Edge device with Beckhoff

Fast and optimized data processing

Sede centrale Svizzera

Beckhoff Automation AG

Fast and optimized data processing

With its open system, Beckhoff makes it possible to meet specific requirements using toolboxes and functions from the TwinCAT modular system. This also applies to existing system infrastructures that are not based on Beckhoff products. This means that existing customer programs, for example, can be operated in parallel on the host system or simply integrated into TwinCAT. The same concept is found in edge computing – supported by Beckhoff’s long-established and industry-proven industrial PCs, customers are able to configure an overall system that meets their specific requirements.

The following section explains everything you need to know about edge computing and describes the possible Beckhoff solutions for your edge computing project.

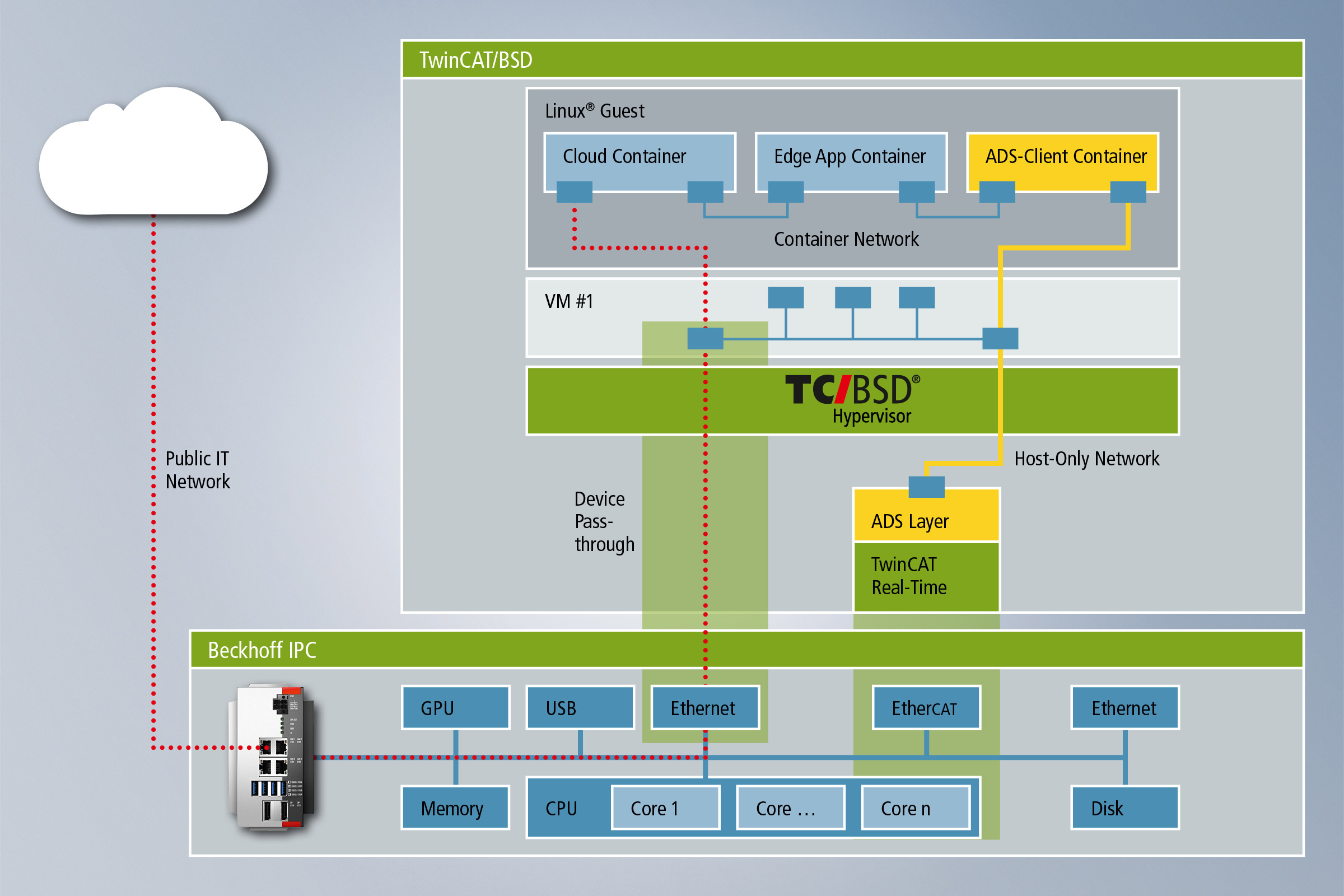

Edge applications are increasingly being developed to run in Linux® containers. For execution, the edge device must provide a Linux®-based operating system and software for managing Linux® containers (e.g., Docker®, Podman, etc.). Through the integrated Hypervisor, TwinCAT/BSD enables the execution of Linux® operating systems in virtual machines on the control system. Containerized edge applications can be operated directly on the control system, providing easy access to its data points. At the same time, the virtual machine creates an environment where the Linux® environment is isolated from the control system, increasing the security of the overall system.

As shown in the graphic, Linux® containers can be connected flexibly to the network. A dedicated host-only network provides access to machine control data points through Linux® containers. Unencrypted communication takes place in a virtualized local network between the TwinCAT/BSD and the Linux® container host. This means that machine control services do not have to be provided on physical ports of the industrial PC.

