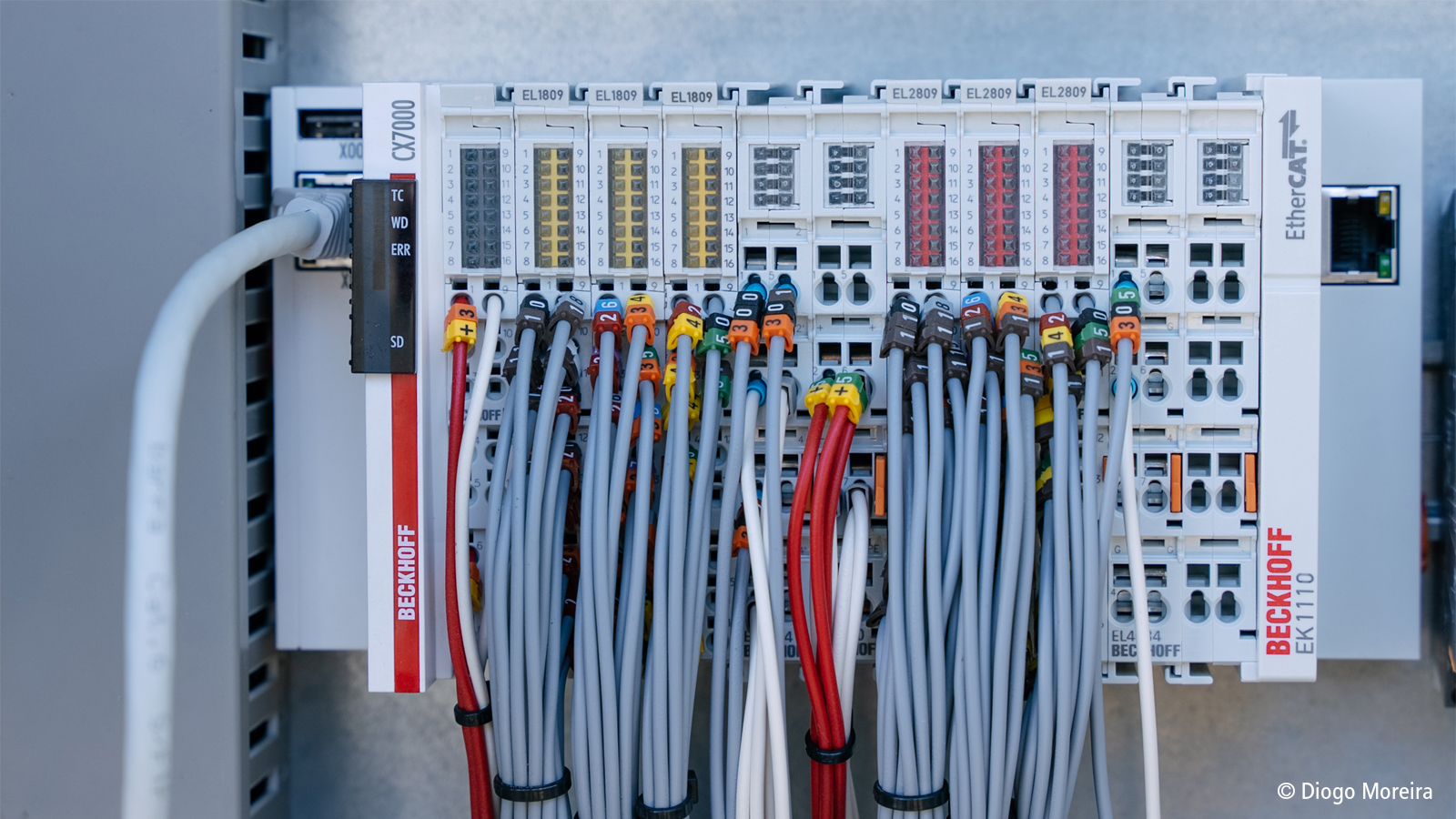

CX7000 Embedded PC and EtherCAT Terminals in construction machinery for quarrying

Even if it seems like quarrying construction machinery only has to do rough work, precise and efficient control technology is still essential. This is particularly true for unmanned, remote-controlled machines such as those being developed by the Portuguese specialist Fravizel. Supported by Bresimar, a Beckhoff distributor, the company selected a very compact combination: the CX7000 Embedded PC and EtherCAT Terminals form the foundation of their future-proof and robust control solution.

Fravizel is a Portuguese company with over 39 years of experience in designing and manufacturing earth-moving equipment, as well as machinery for quarrying, forestry, and industry, such as diamond wire cutting and drilling machinery. Present on five continents, the company says its ability to innovate is essential in enabling it to meet the manifold equipment needs of its worldwide and diverse customer base. A member of Fravizel engineering team explains why they implemented PC-based control here: "Beckhoff distributor Bresimar suggested the CX7000 as a potential solution. We were not aware of this embedded PC, so we analyzed it and realized that it is an extremely compact device that has all the necessary processing and storage functions. It was also compatible with the Beckhoff products and solutions we were already using. Our partnership with Bresimar was also very important for technical development, as we received all the support we needed."

A compact and robust control solution

The machines that the CX7000 Embedded PC will be implemented in are unmanned and can only be controlled remotely by specialized operators. This equipment is intended for use in quarries, for cutting and processing ornamental stone. The controls needed to be modernized, so Fravizel began the search for an extremely compact and robust solution, and found that the CX7000 and Beckhoff I/O technology were a great option, which also ensured compatibility with the EtherCAT communication protocol that was already in place. According to the engineering team, the high computing and storage capacity of the compact controller covers all requirements for proper machine operation.

The CX7000 functions as an EtherCAT master, which enables the broad EtherCAT I/O portfolio from Beckhoff to be deployed in conjunction with a very compact and cost-effective device. The controller can thus be used in a wide variety of systems. Automation & Control team states that EtherCAT had already been used in communication between the control components of the machines and proved to be one of the major advantages of the Beckhoff control solution, as third-party hardware can be integrated much more flexibly than it can with other systems.

The hydraulic and pneumatic circuits are crucial for assuring proper function of the construction machines. EtherCAT analog terminals, including EL3004, EL3174, EL4032, EL4034 and EL4038, can be used to precisely control the flow and pressure of the proportional valves, which are important variables here, and to record system performance. The EL1809 and EL2809 EtherCAT digital terminals are used, among other things, as command inputs and for sensors, or as outputs for hydraulic/pneumatic solenoid valves and power and control drives.

Machines with extendable arms, central axis rotation and/or lateral displacement also require positioning control for the various machine segments, which is provided by the EL5001 and EL5002 EtherCAT encoder terminals forming a control loop with absolute encoders. To provide reliable pressure monitoring for the hydraulic and pneumatic systems, EL3024 EtherCAT input terminals collect the analog signals from pressure, fill level, inclination, and temperature sensors positioned throughout the machine.

Future-proofing through technology

Looking to the future, Fravizel believes it is critical that a control system has longevity and is also suitable for other projects. If more signal types are required, for example, additional EtherCAT Terminals can simply be added to the CX7000 Embedded PC. According to Bresimar, the CX7000, which unites compact design with high functionality, is perfect for Fravizel and is just the first step into using scalable PC-based control technology from Beckhoff. Fravizel and Bresimar will maintain a close relationship with the customer to create innovative solutions with added value for the equipment developed, as well as to enable growth and knowledge sharing.