Digitalization for the process industry

In the world of process automation, reliable and efficient production processes lay the foundations for economic plant operation. Modern plant concepts help to support maintenance and optimize process flows, and Beckhoff offers future-proof solutions for both existing and greenfield plants through its implementation of NOA, Ethernet-APL, and MTP. Concepts such as Industry 4.0 and the Internet of Things focus on collecting all plant operating data and making this available to various applications. This data is evaluated in analytical tools to facilitate proactive action, such as early detection of failures in field devices. It can also be used to optimize processes and increase productivity.

Plant monitoring and optimization with NOA

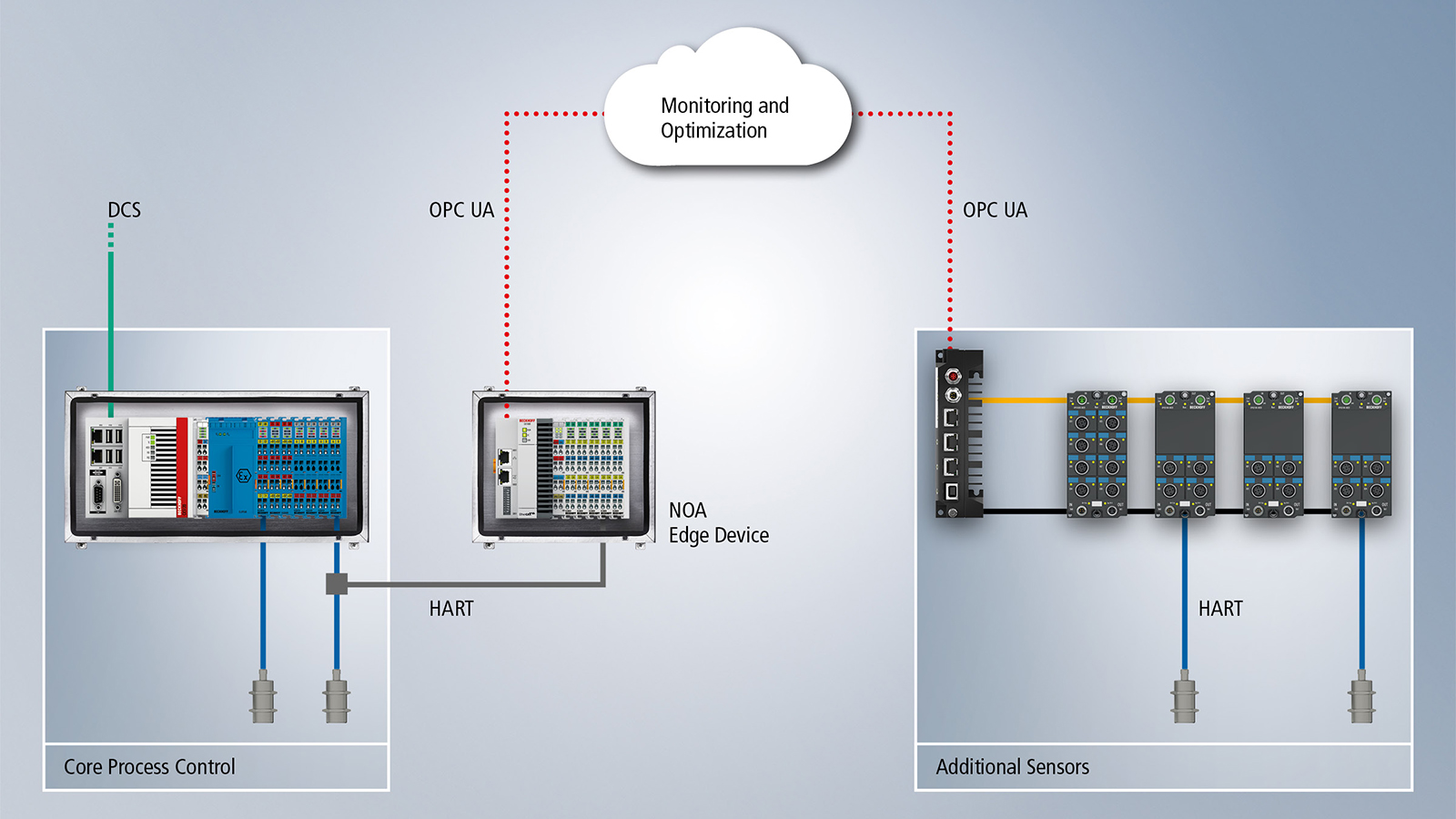

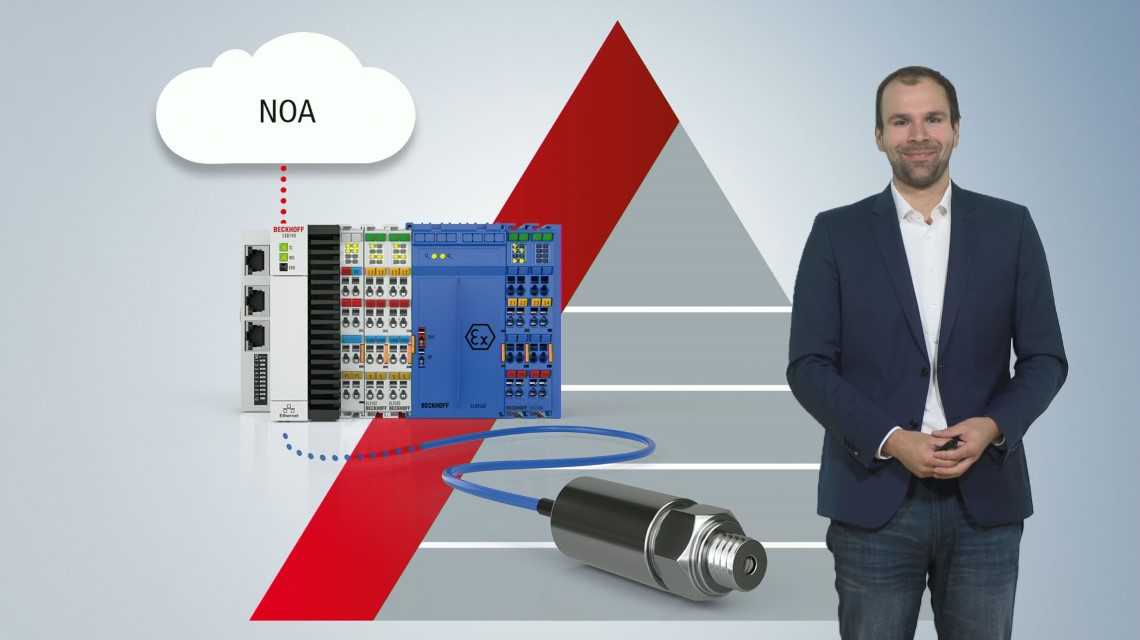

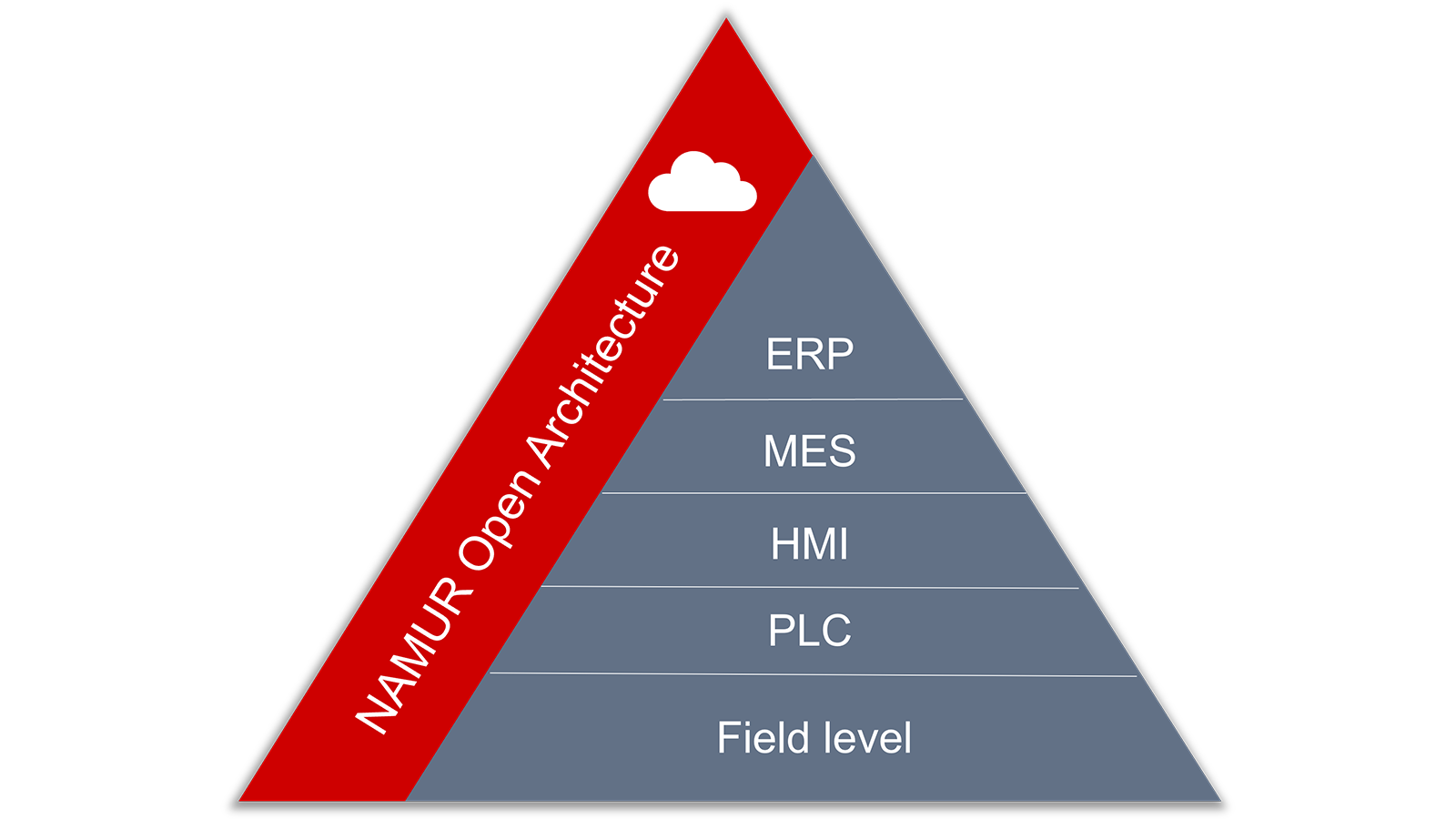

The NAMUR Open Architecture (NOA) concept described in NAMUR Recommendation NE175 extends the automation architecture without altering the existing control system. NOA's core task is therefore to provide information from the field level to higher-level applications in order to monitor the field devices and optimize the process (monitoring and optimization – M+O). The type of data that is forwarded from the field level depends on the field devices used and the respective analysis tools. The focus here is on parameters that need to be read out cyclically which contain information on device status or process quality.

