OCT | One Cable Technology

Power and feedback system in a single standard motor cable

Hoofdkantoor Nederland

Beckhoff Automation B.V.

Power and feedback system in a single standard motor cable

With One Cable Technology (OCT), Beckhoff offers an innovative connection solution for servomotors that does not require a separate feedback cable. Usually, a separate encoder cable is required to transmit the feedback information for commutation, position control, and winding temperature to the servo controller. OCT is a modified motor cable that uses both thermal contact wires for encoder communication. Transmission is thus extremely resistant to interference. In addition, analog signals are dispensed with entirely, which cuts down on work for the servo controller evaluation electronics as analog input modules are no longer needed.

A hybrid cable with additional wires for the encoder signals would be an alternative here, but it would be far more difficult to assemble, less flexible, and significantly more expensive due to its more complex structure. In addition, a hybrid cable has a greater diameter, which in turn requires a larger drag radius and takes up more space.

OCT is suitable for servo drives with a high nominal voltage range from 100 to 480 V AC as well as for compact drive technology with a low voltage of 24 to 48 V DC.

In servomotors with OCT, the feedback signals are transmitted directly to the power supply via the cable, so that the power and feedback systems are integrated via one motor connection cable. One Cable Technology sends the information through a digital interface reliably and without interference.

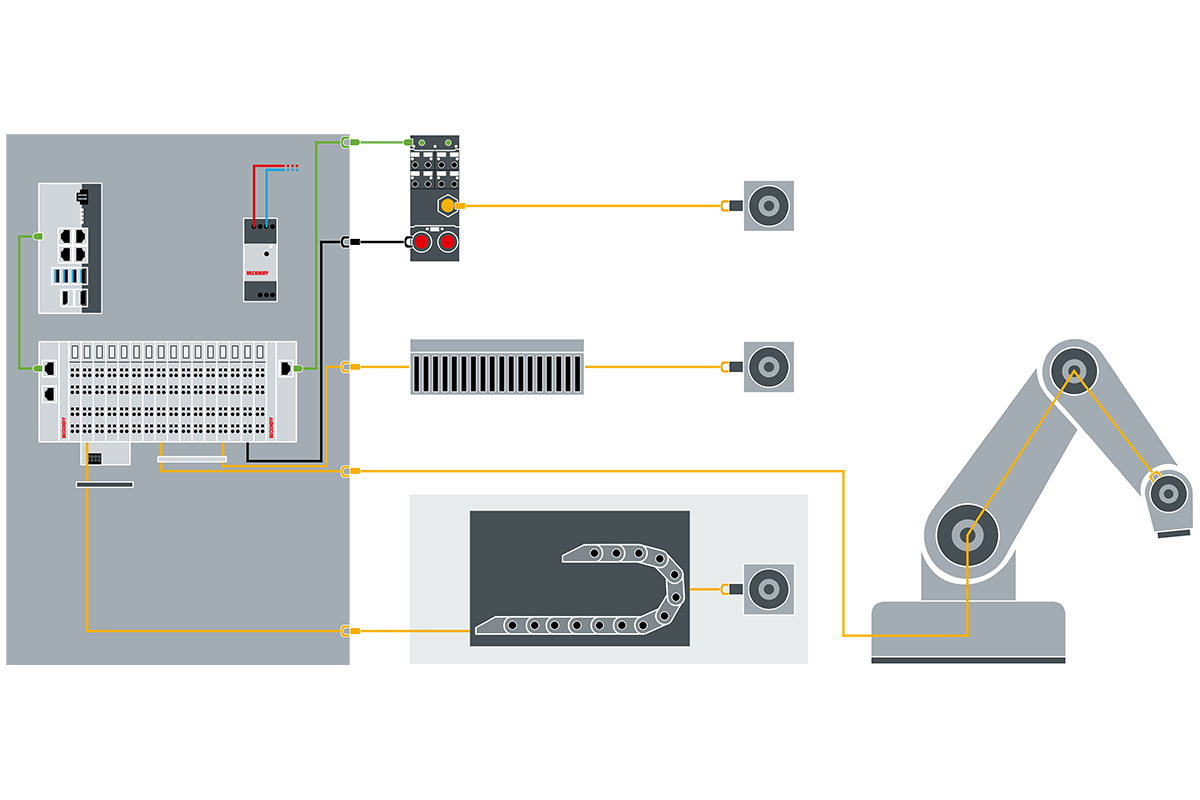

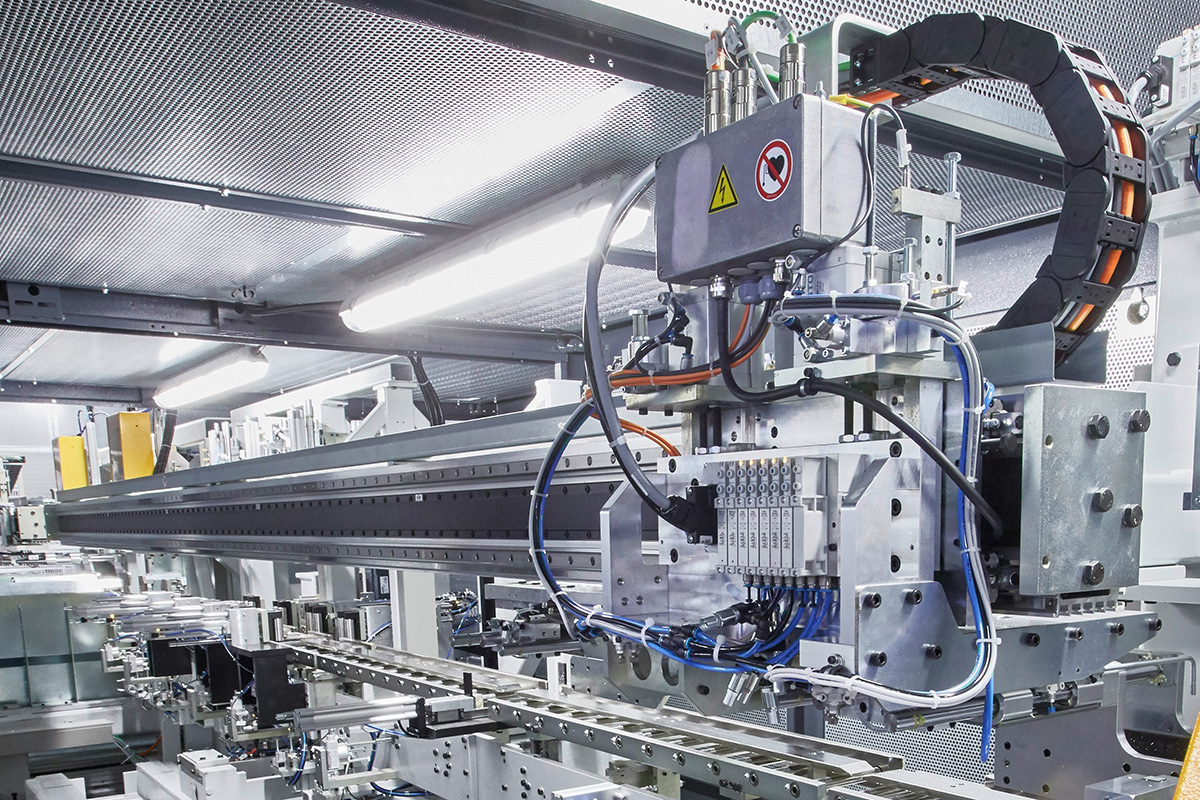

As the encoder cable is eliminated, fewer cables need to be pulled through the machine. The Machinery Directive states that power and encoder cables must be routed separately. Thus, separate cable channels must be installed. This is not the case with OCT.

In large installations with many motors, the risk of mixing up the cables is also eliminated; it is impossible to make the mistake of connectingencoder cable 1 to motor 2. The encoder is always directly assigned to the motor.

The feedback line is eliminated, which cuts motor costs, since the cost-intensive IP65/67 round plug and assembly, which can be extensive, are omitted.

Inventory costs are effectively halved.

As routing work is also halved, installation costs are reduced too.

OCT reduces the number of cables in drag chains (= narrower chains) and cable channels. This makes these components smaller and narrower, and thus less expensive.

