XTS enables flexible bottle handling in the pharmaceutical industry

EtherCAT and PC-based control has long been used by the Marchesini Group, one of the world’s leading manufacturers of packaging machines and filling lines for the pharmaceutical and cosmetics industries. Nowadays, the Italian machine builder also benefits from Beckhoff’s XTS linear transport system. In a monoblock machine for filling and capping bottles containing tablets, capsules, or pills, XTS makes transport more flexible while reducing setup times and energy requirements.

Since it was founded 50 years ago, the Marchesini Group has always paid particular attention to the key components of its systems. This also applies to the machine software, which the company develops entirely in-house. “Unlike system integrators, our hallmark is that we are an all-round manufacturer: We develop all of our machine technology in-house and therefore know it all inside out,” explains Stefano Gualmini, head of Automation R&D at Marchesini. Fitting entirely with its concept, Marchesini’s cooperation with Beckhoff dates back to the 1990s and is based on a precise shared vision with a solid foundation.

From proprietary to open and PC-based architecture

“Since the early 1990s, we have focused our area of interest on standardized and open platforms. We wanted to move away from PLC-based control architectures,” recalls Stefano Gualmini. “This was primarily due to the availability and reliability of PC hardware and its excellent price/performance ratio.” In fact, the company implemented EtherCAT back in 2007, soon after it had been launched on the market. “We consider EtherCAT to be the backbone of our automation processes in every respect,” states Stefano Gualmini. He points out that the company’s selection criteria were – and still are – based on the platform’s open nature, efficiency, and ease of implementation. What’s more, it has been using EtherCAT to exploit the potential of functional safety via FSoE since 2013. At Marchesini, integrating safety functions on the same bus system has resulted in a huge reduction in wiring work – by some 50%. Taking this approach also optimizes the communication between the safety and standard components.

