The AL8124 linear servomotor is suitable for highly dynamic and powerful linear axes for 48 V DC and has a pole pair distance of 24 mm. The optimized product design and the modular coil concept enable maximum force density in the smallest mounting space. The length of the primary part is 239 mm. The AL8124 attains a maximum velocity of 1.7…3.5 m/s with a peak force Fmax of 440 N. Cooling is by convection.

Symmetrical and flexible motor design

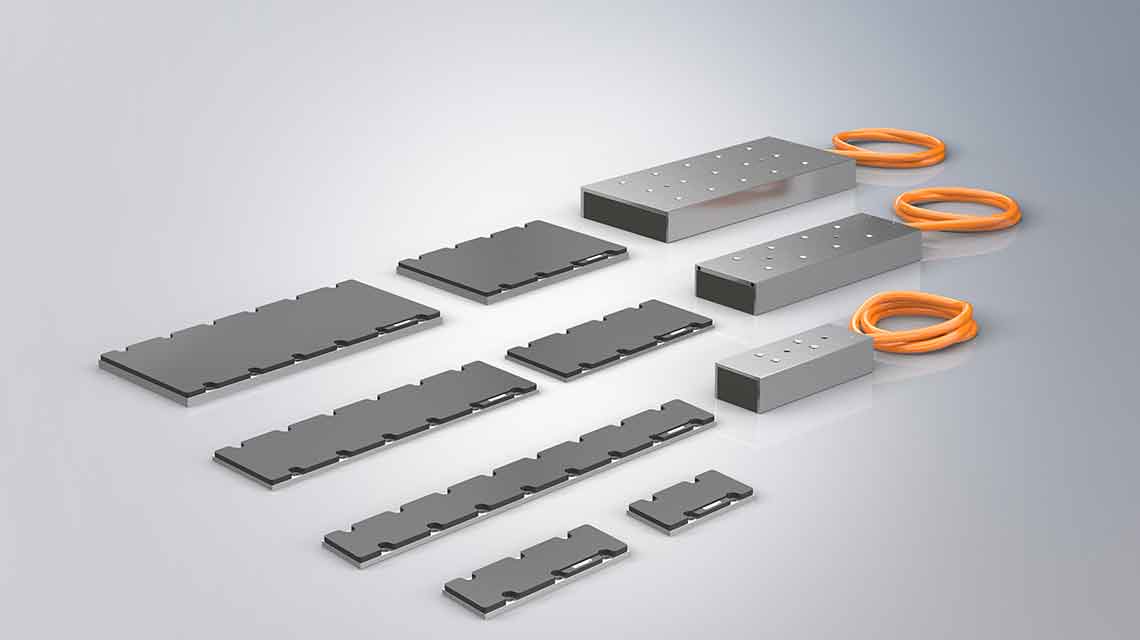

The AL8100 linear motors have a symmetrical drilling pattern that simplifies the construction and allows a universal machine design. In addition, critical hotspots are avoided by enabling the even contact of the linear motor with the machine slides.

High force density

The modular coil concept allows a flexible and very compact design of the linear motor. The space-saving linear motors from the AL8100 series feature high peak forces despite their compact design and thus offer optimum force density.

One Cable Technology

The primary parts can be equipped with One Cable Techonolgy (OCT) as an option. Here, the scanning head of the linear encoder forms a single unit together with the primary part, both mechanically and electrically. As a result, only one cable is required to supply power and connect the feedback system and thermal sensor. In addition to cutting down on wiring work and thus speeding up electrical installation, commissioning is also simplified by an online evaluation number stating the encoder's signal quality and the electronic nameplate. All relevant motor parameters are read out directly upon connection to the ELM72xx servomotor terminals. In addition, scanning head no longer needs to be mechanically installed as it is automatically fitted when the primary part is installed.

The complete system requires additional components, such as the scale tape and the rail for easy mounting of the scale tape.

Product status:

regular delivery | estimated market release of the OCT version on request

Product information

| Data for 24 V AC | AL8124-0Jyz-0000 |

|---|---|

| Motor type | 3-phase synchronous linear servomotors |

| Nominal voltage | 24…48 V DC |

| Max. speed | 1.7 m/s |

| Peak force | 440 N |

| Continuous force | 240 N |

| Peak current | 16 A |

| Continuous current | 7.3 A |

| Force constant | 33 N/A |

| Cooling | convection |

| Connection technology | M23 speedtec® plug |

| Ambient temperature (operation) | +5…+40°C |

| Approvals/markings | CE, cURus, EAC |

| Housing data | AL80xx | W2 |

|---|---|

| Protection rating | IP64 |

| Overall width | W2 (50 mm) |

| Material | aluminum |

| Dimensions | AL8124-0Jyz-0000 |

|---|---|

| b | 51 mm |

| la | 239 mm |

| h | 40 mm |

- Continuous operation @ 24 V DC

- Continuous operation @ 48 V DC

- Voltage boundary curve @ 24 V DC

- Voltage boundary curve @ 48 V DC

| Order reference

AL8124-wxyz-0000 | |

|---|---|

| w = 0 | convection cooling |

| x | winding code A…Z |

| y = 0 | without feedback |

| y = 1 | One Cable Technology for power and feedback: feedback transmission via motor cable, no feedback cable necessary, inductive scanning head, absolute position, 0.1 µm resolution, product announcement | estimated market release on request |

| z = 0 | 1.00 m connection cable with wire end ferrules |

| z = 1 | 0.50 m connection cable with plug |

| All electric quantities are RMS values. | |

| The options cannot be installed in the field. |

Loading content ...

Loading content ...

© Beckhoff Automation 2025 - Terms of Use