Beckhoff offers an integrated stainless steel control system with hygienic design for the food manufacturing, beverage, pharmaceutical and packaging industries. All stainless steel components meet the stringent requirements of hygiene and cleanroom regulations.

More about this video

EtherCAT Box

EtherCAT high-performance directly in the field: Beckhoff offers an I/O system in IP67 with the EtherCAT Box modules.

I/O

Beckhoff liefert ein umfangreiches Programm an Feldbuskomponenten für alle gängigen I/Os und Feldbussysteme.

IPC

We deliver Panels and Industrial PCs for every application – with the latest technology for all performance classes.

Motion

Our innovative drive technologies give you almost unlimited capabilities when it comes to realizing your application.

CP39xx, CP79xx | Stainless steel Control Panels

The CP39xx and CP79xx series in stainless steel design for particularly high hygienic requirements offer modern multi-touch or resistive touch technology.

EQxxxx | Stainless steel housing

IP69K modules for extreme harsh and corrosion-prone environments.

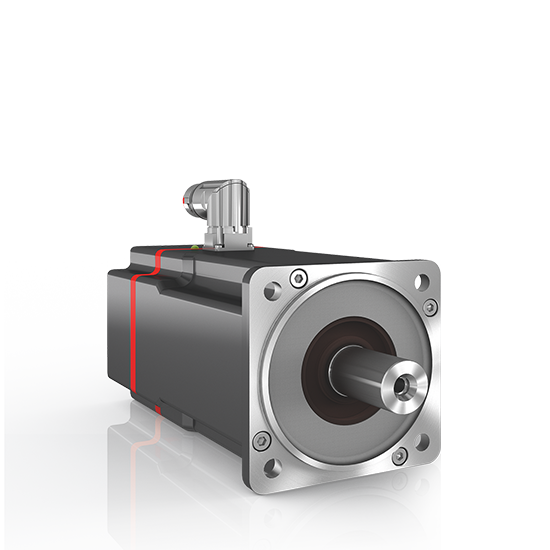

AM8800 | Stainless-steel motors with hygienic design

The AM8800 motors are ideal for extremely harsh environmental conditions. The highest protection rating and stainless steel surfaces defy aggressive media.

CP7901-1400-0010 | Stainless steel Control Panel in IP65 with 12-inch display

The CP79xx Control Panels in a stainless steel finish are display units that meet the strict hygiene regulations for the food, packaging and medical industries as well as for cleanrooms. The stainless steel Panels with IP65 protection feature virtually gap less housing design with flush-mounted touch screens. The housing geometry and an optimized frame profile allow liquids to run off and prevent the accumulation of contamination. Further features, such as the resistance of the stainless steel surface and the touch screen to cleaning agents and disinfectants, cover all requirements for cleanroom applications.

CP7901-1401-0010 | Stainless steel Control Panel in IP65 with 12-inch display, customer-specific variant

The CP79xx Control Panels in a stainless steel finish are display units that meet the strict hygiene regulations for the food, packaging and medical industries as well as for cleanrooms. The stainless steel Panels with IP65 protection feature virtually gap less housing design with flush-mounted touch screens. The housing geometry and an optimized frame profile allow liquids to run off and prevent the accumulation of contamination. Further features, such as the resistance of the stainless steel surface and the touch screen to cleaning agents and disinfectants, cover all requirements for cleanroom applications.

CP7902-1400-0010 | Stainless steel Control Panel in IP65 with 15-inch display

The CP79xx Control Panels in a stainless steel finish are display units that meet the strict hygiene regulations for the food, packaging and medical industries as well as for cleanrooms. The stainless steel Panels with IP65 protection feature virtually gap less housing design with flush-mounted touch screens. The housing geometry and an optimized frame profile allow liquids to run off and prevent the accumulation of contamination. Further features, such as the resistance of the stainless steel surface and the touch screen to cleaning agents and disinfectants, cover all requirements for cleanroom applications.

CP7902-1401-0010 | Stainless steel Control Panel in IP65 with 15-inch display, customer-specific variant

The CP79xx Control Panels in a stainless steel finish are display units that meet the strict hygiene regulations for the food, packaging and medical industries as well as for cleanrooms. The stainless steel Panels with IP65 protection feature virtually gap less housing design with flush-mounted touch screens. The housing geometry and an optimized frame profile allow liquids to run off and prevent the accumulation of contamination. Further features, such as the resistance of the stainless steel surface and the touch screen to cleaning agents and disinfectants, cover all requirements for cleanroom applications.

CP7903-1400-0010 | Stainless steel Control Panel in IP65 with 19-inch display

The CP79xx Control Panels in a stainless steel finish are display units that meet the strict hygiene regulations for the food, packaging and medical industries as well as for cleanrooms. The stainless steel Panels with IP65 protection feature virtually gap less housing design with flush-mounted touch screens. The housing geometry and an optimized frame profile allow liquids to run off and prevent the accumulation of contamination. Further features, such as the resistance of the stainless steel surface and the touch screen to cleaning agents and disinfectants, cover all requirements for cleanroom applications.