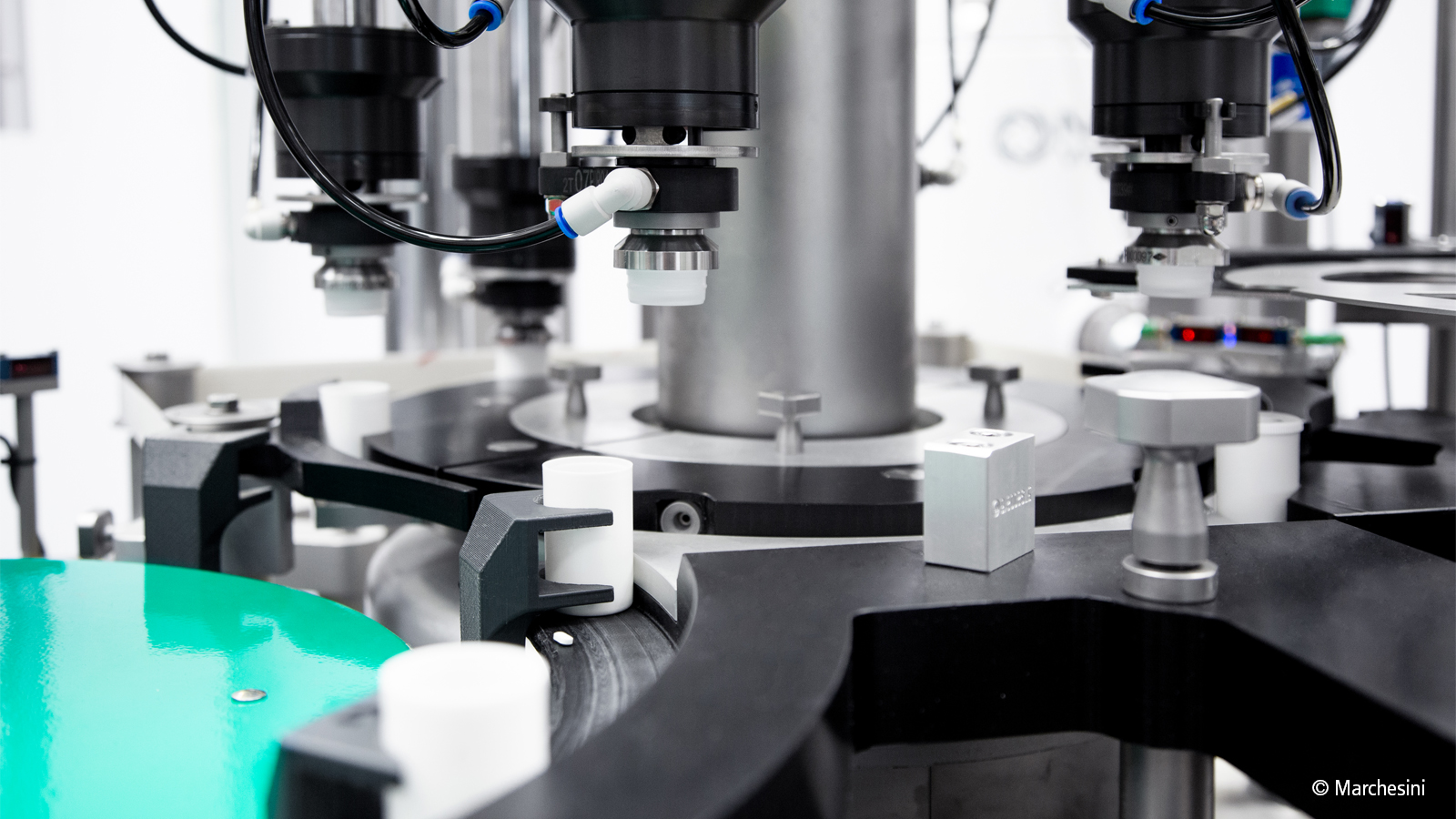

Motion control represents another core area of expertise for suppliers of packaging and filling machines. After an intensive benchmarking exercise between 2018 and 2019, the company once again decided that Beckhoff was the right choice. “We knew that we would have to take a quantum leap in terms of motion control and mechatronics to prepare for the challenges we would face in the coming years,” notes Stefano Gualmini. But the Marchesini Group didn’t just choose Beckhoff as a partner for motion applications due to their previous partnership – it was also impressed by the quality and diversity of the technologies available. Although initially classic rotary motion components were used, the XTS linear transport system now also serves as a mechatronic drive solution. One example of where it can be found is the Compact-24 monoblock machine, designed for counting solid products (tablets, capsules, pills, etc.) and adding them to bottles.

Using XTS to achieve efficient processes

The Compact-24 is a typical example of a linear machine: At the infeed, a mechanical system takes the medication bottles from a stack and places them individually on an XTS mover. The movers then move to the filling station, where hoppers appropriate for the task fill multiple bottles simultaneously with pills that have already been counted. The bottles are then transported to the next station, where they are transferred to the rotating capping unit. After that, XTS is used to move everything back to the unloading station, from which point the containers are sent on for further processing after a series of checks.

According to the Marchesini experts, the Compact-24 breaks the mold through its use of XTS for bottle transport. Each mover moves autonomously and is positioned or grouped according to the desired work sequence. With this technology, Marchesini machines now boast high linear speeds that minimize the times required for returning the empty movers to the pick-up station and for changing bottles. XTS also makes it easier to convert the format. Using the control panel, the movers can be positioned in groups and moved to defined locations for exchanging product-specific adapters.

The Compact-24 offers two special features. For one thing, the in-and-out movements of the bottles at variable intervals can be synchronized. Furthermore, the software enables the movers to be configured and adapted to the new containers and their properties when the product is changed – for example, the shape and capacity of the bottle and the distance to be maintained between the products. “XTS enables us to provide flexible and consistently optimized transport,” enthuses Stefano Gualmini. Adding pills or tablets to bottles is not quite as simple as it might seem, as these products tend to fall from the feed system hoppers into the bottles at different speeds. In addition, the filling time for each individual bottle is affected by a visual integrity check and multiple bottles are always filled in parallel. That is why each bottle must be handled individually. Compared to conventional mechanical solutions, XTS can fully exploit its strengths with the individually controllable movers in the Compact-24. The XTS technology enables each bottle to be handled individually – an unbeatable advantage when it comes to efficiency. “Given that the filling station has to count the tablets for each bottle, XTS was the ideal solution for our synchronization problems,” explains Stefano Gualmini, an automation expert.

In mechanical terms, the XTS motor modules and guide rails are fully integrated into the machine frame. From a software perspective, the movers are integrated into the automation project like normal drive axes. Several dozen axes may be involved, depending on the design, but this does not affect the application in question. “This offers considerable advantages in terms of flexibility and speed compared to conventional motion solutions,” emphasizes Stefano Gualmini.

Machine cycles increased by 25%

Measurable improvements have been achieved. By integrating XTS into its machines, Marchesini has been able to improve accuracy (with respect to tracking errors) in certain applications by up to two orders of magnitude. This has helped to increase the Compact-24 production speed from 120 to 150 bottles per minute. What’s more, using the AX8000 multi-axis servo system with its intermediate voltage circuit (DC bus) has resulted in significant energy savings of up to 20%.

“Beckhoff provides us with a constant incentive to exploit the potential that new technologies can bring in relation to efficiency and innovation. For that reason, I’m positive that our long-standing partnership will be even closer in the future,” concludes Stefano Gualmini.