Edge device for NOA

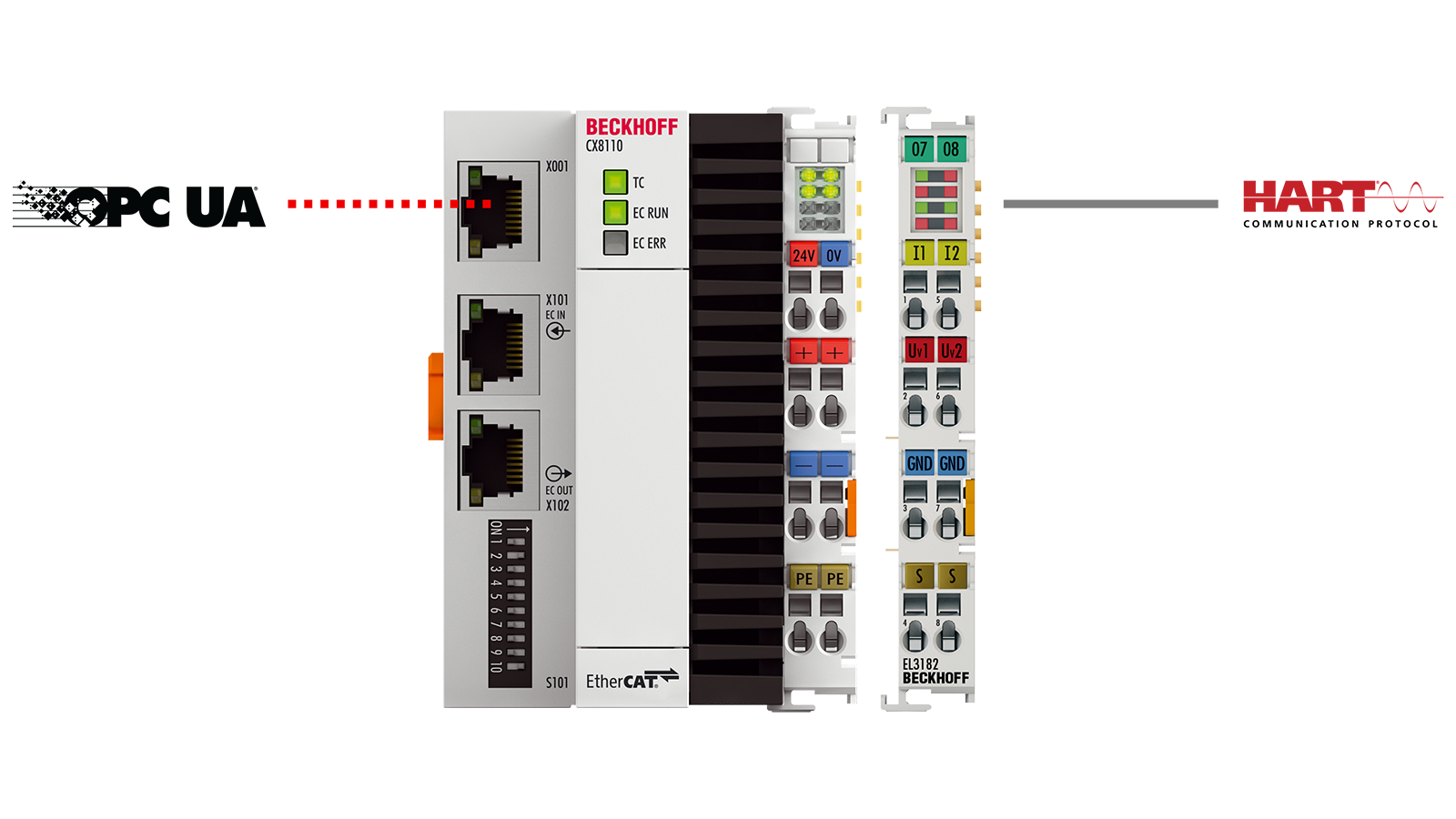

The world of process automation employs a wide range of protocols and communication technology. For the initial implementation of the NOA concept, Beckhoff opted for the HART protocol. This protocol is widely used and is implemented in many field devices from different manufacturers. Superimposing a digital signal onto the actual 4–20 mA measured value facilitates the transmission of further data, such as the field device status. Furthermore, a second channel can be opened with minimal effort with the help of special feed isolators, which already form part of the automation architecture in many plants. This means that the connection to the field device is separated into a 4–20 mA signal, HART communication, and the supply voltage, which means that the established connection to the process control system is not interrupted. The data can therefore be received via the second channel and used for M+O.

Beckhoff offers a way to connect two field devices via the HART protocol in a very compact installation space in the form of the EL3182 analog EtherCAT input terminal. Combined with an embedded PC (such as a CX8110) and the TwinCAT automation software, a modular expandable edge device can be built without any specially developed hardware.

The edge device has three main functions:

- receiving vitality data via the HART protocol

- converting and translating the data

- providing the information to higher-level analysis tools.

Commands have to be sent from the edge device so that the vitality data can be read out via the HART protocol. The data that are read out and the commands that are used to store it on the field device depend on the device type (pH, oxygen, temperature, etc.) and manufacturer. Beckhoff has developed a database to store the necessary information for reading out the vitality data. The corresponding file is read into TwinCAT, thereby facilitating communication with all field devices stored in the database. When a field device is connected to the edge device, it is automatically detected, the relevant HART commands are sent, and the received data can then be converted using the stored translation tables and TwinCAT functions.