If a public network connection is also required for deploying Linux® containers or sending data to the cloud, dedicated Ethernet interfaces can in turn be explicitly made available to a Linux® virtual machine through device passthrough. Combining the host-only network, container network, and Ethernet device passthrough creates defined communication channels between the public IT network, edge applications, and the control system.

Existing, older machines often lack modern connectors to connect them to a cloud or to pre-process data, for example. However, edge devices can be used to easily convert older machines or their controls to the state of the art, enabling them to support modern protocols such as MQTT, OPC UA, or data formats like JSON. Data can be formatted, manipulated, interpreted, or filtered directly on the edge device and only selected data strings need to be exchanged with the cloud. This also helps to maintain streamlined, efficient, and fast cloud storage and can reduce the necessary bandwidth.

Depending on the variant, EtherCAT or bus terminals can be connected to the edge device to equip the machine with additional sensor technology at a later date and to retrofit the machine with a condition monitoring function if the edge device is also intended to manage PLC functions. If the old machine is already equipped with a Beckhoff control, it does not need to be adapted further; only data of interest is forwarded via ADS to the edge device for further processing. The edge device can also be used to access the machine via WLAN or mobile communications. Customers can then use a mobile phone or tablet to connect to the machine and to display important production data directly on site.

Edge devices can collect data from multiple machines with Beckhoff controls, legacy controls, or even proprietary systems. The edge device then manages the local pre-evaluation and aggregation of machine data, allowing critical thresholds or production data to be processed quickly. The data can be stored on site, visualized directly on the edge device, and also transferred to higher-level cloud or database systems. Further physical interfaces such as USB, DVI/DisplayPort, RS232, etc., are also available depending on the edge device features.

