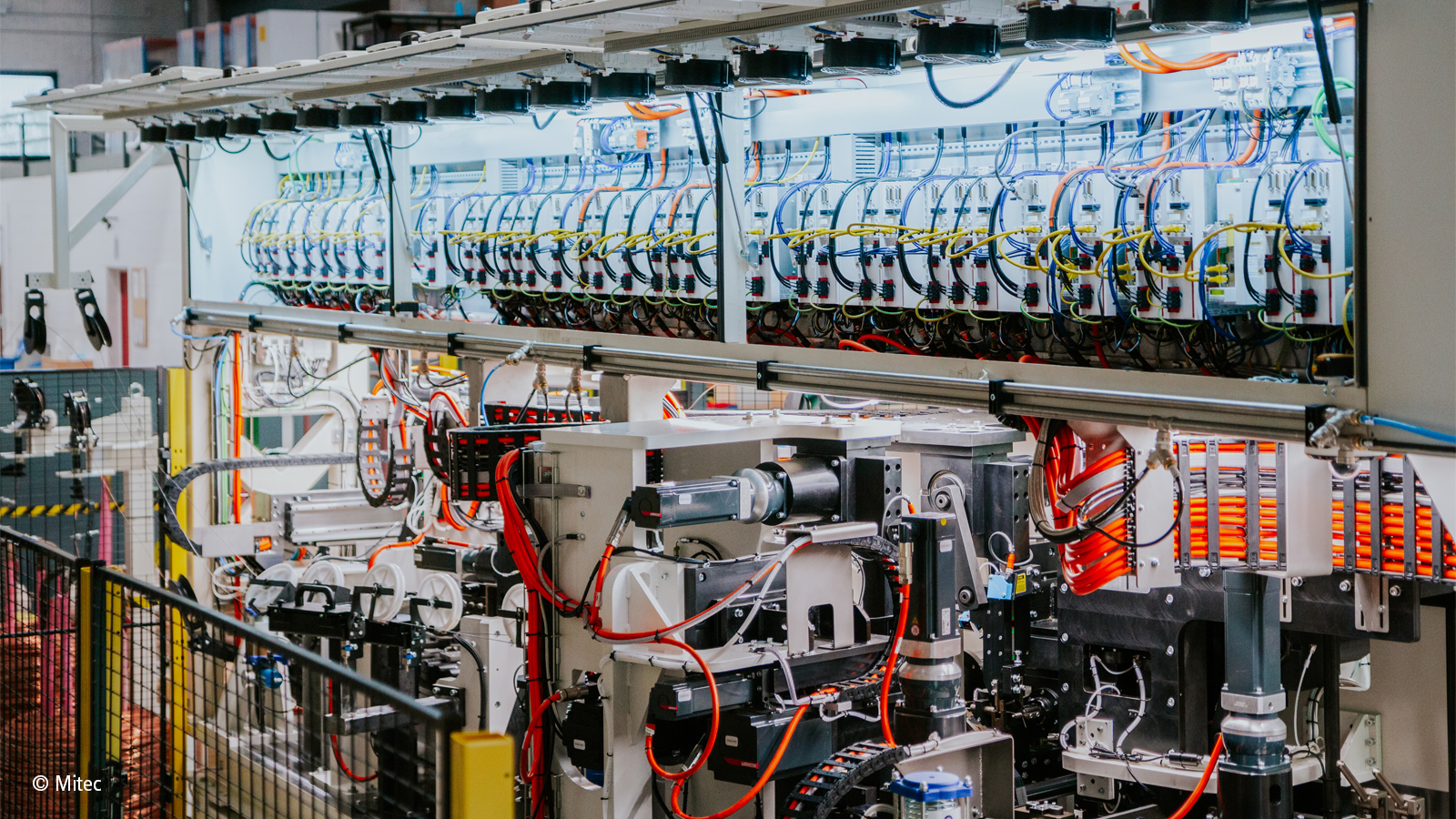

Sophisticated, highly efficient production line through PC- and EtherCAT-based servo drive technology

Mitec Enginy, a young and dynamic automation integrator based in northern Spain, says it has developed a sophisticated and powerful production technology masterpiece. The core element is a revolutionary motion control system with a total of 67 servo axes synchronized by camming function. The result is a production line that feeds, cuts, and bends wire, produces springs, and mass-produces the final product – a rat trap – in just 1.5 s. In addition to the servo drive technology, Beckhoff also supplies the required control performance with the CX2062 Embedded PC and TwinCAT software.

Mitec Enginy has been developing and integrating application-specific automation systems for customers around the world since 2006. In its own words, the engineering company continuously focuses on innovation in the automation of industrial processes, the modernization of a wide variety of machines, and the implementation of comprehensive solutions. Managing Director Albert Gratacos confirms this: “We constantly strive to keep up with the latest technologies in order to offer our customers the most appropriate solutions for their automation problems, and our close cooperation with Beckhoff is one of the most fundamental elements in this regard.”

Servo drive technology replaces mechanics

“Looking back at the history of automation, it is essential to appreciate the foundations that are simply taken for granted today,” notes Albert Gratacos. He continues, “Eighty years ago, mechanically driven machines were quite common, often powered by a motor and connected by gears, crankshafts, and cams. These inventions still drive our innovations today, yet these machines predate 3D CAD, CNC machining, and software. With today’s technology, mechanical machine components are replaced by multi-axis servo movements and controlled more reliably and flexibly by software.”

The latest project, the rat trap machine, reflects exactly this, as described by Albert Gratacos: “The customer needed to modernize their product manufacturing to remain competitive, so we devised an appropriate way to do that. At first, the idea of precisely synchronizing around 70 servo axes sounded almost crazy, but it ultimately proved to be the right solution for the complex process sequences, and we were able to implement it using PC-based control from Beckhoff.”

A CX2062 Embedded PC serves as the central controller, along with 61 AX51xx and AX52xx servo drives, and 67 AM80xx servomotors. In terms of software, TwinCAT 3 with the camming function (TF5050 TwinCAT 3 NC Camming) ensures precisely synchronized motion sequences. In addition, all necessary safety functions (STO, SOS, SS1, and SS2) are implemented directly in the automation system with TwinSAFE and Safety over EtherCAT. Lluis Moreno, sales engineer at Beckhoff Spain, adds: “This is a very advanced machine featuring the latest automation technology. It is fully equipped with powerful servo drive technology networked via EtherCAT, and can be reliably coordinated with the CX2062 from just one computer.”

Complex solutions require a strong team

According to Albert Gratacos, Mitec Enginy’s success can also be attributed to the team that has been created to develop complex automation solutions: “We handle all of the mechanical and electrical design, programming, and assembly of the automation in-house. At the same time, we recognize that no one person can be the expert for the entire automation system, which is why we have specialists in mechanics, electrics, and programming working closely together to develop innovative automation solutions. But the team at Mitec Enginy doesn’t just stop with our employees; we also consider customers and suppliers like Beckhoff to be project partners and part of the Mitec team.”

The importance of intensive and trusting collaboration is also confirmed by Lluis Moreno: “Mitec Enginy is a long-standing partner of Beckhoff Spain, with whom we have already implemented a number of very different and complex customer projects – often in a very special way. But I have to admit that the current production line is the most efficient and ‘beautiful’ machine in terms of design so far. Each of the many movements is just so fast, precise, and smooth that no unnecessary stresses are transferred to the mechanics of the machine.”