Since a cable and connector are not needed for the motor and controller, the component and commissioning costs are reduced.

Drive technology is often found on moving elements, such as robots, multi-axis gantries, or pick-and-place robots. Here, limited space and oscillating mass play a major role.

By reducing the number of cables, the drag chains and cable channels also become smaller.

All OCT encoders allow access to all encoder data. This allows the encoder temperature, LED luminosity, and operating hours to be monitored.

The Beckhoff Smart System Diagnosis (B/SSD) ordering option also makes it possible to measure vibrations and humidity precisely and thus monitor the state of systems and servomotors in real time with minimal effort. This provides the basis for statistical evaluation with TwinCAT Analytics and effective predictive maintenance. Machine conditions and processes can therefore be monitored effectively and any necessary action taken in a timely manner to ensure efficient operation and maximum machine uptime.

B/SSD uses the proven One Cable Technology (OCT), which eliminates the need for additional sensors and sensor cables and significantly reduces wiring work.

With full integration in TwinCAT Analytics, live data and historical data can be recorded, clearly visualized, and processed into valuable information with B/SSD for machine optimization. Vibration measurements can be performed as an average value (RMS), with peak values (peak-to-peak), or statistically (kurtosis) up to ±50 g.

Compared to dual cable solutions, the cable length is not limited. The maximum length is 100 m, which matches standard EtherCAT and Industrial Ethernet cabling. The OCT cables are available for cost-optimized fixed installation with PVC sheathing or with PUR sheathing suitable for drag chains. A torsion cable with PUR sheathing can be used for robotic variants.

OCT cables are available for all motor series, including stainless steel motors or anodized motors in hygienic applications.

One Cable Technology is based on standard servomotor cables that have been tried and tested in the field over the course of many years. This technology has become a market standard that has been characterized and established by Beckhoff for over a decade. Over 90% of our motors are now supplied via OCT.

The AX1000 economy servo drive for implementing demanding and cost-sensitive drive tasks.