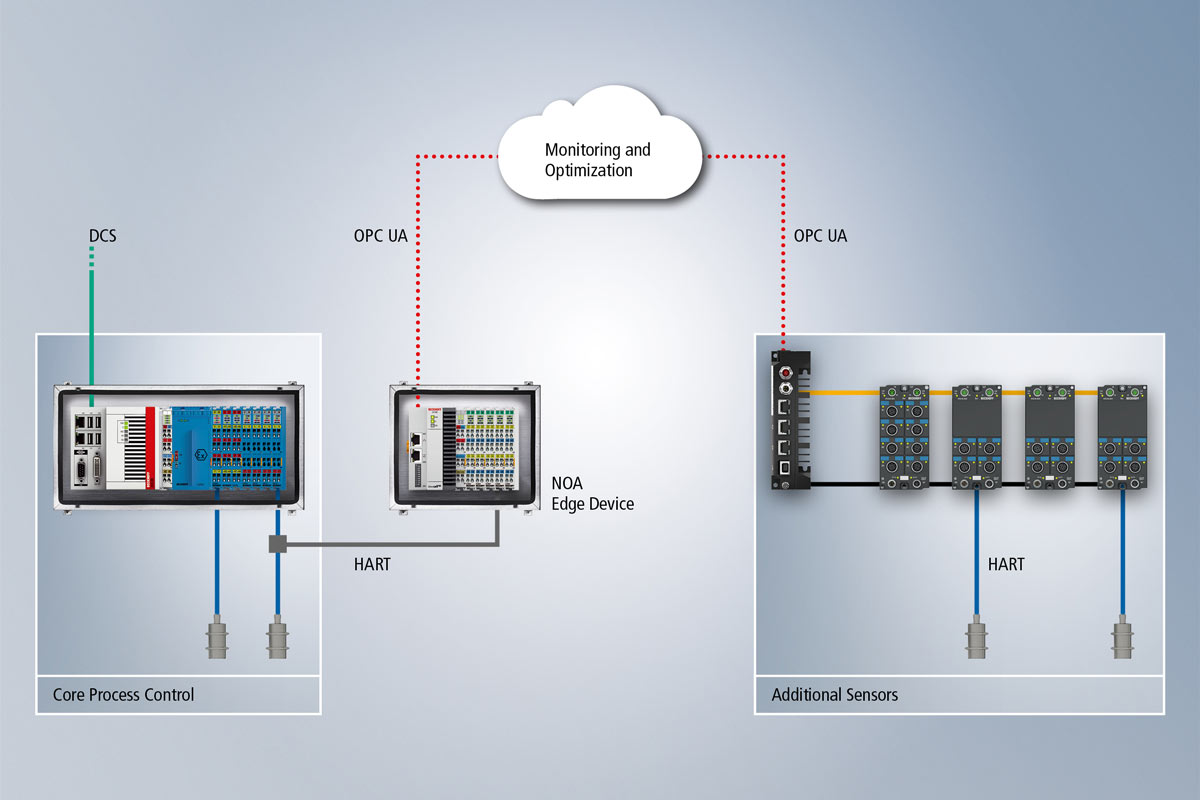

Central monitoring and analysis is of enormous importance, especially in the process industry. For new and existing plants, it is important to collect all operating data and make it available to various applications. This data is evaluated in analytical tools to enable failures in field devices to be detected at an early stage, for example.

However, the implementation of IoT concepts is particularly challenging in established process technology plants, as the necessary information from the field devices is not captured in the existing automation architecture. The User Association of Automation Technology in Process Industries (NAMUR) therefore devised the NAMUR Open Architecture (NOA). The concept described in NAMUR Recommendation NE175 extends the automation architecture without altering the existing control system.

Beckhoff has therefore developed an NOA edge device specifically for reading out the additional operating data for higher-level analytical tools. The edge device, which consists of a compact embedded PC, EtherCAT Terminals with HART functionality, and the relevant TwinCAT project, can be placed directly in the plant.

Energy management now plays a very important role in the operation of production facilities. Edge devices can provide retrofit support for legacy controls or with regard to energy management – the necessary terminals can be easily connected to the Beckhoff Embedded PCs and Industrial PCs to retrofit current transformers and voltage monitoring systems.

Current and past energy consumption can be visualized directly on the device or transferred to the cloud. Evaluations can be triggered and processed when ISO 50001-1 certification is required. On the software side, the TwinCAT Analytics platform offers a construction kit to support this use case.

