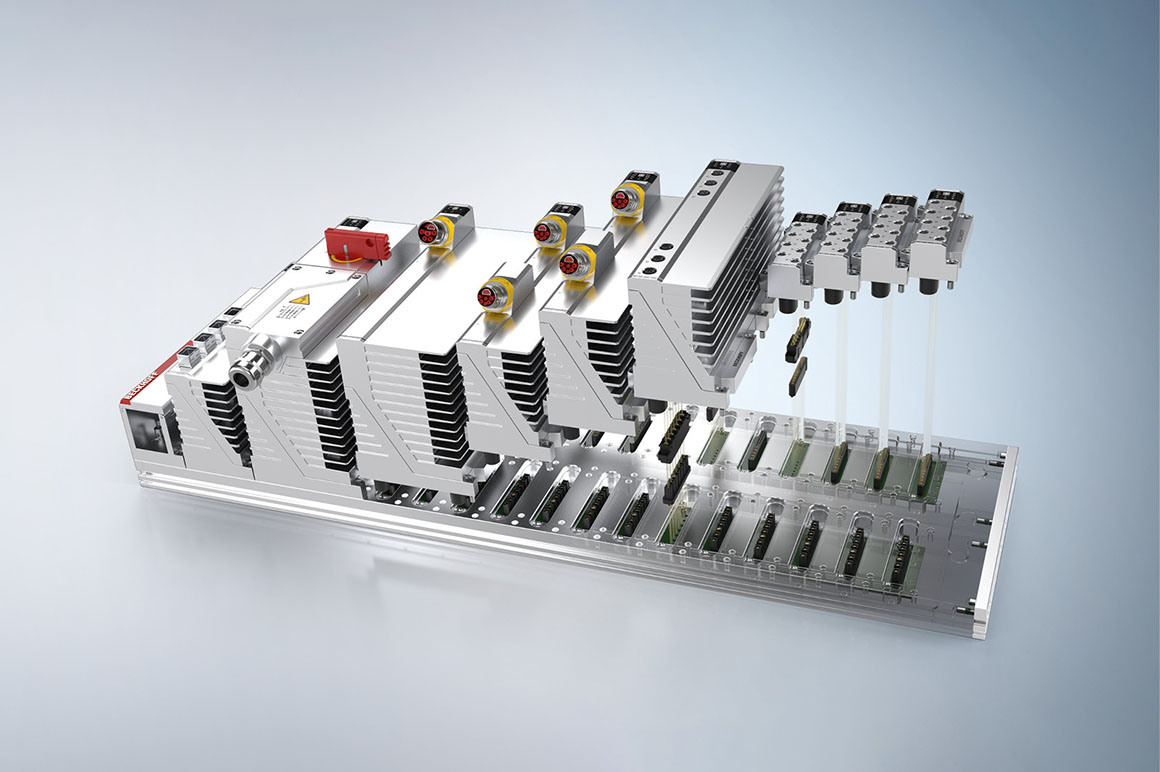

MX-System – integrated energy monitoring with EtherCAT

The modular MX-System for control cabinet-free automation relies entirely on EtherCAT. Integrated power measurement provides information on the consumption of connected components without the need to install additional measurement technology. What’s more, the fully integrated EtherCAT components facilitate rapid system diagnostics. There is no need to open up and measure any control cabinets. The plug-and-play principle makes it easy to replace modules during ongoing operation. The MX-System is also DC-ready, as the configuration for 600 V DC ensures the system can integrate seamlessly into advanced DC power supply concepts.

DC industry – efficient direct current supply for your system

The ZVEI DC-INDUSTRIE research project promotes the development of direct current networks for industrial energy supply. This facilitates the integration of renewable energy from solar and storage systems and helps to save resources. Beckhoff offers its PS9700 DC/DC converters, for example, to ensure an optimum power supply. These transform DC voltages up to a maximum of 750 V into an electrically isolated output voltage of 24 V and refresh the voltage in extended networks. They also compensate for the fluctuating output voltage of battery systems.

