Simple, flexible and cost-effective machine safety implementation

IMA Klessmann GmbH, Germany

Simple, flexible and cost-effective machine safety implementation

IMA Klessmann GmbH, Germany

Headquarters Australia

Beckhoff Automation Pty. Ltd.

+61 3 9912 5430

info@beckhoff.com.au

www.beckhoff.com/en-au/

IMA Klessmann GmbH, Germany

IMA Klessmann GmbH, Germany

Furniture manufacturers and their mechanical engineering partners face major challenges every day when it comes to fulfilling maximum part throughput with a high degree of individualization (keyword: lot size of one) and the highest quality requirements with strong cost pressure at the same time. The solution lies in an automation technology with a drastically simplified system structure and the consistent use of IT standards, as offered by Beckhoff with PC-based control.

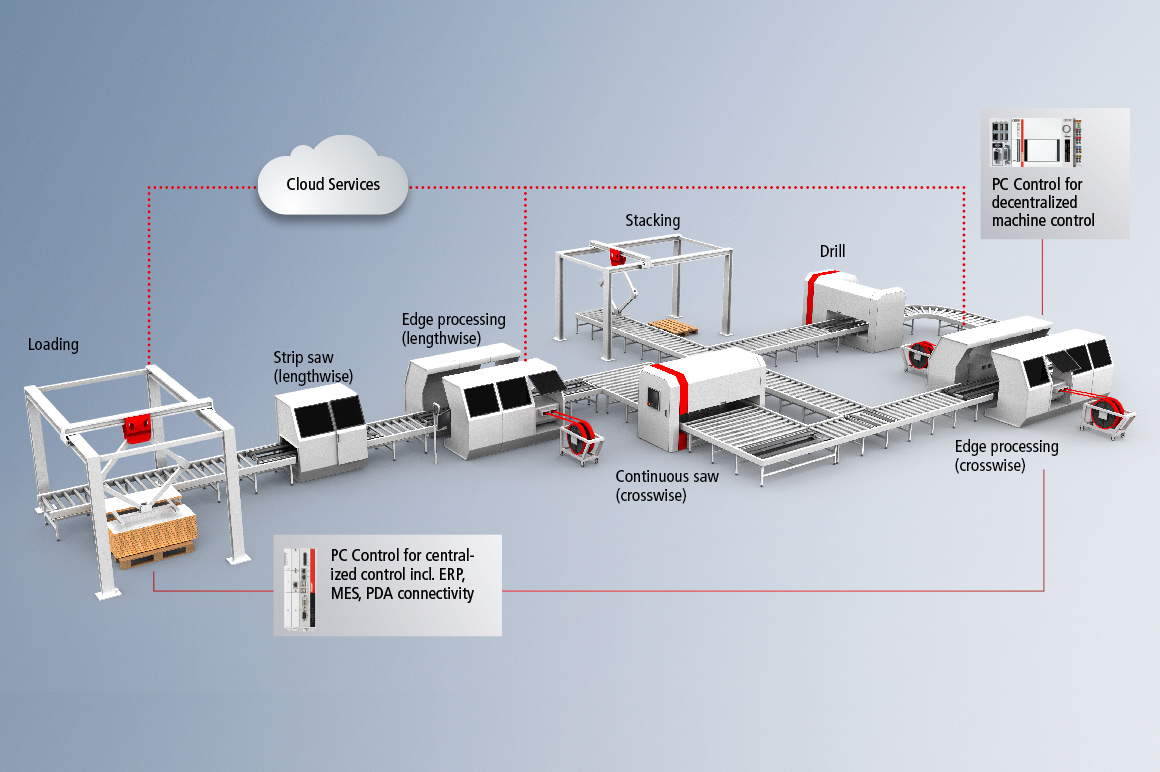

Whereas hardware platforms tailor-made for specific purposes are often used in classic machine controllers for the different functions, the PC-based controller consistently maps all functions in software modules and executes them on the Industrial PC. The immediate consequences are a significantly reduced communication effort, shorter response times and reduced costs, both for hardware and for engineering. The lower control complexity leads to higher reliability and simpler maintenance of machines and plants while eliminating a large number of components. Modular in structure and exactly scalable in terms of performance requirements, PC-based control from Beckhoff is suitable for the entire range of requirements in woodworking: it is used both in primary processing, for example for the automation of complete sawmills, as well as in secondary processing, for example for the production of furniture. It is equally suitable for controlling the individual craftsman's machine or for industrial plant linking, consisting of transport, loading/de-stacking and edge/CNC/drilling machining as well as surface treatment systems.

All machine and plant functions, from the PLC and Motion Control to NC/CNC, robotics and HMI – including vision, safety and measurement technology as required – are mapped in software and run on one platform. Depending on the type of machine, other software modules, such as parts tracking, CAD/CAM interfaces, drill and saw cutting optimizers, MDE/BDE and local databases are required. This wide variety is no problem for the IPC due to the high performance of multi-core and many-core processors. Depending on the selected system architecture, these functions either also run on the control computer or are outsourced to a separate computer as required. This is often the case with control systems. The master computer is then coupled to the control computer via standardized interfaces.

With open interfaces in hardware and software, PC-based control offers machine manufacturers high degrees of freedom in their machine design. This flexibility allows them to integrate a variety of different devices, including from third-party manufacturers. This ensures efficient interaction of all system components and enables maximum productivity. Support for common fieldbus systems and software protocols also guarantees universal horizontal and vertical communication, from the networking of the individual machines to the IT level and the cloud.

As a result, the woodworking industry continues to rely on this proven and highly innovative control platform. The expertise in the wood industry acquired over decades of cooperation with machine manufacturers and end customers makes Beckhoff a reliable partner with a high level of solution competence. The Beckhoff industry management team and the engineering department offer machine manufacturers comprehensive application support for both new plants and machine retrofits.

Wood is a natural and renewable raw material, which means it rarely arrives in pristine condition. This is why the Finnish company Raute, which claims to be the global market leader in veneer, plywood, and LVL (laminated veneer lumber) production technology, also offers repair systems that automatically detect and repair defects. A combination of AL8000 linear motors and AX5000 servo drives from Beckhoff ensure the necessary high precision and dynamics.

In 2017, Nobilia, Europe’s largest kitchen manufacturer, based in Verl, Germany, delivered an astounding 675,000 individually assembled kitchens. The company’s intelligent, highly efficient production logistics and consistent transparency in parts and production data make this possible.

In 2017, IMA Klessmann modernized a complex, multi-track transport system for wooden workpieces for kitchen cabinetry manufacturer, Fournier. In the process, a reliable monitoring system that prevents unauthorized entry was implemented in an extremely simple, flexible and cost-effective way using analog sensors and TwinSAFE SC safety technology.

The mortise and tenon wood joining technique used in traditional furniture making is a complex procedure. The machine developed by Nantong Guoquan enables the automatic manufacturing of mortise and tenon joints that also differ in shape, size and execution.

PC-based control from Beckhoff offers the ideal foundation for universal transparency of the parts and production data, entirely in keeping with the ideals of Industry 4.0.