CP7903-1401-0010 | Stainless steel Control Panel in IP65 with 19-inch display, customer-specific variant

The CP79xx Control Panels in a stainless steel finish are display units that meet the strict hygiene regulations for the food, packaging and medical industries as well as for cleanrooms. The stainless steel Panels with IP65 protection feature virtually gap less housing design with flush-mounted touch screens. The housing geometry and an optimized frame profile allow liquids to run off and prevent the accumulation of contamination. Further features, such as the resistance of the stainless steel surface and the touch screen to cleaning agents and disinfectants, cover all requirements for cleanroom applications.

EQ1008-0002 | EtherCAT Box, 8-channel digital input, 24 V DC, 3 ms, M12, stainless steel

The EQ1008-0002 EtherCAT Box with digital inputs acquires the binary control signals from the process level and transmits them, in an electrically isolated form, to the controller. The state of the signals is indicated by light emitting diodes. The signals are connected via M12 screw type connectors.

EQ1809-0022 | EtherCAT Box, 16-channel digital input, 24 V DC, 3 ms, M12, stainless steel

The EQ1809-0022 EtherCAT Box with digital inputs acquires the binary control signals from the process level and transmits them, in an electrically isolated form, to the controller. The state of the signals is indicated by light emitting diodes. The signals are connected via M12 screw type connectors.

EQ2008-0002 | EtherCAT Box, 8-channel digital output, 24 V DC, 0.5 A, M12, stainless steel

The EQ2008-0002 EtherCAT Box is intended for processing digital/binary signals. It relays the binary control signals from the controller to the actuators at the process level. The eight outputs handle load currents of up to 0.5 A. A short-term overload is possible. The outputs are short-circuit proof. The total current of all outputs is limited to 4 A. The signal status of the channels is indicated by LEDs, the signals are connected via M12 screw type connectors. One channel is available per M12 socket.

EQ2809-0022 | EtherCAT Box, 16-channel digital output, 24 V DC, 0.5 A, M12, stainless steel

The EQ2809 EtherCAT Box with digital outputs connects the binary control signals from the controller on to the actuators at the process level. The 16 outputs handle load currents of up to 0.5 A each, although the total current is limited to 4 A. This makes these modules particularly suitable for applications in which not all of the outputs are active at the same time, or in which not all of the actuators draw 0.5 A current.

EQ2339-0022 | EtherCAT Box, 16-channel digital combi, 24 V DC, 3 ms, 0.5 A, M12, stainless steel

The EQ2339 EtherCAT Box has 16 digital channels, each of which can optionally be operated as an input or as an output. A configuration for using a channel as input or output is not necessary; the input circuit is internally connected to the output driver, so that a set output is displayed automatically in the input process image.

EQ3174-0002 | EtherCAT Box, 4-channel analog input, multi-function, ±10 V, 0/4…20 mA, 16 bit, differential, M12, stainless steel

The EQ3174 EtherCAT Box has four analog inputs which can be individually parameterized, so that they process signals either in the -10…+10 V or the 0/4…20 mA range. The voltage or input current is digitized with a resolution of 16 bits, and is transmitted (electrically isolated) to the higher-level automation device. The four input channels have differential inputs and possess a common, internal ground potential. The input filter and therefore the conversion times are configurable in a wide range. If required, the inputs can be scaled differently, and automatic limit monitoring is also available. EtherCAT is used for parameterization purposes. The parameters are stored in the module.

EQ3204-0002 | EtherCAT Box, 4-channel analog input, temperature, RTD (Pt100), 16 bit, M12, stainless steel

The EQ3204 EtherCAT Box with analog inputs allows resistance sensors to be connected directly. The module’s circuitry can operate the sensors using 2-, 3- or 4-wire connection techniques. Linearization over the full temperature range is realized with the aid of a microprocessor. The temperature range can be selected freely. The module can also be used for simple resistance measurement with the output in ohms. The module’s standard settings are: resolution 0.1°C in the temperature range of Pt100 sensors in 2-wire connection. Sensor malfunctions such as broken wires are indicated by error LEDs. The module is quite versatile, but the default values are selected in such a way that in most cases it is not necessary to perform configuration. The input filter and associated conversion times can be set within a wide range; several data output formats may be chosen. If required, the inputs can be scaled differently. Automatic limit monitoring is also available. Parameterization is carried out via EtherCAT.

EQ3314-0002 | EtherCAT Box, 4-channel analog input, temperature, thermocouple, 16 bit, M12, stainless steel

The EQ3314 EtherCAT Box with analog inputs permits four thermocouples to be directly connected. The module’s circuit can operate thermocouple sensors using the 2-wire technique. Linearization over the full temperature range is realized with the aid of a microprocessor. The temperature range can be selected freely. The error LEDs indicate a broken wire. Compensation for the cold junction is made through a temperature measurement in the connecting plugs. This means that standard extension leads can be connected. The EP3314 can also be used for mV measurement.

Packaging machines

PC-based control significantly increases the productivity and flexibility of packaging machines and lowers the consumption of resources.