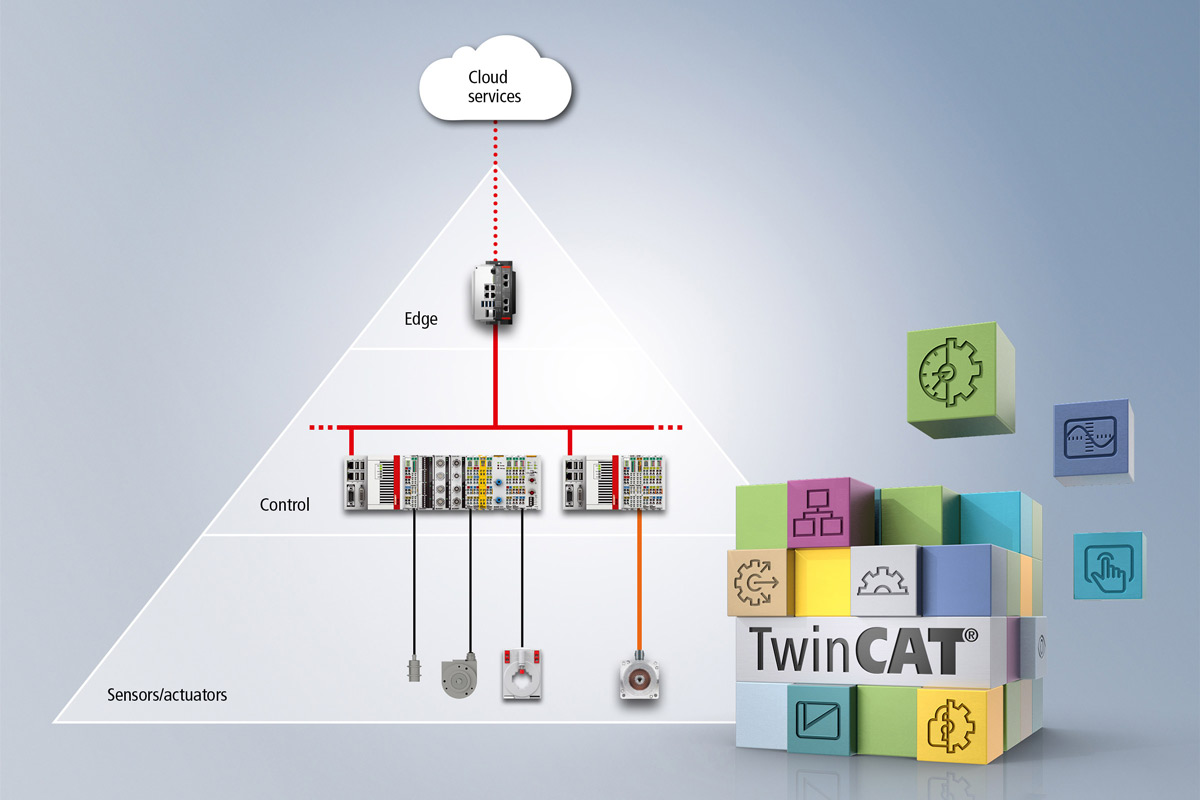

Cloud connectivity is a key feature of many Beckhoff products. Connectors for various cloud-based web services have been part of the portfolio since 2015. The first application experiences in connecting TwinCAT systems to the cloud even go back to 2011. The “from sensor to cloud” concept is therefore available at all levels.

It is possible, for example, to connect current transformers and actuators of any type to the embedded PCs via EtherCAT Terminals, to pre-process, filter, and visualize the data at the control level, and to then transfer it on to a higher-level edge device via Ethernet. At this level, pre-processing, in-house containerized applications, and other third-party products can also be operated on industrial PCs in order to transfer the right data for the application in question to the cloud for use.

In principle, individual products can be combined and used at any level of the communication pyramid. TwinCAT 3 offers both full flexibility as well as a modular system from which customers can select and design their application as required. This enables them to perform all the necessary steps for creating new applications or for integrating existing software and hardware “from the sensor to the cloud” using Beckhoff hardware and software.