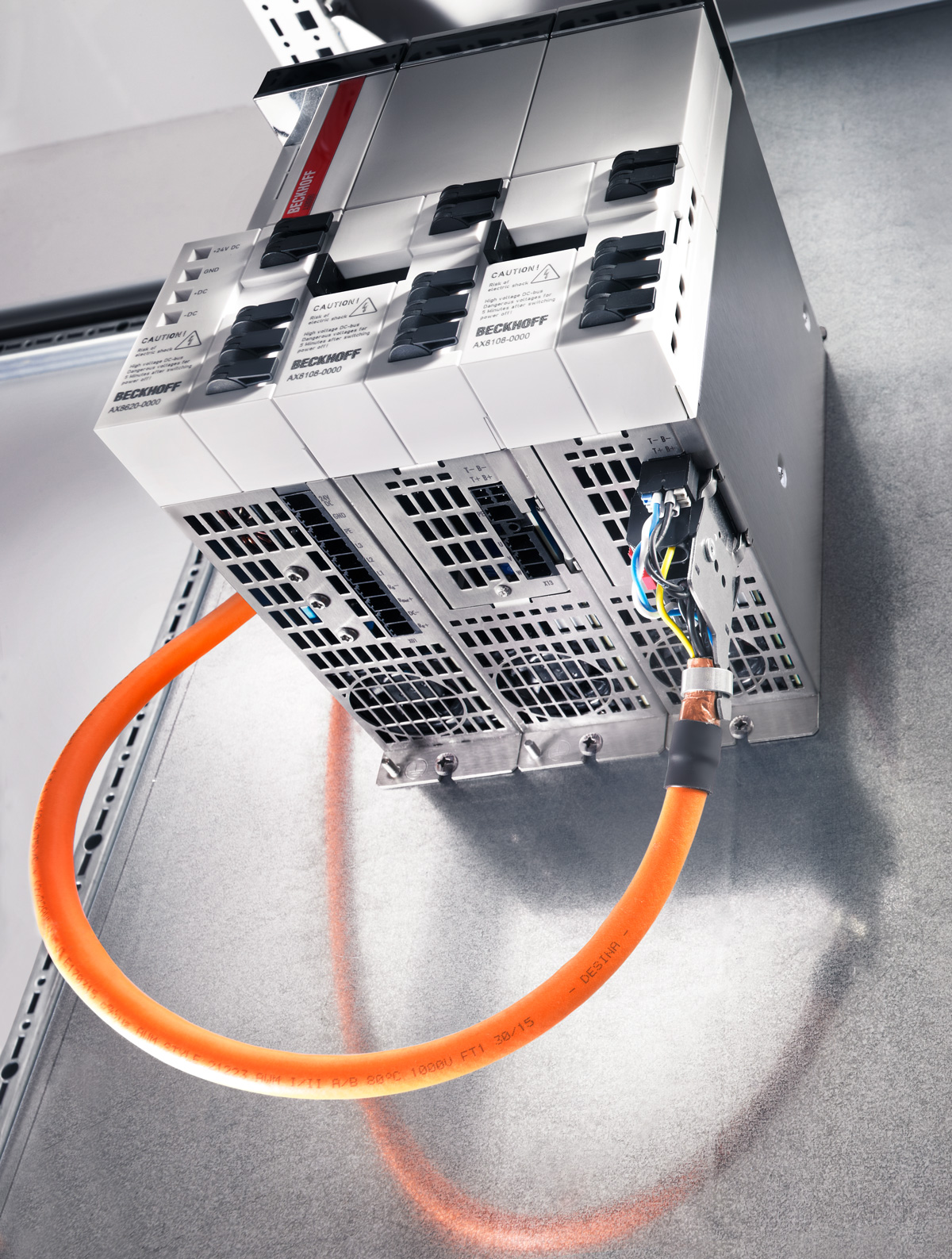

The AX8000 is the space-saving solution for applications with more than two axes. Extensive TwinSAFE functions allow a safe machine design.

The AX5000 is offered in a wide performance range and offers a flexible motor and feedback interface as well as optional TwinSAFE functions.

The AM1000 servomotors meet the highest technological demands with an optimized price/performance ratio for cost-sensitive applications.

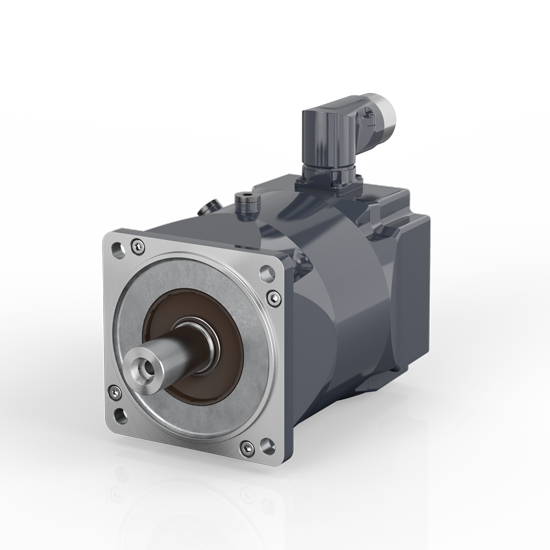

The AM8000 synchronous servomotors with One Cable Technology are suitable for applications with the highest demands on dynamics, speed and performance.

The AM8300 synchronous servomotors with integrated water cooling are suitable for applications with extreme demands on performance and dynamics.

The AM8500 motors with OCT provide an increased moment of inertia for applications with extremely high requirements for synchronism and control quality.

The AM8700 motors combine the advantages of the highly dynamic AM8000 servomotors with the high requirements of the packaging and food industries.

The AM8800 motors are ideal for extremely harsh environmental conditions. The highest protection rating and stainless steel surfaces defy aggressive media.

The AM8100 motors are specially designed for operation with the compact drive components in the smallest of mounting spaces.

