PC-based automated production system for photo calendars

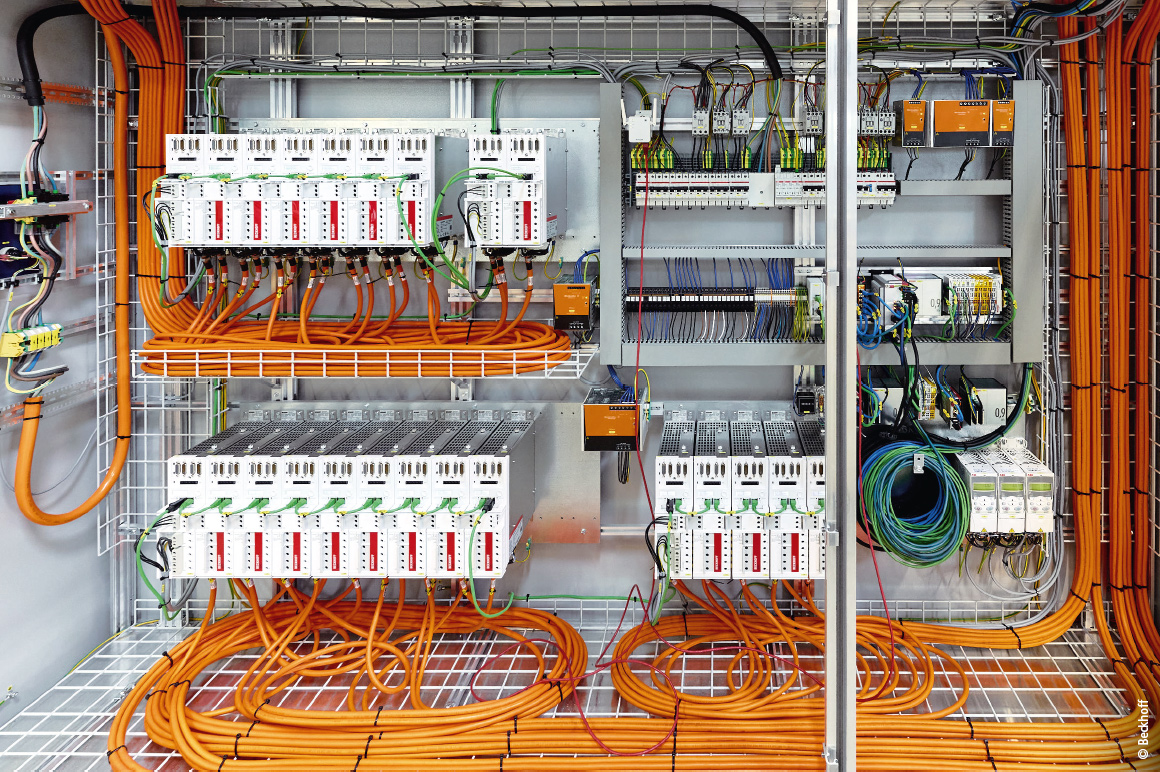

Durrer Spezialmaschinen AG, based in Immensee, Switzerland, develops – from the design phase to commissioning and more – a wide variety of special-purpose machines. A new production system for photo calendars proves at first glance the particular importance of comprehensive motion control expertise: AM8000 servomotors and AX5000 servo drives from Beckhoff for over 90 dynamically controlled axes are distributed over a system length of 15.5 m housed in two large control cabinets.

The two-part FOURCUT/WIRO 500 system automates the processing steps between printing and the packaging or logistics line, which were previously often still performed manually. It is highly flexible and can process products in a wide range of paper formats and qualities from both digital and offset printing. In addition to wall calendars, desktop calendars can also be produced directly from the pallet or gathering machine. This is only possible due to a high degree of automation, which ensures short set-up and changeover times, reliable system operation by just one or two people, and a high output of 1,600 to 1,800 calendars per hour.

The system consists of a FOURCUT for counting and cutting the signature sheets into individual sections and the fully automatic WIRO 500 processing line for punching holes and ring binding or stacking and sorting for successive packaging and logistics steps. The WIRO 500 was specially designed for assembling photo calendars and in particular to meet the growing demand for lot-size-of-one production, individualized small quantities, and special product designs – whether for private photo calendars or in the promotional and giveaway sector.

Sophisticated movements and high quality

A total of 93 axes – realized using AX5000 servo drives and AM8000 servomotors – take over the sophisticated process sequences. The system also integrates a gathering machine via digital I/Os and a SCARA robot via PROFINET. In addition, there are numerous testing and monitoring functions to ensure high product quality, e.g., to compensate for deviations in the printing image from different presses. All of this is automated using PC-based control technology from Beckhoff. According to Patrick Suter, Durrer CTO, the broad and finely scalable product portfolio offers particular advantages for a custom machine builder: “PC-based control technology is also ideal for installing the required third-party software, e.g., for the robot, a QR code reader, or the inspection camera, on a computer. We have consistently relied on Beckhoff Drive Technology for eleven years because it has proven to be a homogeneous and highly coordinated PLC, motion, and safety system.”