“Ensuring that data can be accessed from all plants remains one of the biggest challenges in the world of process automation. As process plants have developed into huge networks of interconnected systems, large parts of the information from field devices are inaccessible. NAMUR Open Architecture was developed to provide a standardized interface to all information from the field, allowing data to be accessed quickly and easily. Our compact and scalable NOA edge device upgrades old systems to assure future-proof operation.” – Lennart Winkler, Process Industry Management

The vitality data that are stored in the PLC at that point must be made available for further analysis applications in the next step. NAMUR recommends using OPC UA for this. The Beckhoff portfolio offers several products, including the TwinCAT OPC UA Server. This is based on a stored information model and filled with vitality data directly from the PLC. This information model is based on the PA-DIM (Process Automation – Device Information Model), but it can also be extended with additional parameters by the user. Depending on the detected field device type, individual OPC UA nodes can be removed or added automatically.

EP series IP67-protected I/O box modules can be installed directly in the field in order to capture diagnostic data that are acquired by additional sensors, for example for vibration or temperature measurement, along with data from established field devices. Several sensors are connected to one module and the signals are transmitted to the edge device collectively via one cable. This version cuts down on cable routing work while also reducing the space required in the control cabinet.

Complete data acquisition with Ethernet-APL

The NOA concept also offers advantages for greenfield plants: additional sensors can be added during the plant planning stage, thus providing more data for monitoring and optimization. New forms of technology such as Ethernet-APL make implementation simple.

This new communication technology is based on the 10BASE-T1L Ethernet standard, which allows a maximum cable length of 1,000 meters and a transmission rate of 10 Mbit/s. Power and data are transmitted over the same pair of wires (Single Pair Ethernet) with Ethernet-APL. Power supply limits in all zones throughout the explosive atmosphere are defined by IEC specification 60079-47 (2-WISE). To simplify installation and improve the connectivity of the devices used, the project group has also defined port profiles in the TS10186 technical specification: In addition to information on the connection and segment class, a port profile also includes the Ex approval for the respective device connection.

The Ethernet-APL concept aims to implement the entire communication in process technology plants – from the field level to higher-level control systems – on an Ethernet basis. This focuses both on the pure process data and specifically on the status information of the field device. The increased transmission rate compared to fieldbus systems also allows web servers to be used for parameterization or downloading data sheets or certificates directly from the field device.

Users still face a number of challenges during implementation: APL-capable field devices are required to allow the aforementioned advantages to be exploited immediately across the board. However, as this technology is still in its early days, the market does not yet offer a broad portfolio. In established plants, there is also a lack of space for installing additional infrastructure components such as switches. Implementing Ethernet-based communication technology down to field level also requires new functions and policies for IT and OT security.

“Ethernet-APL opens up a whole world of possibilities for users. If this technology is to be implemented quickly, it is vital that it can be integrated into established installations, and the ELX6233 EtherCAT Terminal offers users the necessary flexibility, modularity, expandability, and security to achieve this." – Sebastian Böse, Process Industry Management

How can users integrate Ethernet-APL into their plants and benefit from the many advantages it offers right now? One solution is to combine the new technology with proven standards such as the HART protocol. Existing plants can thus be successively digitalized with new APL devices and the barriers to a complete conversion can be overcome.