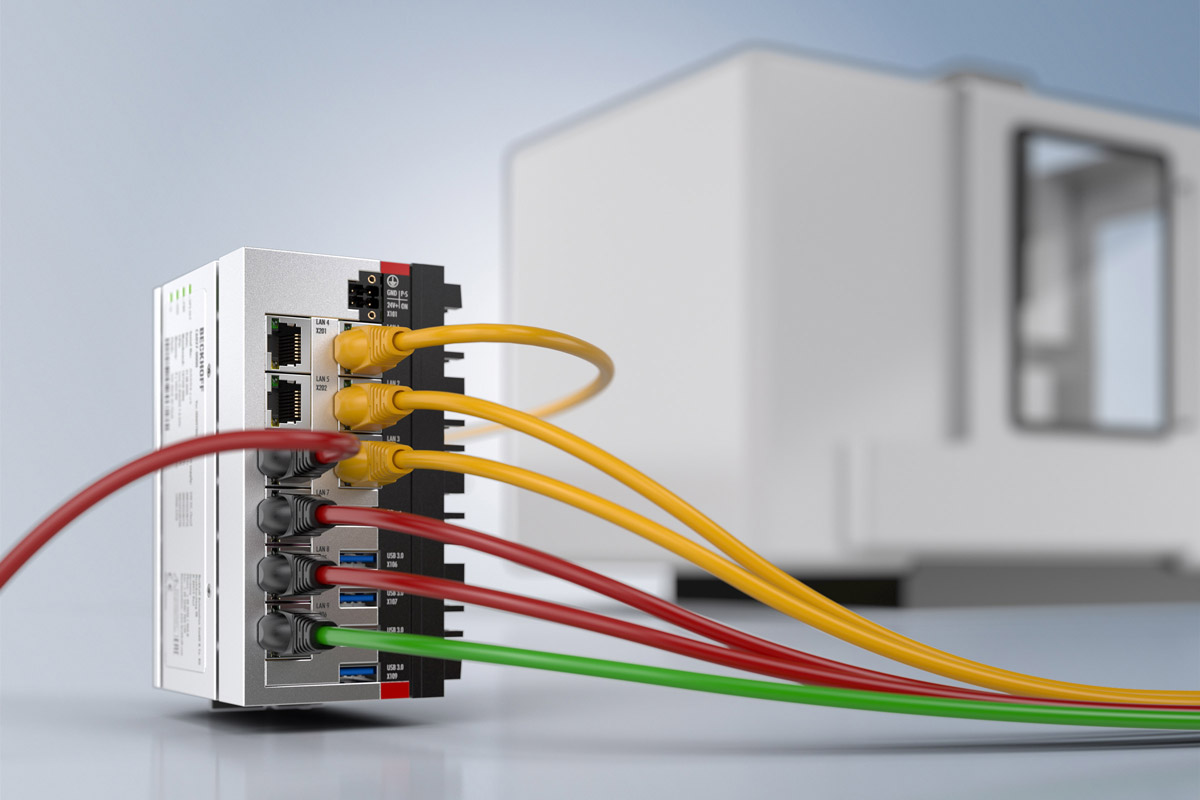

The scalable C60xx series combines maximum computing power in what is currently the most compact format with a wide range of options for installation in the control cabinet.

With the CX series of Embedded PCs, Beckhoff has combined PC technology and modular I/O level to form a space-saving DIN rail unit in the control cabinet.

Beckhoff offers a machine learning (ML) solution that is seamlessly integrated into TwinCAT 3.

The TwinCAT Analytics product family offers a complete workflow for data acquisition, storage, analysis and visualization in dashboards.

The TwinCAT 3 HMI Server is a modular web server that provides the human-machine interface (HMI). It supports all CPU classes from Arm® to multi-core. The powerful architecture enables a wide range of application scenarios from local panel solutions to multi-client, multi-server and multi-runtime concepts.

OPC UA is a platform-independent, service-oriented communication architecture for reliable, secure and multisupplier data transport from the production level to the production planning and ERP system or to the cloud.

TwinCAT 3 OPC UA Pub/Sub extends the OPC UA client/server architecture to include publisher/subscriber communication patterns. The TF6105 TwinCAT 3 OPC UA Pub/Sub provides the necessary implementations of the protocol so that these kinds of communication patterns can be readily integrated into the TwinCAT application. It includes various transport protocols as defined in the corresponding OPC UA specification part (OPC10000-14), e.g. UDP and MQTT.

TwinCAT 3 offers a wide range of options for connecting TCP/IP-based third-party systems to the control program: OPC UA, MQTT, HTTPS, and Modbus are just a few familiar examples from a large number of communication protocols. The TwinCAT S7 communication function extends this wide range further through the S7 communication protocol.

TwinCAT 3 IoT Communication provides basic functionalities in the form of PLC libraries for sending and receiving data via the so-called MQ Telemetry Transport (MQTT) protocol.

The TwinCAT 3 IoT Data Agent provides bi-directional IoT communication functions in the form of a gateway application that can be configured and operated independently from the TwinCAT real-time environment.

So-called REST (Representational State Transfer) APIs are frequently offered by web servers in IoT communication in order to channel certain communication processes via a uniform and stateless interface. REST APIs can be used, for example, to query weather data, to communicate with messenger services or as an interface for writing to a database.

The IoT product portfolio is extended by the implementation of a WebSocket client, providing a further protocol for communication from the TwinCAT 3 PLC in addition to HTTP and MQTT. The control also features a WebSocket server, which acts as both a WebSocket client and a WebSocket server. The WebSocket protocol is suitable for a bidirectional connection between server and client, and is used in web communication when the server wants to actively send data to the client, such as in live tickers for sports events, support chats, or even messaging services.