Nicola Ritzmann, head of mechanical development at Durrer, adds: “The servo drives and servomotors are extremely reliably, which is very important for our machines. In addition, we’ve been able to set up every axis and implement every motion application so far, even if the axis requirements have changed during commissioning. Not to mention the fact that we can always count on the experts from Beckhoff Switzerland or Verl for support whenever we need it. The implementation process is also simplified by the fact that Beckhoff continuously develops its software with numerous function blocks. For example, we were able to perfectly optimize a challenging axis in a master-slave network using the new Bode diagram.” The One Cable Technology (OCT) provided by Beckhoff drive technology offers tangible cost benefits due to fewer cable routings and smaller drag chains, resulting in less material and assembly time overall.

Ultra-compact and communicative industrial PCs

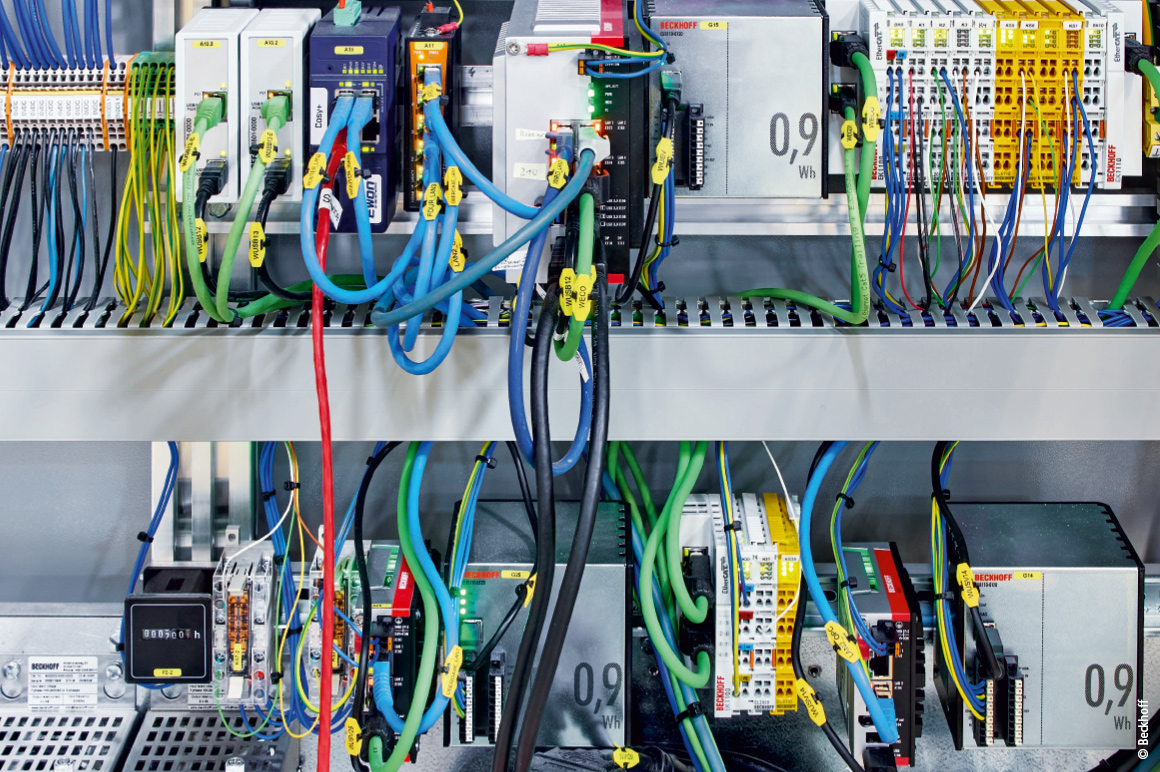

In line with modular machine building, Durrer uses several Beckhoff computers – which communicate with each other via the EAP protocol – to control the FOURCUT/WIRO 500. According to Patrick Suter, the ultra-compact industrial PCs were chosen for this primarily due to their perfectly scalable computing power, compact design, and numerous communication interfaces: One C6030 each for the FOURCUT and the WIRO 500, as well as one C6015 each for an optional transfer module and OPC UA communication with the higher-level customer system.