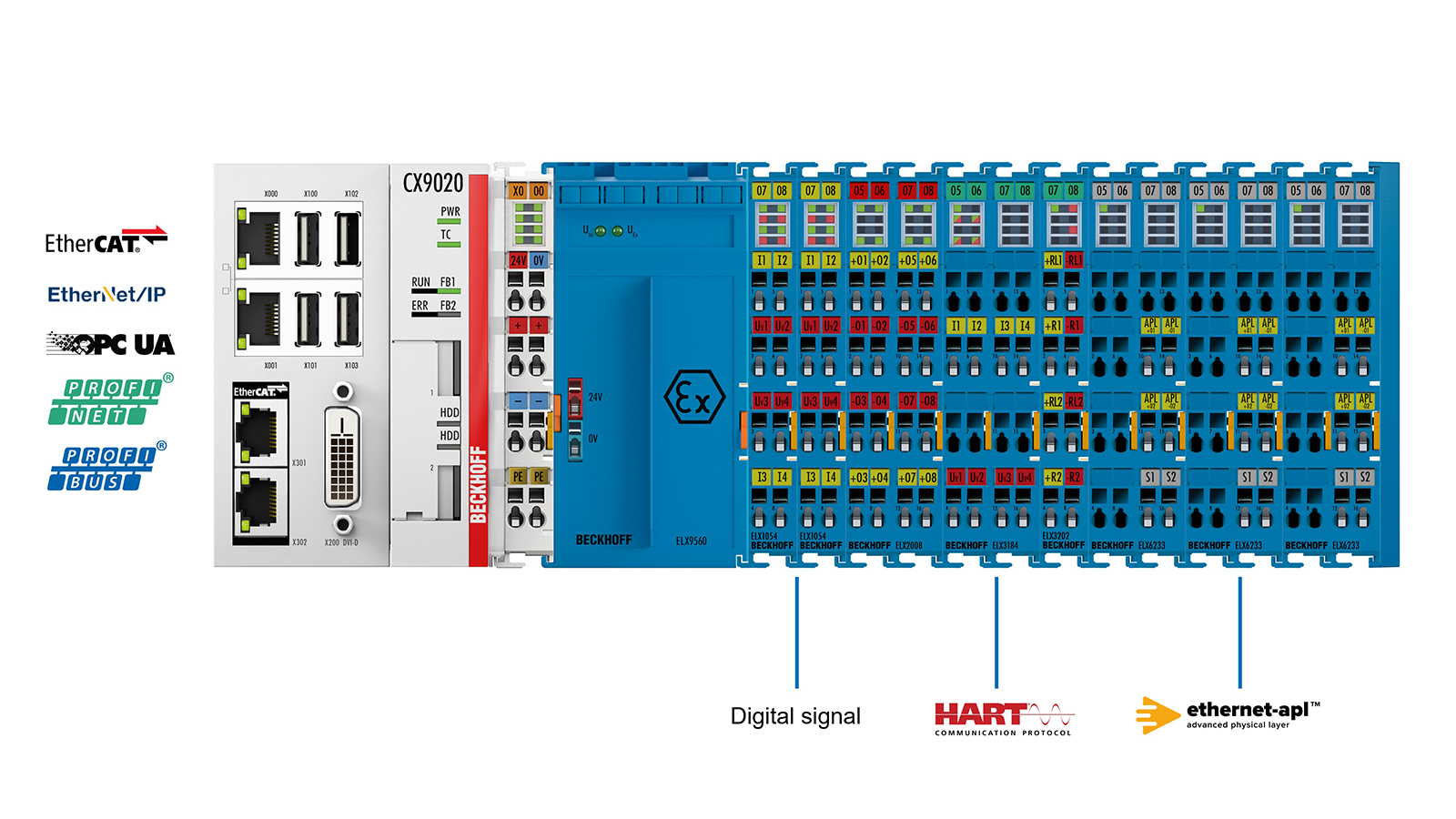

For these reasons and more, Beckhoff has already integrated Ethernet-APL technology into the modular terminal portfolio: The ELX6233 EtherCAT Terminal offers a 2-channel communication interface for Ethernet-APL. Contrary to the typical field switch concept, this creates an alternative for integrating APL field devices. The modular system allows the user to install the exact number of required Ethernet-APL channels in the control cabinet, saving valuable space and allowing the application to be expanded flexibly.

The scalability of the ELX6233 provides efficient solutions for integrating Ethernet-APL field devices in small test setups, as well as for large process plants. As part of the EtherCAT Terminal system, the ELX6233 can be combined with other digital and analog I/Os so that standard electrical signals or communication protocols can be integrated in addition to Ethernet-APL. Direct connection to CX Embedded PCs also offers a whole host of advantages, one of which is allowing NOA applications to process data from the field and filter it before sharing it further.

Like many of the EtherCAT Terminals from the Beckhoff portfolio, the ELX6233 can be mounted in zone 2 explosive atmospheres and allows Ethernet-APL field devices to be connected from zone 0. The interfaces comply with the specifications of IEC 60079-47 and are in accordance with the SPAA port profile.

Ethernet-APL leads to further challenges in terms of IT and OT security due to end-to-end Ethernet communication. Unlike many PROFINET architectures, the controller is located directly in the EtherCAT Terminal and not in the higher-level controller. This design offers users the option to filter all data traffic through the terminal and install a firewall. Compared to a field switch, the terminal also cuts down on opportunities to gain unauthorized access to process data. This architecture even elicits further advantages in terms of the application’s performance. The point-to-point connection to the sensor eliminates the risk of overloading the network due to unwanted cross-traffic, which is a well-known problem in conventional PROFINET networks. System cycle times can also be reduced as EtherCAT facilitates a more compact data size for the process image compared to other fieldbuses.