Grid-compatible feedback of regenerative braking energy

The AX8820 universal regenerative unit from Beckhoff is used to feed regenerative energy back into the grid. It is suitable for use with servo drives from Beckhoff as well as third-party systems. Recovered braking energy is initially stored in the DC link. The device only starts feeding sinusoidal voltage back into the supply network just before reaching the overvoltage threshold. Analysis with EtherCAT also makes it possible to increase efficiency – for example, by staggering the machine processes.

Sustainable automation for the smart factory with energy management according to ISO 50001

A growing number of companies will be obligated to report on sustainability in the future. They will be expected to account for the extent to which they are cutting down on energy and material consumption and reducing harmful emissions, how high the proportion of renewable energies is, and their economic performance relative to their energy consumption. As a transformation pioneer in the German economy, Beckhoff was awarded the German Sustainability Award in the ‘transformative measurement and control technology’ category in 2024.

Choose Beckhoff to take a closer look at the energy consumption in your production processes. Use system-integrated measurement technology to record all data points and transfer them to the control system, an energy management system, and other higher-level systems. Our portfolio enables you to provide documentation in accordance with ISO 50001. By integrating this technology into your automation processes, you can count on real-time data transparency for prompt resolution of current issues and energy efficiency optimizations in the long term. This not only improves sustainability, but also the competitive edge of your company through cost-conscious load management.

Current applications

Generating sustainable growth with PC-based control

In terms of action already taken, Beckhoff implemented a successful energy management system in 2016 and was certified by TÜV Süd in line with ISO 50001 standards in the same year. The energy management system helps to steadily reduce the company’s costs and energy consumption by continuously recording all relevant consumption. Analyzing this information reveals potential for further measures to reduce energy consumption. Beckhoff thus not only demonstrates its compliance with legal requirements, but also lives up to its responsibility for climate and environmental protection. After all, less energy consumption automatically leads to a massive reduction in carbon emissions, which is set to be the major challenge for all companies going forward as we look to achieve a climate-neutral economy.

A bright future with seamless data transparency

In the global competition of the manufacturing industry, every minute of time, every gram of raw material, and every hour of kilowatt energy counts. This is a challenge that the Wienerberger Group, a leading international supplier of innovative building materials and infrastructure solutions and self-proclaimed top global brick provider, has been grappling with for decades – now with the added support of TwinCAT and Data Agent. As part of its comprehensive digitalization offensive, the Group has started sending several million measured values to the cloud every day for analysis purposes and subsequently using them in all areas of the company as a basis for targeted optimization measures.

Control cabinet-free automation as a game changer in machine and system engineering

Window and door construction is a high-tech business. This much is evident right from the first process step, with the fully automatic processing of raw bars on a profile processing machine from Schirmer Maschinen GmbH. Schirmer was founded in 1979 and was Beckhoff’s first customer. The company has been relying on PC-based control from Beckhoff for over 40 years, from the first positioning controller through to the new MX-System.

“The MX-System is changing the face of design and installation in the world of machine building,” explains Ludger Martinschledde, managing director of Schirmer Maschinen GmbH. In its initial use in a system for processing profiles, the pluggable system solution for control cabinet-free automation from Beckhoff ticked all the boxes in every project phase, from planning and design through to installation and commissioning.

150% more throughput after digital transformation at a paint factory

Pépin Industries Ltd. has been producing industrial coatings in Canada since 1958. When the company relocated to a larger plant, system integrator Centris Technologies relied on open control technology from Beckhoff to automate its traditional production processes. This technology enables end-to-end communication from the field to IT, thereby providing maximum process transparency.

Whether you are looking to measure, network, or optimize, the benefits of Beckhoff technology are widespread:

Power generation

Control and monitor power plants, wind farms, solar plants, and hydrogen production efficiently with PC-based control.

Smart grids

Ensure intelligent energy distribution with transparent monitoring of availability and demand.

Sustainable buildings

Unlock potential savings through end-to-end building automation from the office to the production hall.