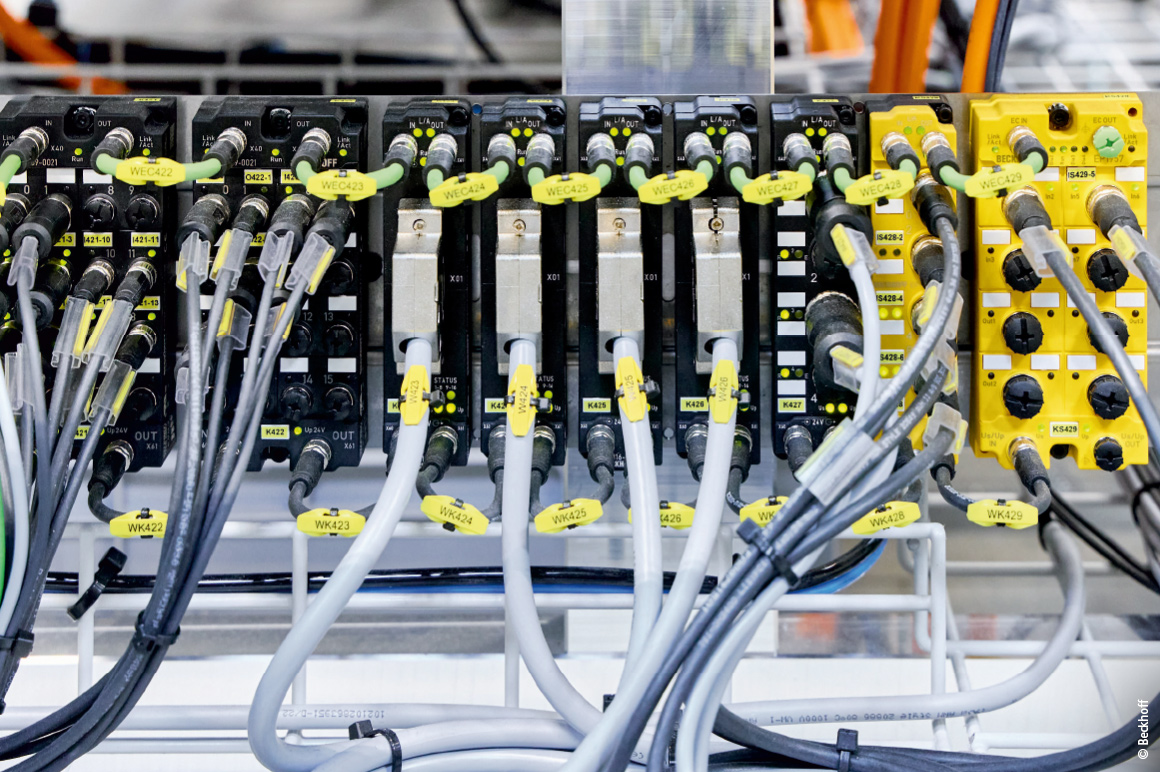

Patrick Suter explains his experience with the communication skills in the context of PC-based control: “With its topology freedom, EtherCAT enables us to create a simple fieldbus architecture that is perfectly tailored to the machines. To simplify wiring, over 98% of the signals are recorded directly on the machine using EtherCAT Box modules from the EP series: 62 in the FOURCUT and 52 in the WIRO 500. This explains why we absolutely require such a high-performing and robust fieldbus. Due to the widespread use of EtherCAT, we can also integrate numerous third-party components such as EtherCAT-enabled encoders, directly into the network. And the EAP protocol has also proven to be a fast, simple, and reliable solution for control-to-control communication.”

Patrick Suter describes another aspect of communication: “The comprehensive and reliable data collection forms the basis for real predictive maintenance. We can quickly localize and rectify faults and evaluate data, for example, to assess the influence of different faults on the duration of machine downtimes. This offers great potential for process optimization.” The necessary safety functions are also integrated into the system via Safety over EtherCAT, the EL6910 TwinSAFE Logic, and other TwinSAFE Terminals or box modules as well as the AX5805 TwinSAFE drive option cards: SOS, SS1, SS2, and SLS.

TwinCAT as a universal software solution

Just like the industrial PCs, the Beckhoff TwinCAT software also forms the heart of the system automation system. This is confirmed by Patrick Suter: “All machine sequences are programmed with TwinCAT 3 PLC/NC PTP, and the motion function blocks offer us an almost infinite number of very simple options for designing the movements for the corresponding function. Prime examples of this are master-slave combination, override, electronic gearing as well as MC_TorqueControl to switch an axis NC-guided to CST mode (torque control) and MC_MoveSuperImposed for relative superimposed movements. We’re very impressed by how easily the NC axes can be integrated into the PLC.” TwinCAT 3 HMI ensures convenient operation of the system.

In addition to the technical performance of PC-based control, Nicola Ritzmann believes that other aspects are also important: “The control and drive technology from Beckhoff offers high quality. This means that we are very rarely faced with system downtimes. And even if our system does come to a standstill, we can count on extremely fast and competent help from Beckhoff Switzerland and also from their headquarters in Verl – not just to ensure smooth system operation, but also during the project engineering phase.” Given that Durrer was recently appointed Beckhoff Solution Provider to support other PC-based control users with its comprehensive expertise is proof that this support is not required very often.