TwinCAT MTP for consistently modularized systems

One of the emerging challenges for many industries in the process industry, such as the pharmaceutical industry, is increasing fluctuation across sales markets. This is accompanied by the need for a shorter time-to-market due to accelerated development cycles. Product life cycles are shortened accordingly, and these in particular require economically profitable and simultaneously individualized production of small batches.

An increasingly popular solution is designing plants to be modular, which provides the option to reuse the modules for different purposes. This involves breaking down the plant’s entire process into individual sub-processes and mapping them using modules. Full plant modularity can then be achieved with a separate, decentralized controller for each module. The entire process can be remapped by subsequently integrating the individual modules into a higher-level control system (e.g., a DCS). As a result, the development work shifts from plant engineering to module engineering, enabling the plant to be flexibly modified with little effort, depending on current requirements. Additional modules can be added to the plant and modules that have already been integrated can be rearranged or removed. Complete reprogramming is not required, as most of the logic is encapsulated in the individual modules. The higher-level controller only handles the orchestration of the modules and the services they offer, and is therefore referred to as the process orchestration layer (POL).

“The modularity of the MTP (module type package) concept revolutionizes process plants design and offers advantages such as a rapid time-to-market, increased flexibility, and the ability to produce small batches economically. MTP’s standardized interfaces simplify the plug-and-play integration of specialized modules into a process orchestration layer and enable seamless operation. TwinCAT MTP offers an environment for easy development of modules via automatic code generation. This approach minimizes the need for in-depth knowledge of the specification. In practice, it simplifies module development and makes the benefits of modularity accessible and efficient for professionals in the process industry.” – Laurids Wetzel, Process Industry Management

In practice, the concept is implemented by a manufacturer-independent standard for the description of process modules: the module type package (MTP). Initiated by NAMUR and ZVEI, the MTP contains all the information needed to integrate a process module into a modular plant, including functions in the form of services, communication, and an HMI template. Interfaces defined in the MTP guideline enable plug-and-produce behavior, eliminating the work and costs associated with reusing a plant. This means modules are only developed once and can then be integrated into other plants independently of the controller manufacturer and POL.

MTP is seen as an essential component of digital transformation in the industrial sector. The general expectation is that using MTP will significantly improve plant KPIs. Experts predict that the time-to-market can be halved on average, engineering costs can be reduced by 70%, and flexibility can be increased by 80%.

Summary

With NAMUR Open Architecture and PA-DIM, the process industry is laying the foundations for standardized and structured mapping of heterogeneous systems in higher-level analysis tools. This means that existing plants can be digitalized right now and reap the benefits, including a reduction in maintenance costs. The idea of a standardized data model such as PA-DIM is also an interesting topic for the future, independent of NOA. For example, system sections could be combined in gateway applications and forwarded to the DCS in defined information models. The DCS would therefore be independent of the sensor’s process image, enabling smooth exchange for the field device across different manufacturers. Furthermore, control loops can be implemented on a decentralized basis to relieve the DCS and reduce data traffic.

A similar approach is pursued in the MTP concept, where the plant is structured on a modular basis. Each module is equipped with its own controller, which is integrated into the automation architecture via a standardized interface description. This allows the MTP to flexibly adapt production to the market situation by varying the modules used. Individual modules can also be replaced quickly and easily in the event of a fault, thus reducing downtime.

The modular approach is also continued in the integration of Ethernet-APL into the Beckhoff portfolio. Instead of large field switches, APL field devices are integrated using compact EtherCAT Terminals. These can be flexibly combined with other terminals – for example, for communication with digital sensors. Direct integration with a controller also offers further possibilities for gateway or edge applications. Ethernet-APL and NOA already work together seamlessly with the help of Beckhoff Automation Technology.

“Increasing the availability, efficiency, and flexibility of plants is key when it comes to optimal plant operation. This requires innovative digital technology. Field device data must be transmitted quickly and in full, even in sprawling plants, to enable seamless monitoring and continuous process optimization. The system could also be modularized so that companies can respond to constantly changing market requirements flexibly. With PC-based control from Beckhoff and our products and solutions for NOA, Ethernet-APL, and MTP, you can meet these requirements and automate your plant to make it fit for the future.” – Franziska Rostan, Process Industry Management