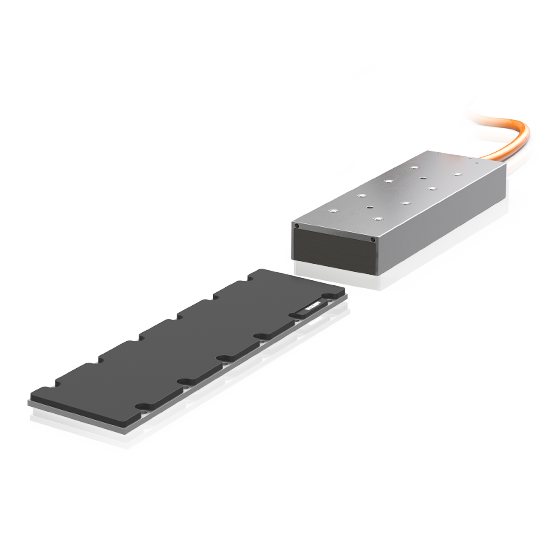

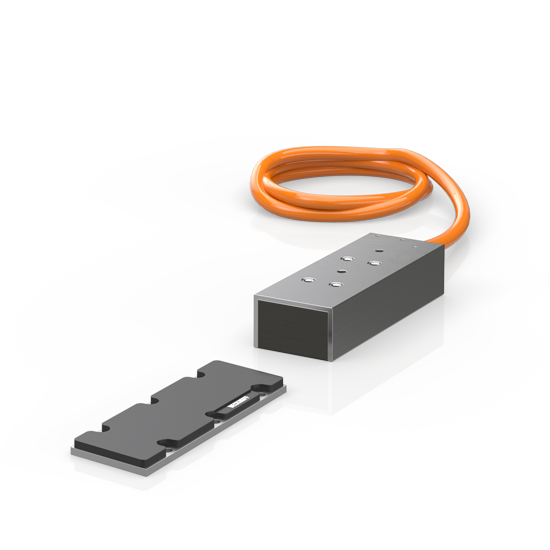

The AL8000 motors are characterized by a modular coil concept and the extremely high force density generated from it.

The AL8100s are characterized by a modular coil concept and the extremely high force density that they generate from it for compact drive technology.

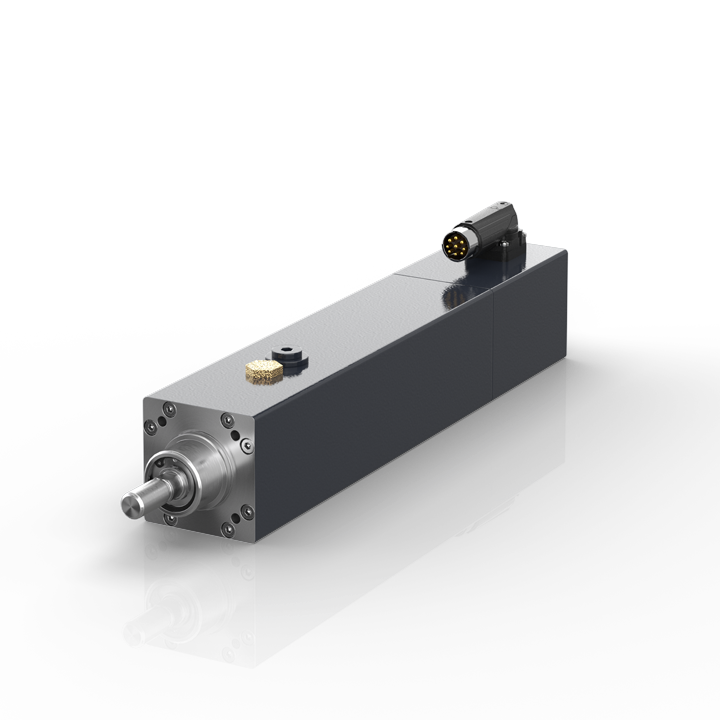

The AA3000 are powerful spindle drives replacing pneumatic or hydraulic drives, optionally with holding brake and other spindle pitches.

The AA3100 are powerful spindle drives replacing pneumatic or hydraulic drives for compact drive technology, optionally with holding brake and other spindle pitches.

The EtherCAT Terminals from the EL/ED7xxx and ELM7xxx series enable the direct connection of various drive technologies.

One Cable Automation facilitates efficient and optimal cabling for devices, machines, and systems.

The one cable solution – One step closer to automation without control cabinets.

The continuous development of the industrial control panel connection technology allows the control panel to be located away from the PC.