Automation solutions for data centers

Zhejiang Dafeng Industry, China

PC-based control showcases Chinese heritage

Automation solutions for data centers

Zhejiang Dafeng Industry, China

PC-based control showcases Chinese heritage

Sede centrale Svizzera

Beckhoff Automation AG

Zhejiang Dafeng Industry, China

Zhejiang Dafeng Industry, China

Anyone whose mind is on sustainability, CO2 savings, and the social responsibility we have to achieve global climate goals has a crucial question to ask themselves: What solutions are available to significantly reduce a large share of global energy consumption – that is to say, energy consumption in buildings? This question is not only an ecological one, it is increasingly also an economic one. Investors and operators have overlapping interests, in that only buildings that have been optimized in terms of energy efficiency and that feature appropriate energy monitoring and energy metering solutions are buildings that are fit for the future.

With building automation across all technical systems – such as we are offering with PC-based control – sustainable, energy-efficient construction and living can be implemented in the sense of a green building. All technical systems are integrated on a single platform. All participants in the building value chain benefit from this: Architects enjoy maximum creative freedom with optimal functional efficiency; specialist planners are provided with increased planning reliability with reduced complexity; system integrators benefit from simplified engineering and increased process reliability; operators minimize their operating costs and maintenance work; investors are provided with the greatest possible investment protection.

Heating, ventilation and air conditioning (HVAC)

With the TwinCAT 3 Building Automation software library, a comprehensive package of function blocks is available for building automation that covers the entire range of functions of the HVAC control. This significantly simplifies the work of the system integrator in the implementation of heating, ventilation and air conditioning technology. Functions such as summer night cooling, summer compensation, backup operation and time schedulers are also available. With the help of the HVAC modules, further energy-saving possibilities can be exploited by the occupancy-dependent control of technical systems.

Room automation

Illumination, solar protection, window control, heating, ventilation, and air conditioning are linked with one another on a central platform in room automation for the intelligent control of all technical systems. This reduces the number of individual physical data points and thus the susceptibility to errors. In addition, the provision of all data in one system is the basic prerequisite for successful energy monitoring. The thermal automation solar protection functions and the lighting solution for daylight-dependent illumination control contribute significantly to energy savings. Classic room control units can also be easily integrated via KNX/EIB, Modbus, and EnOcean.

Media technology

Through support for the common protocols and interfaces of media and building technology, our automation platform is able to address all industry-typical devices and systems. Moreover, the integration of AV and media technology and building automation opens up new possibilities, e.g. for the simple control and operation of multimedia devices in meeting and conference rooms.

Operating and monitoring

Depending on the building type or function, the customer-specific requirements vary with regard to remote maintenance, energy and consumption data acquisition, compressed air monitoring and scheduling, etc. The TwinCAT HMI software is perfectly suited to the visualization of all building control and monitoring data. The visualization can be done on a local panel PC or a control panel connected to an industrial PC or embedded controller. However, any HTML5-capable browser, e.g. on smartphones or tablets, can also be used for HMI visualization. The TwinCAT IoT functions also enable simple and secure communication with cloud services.

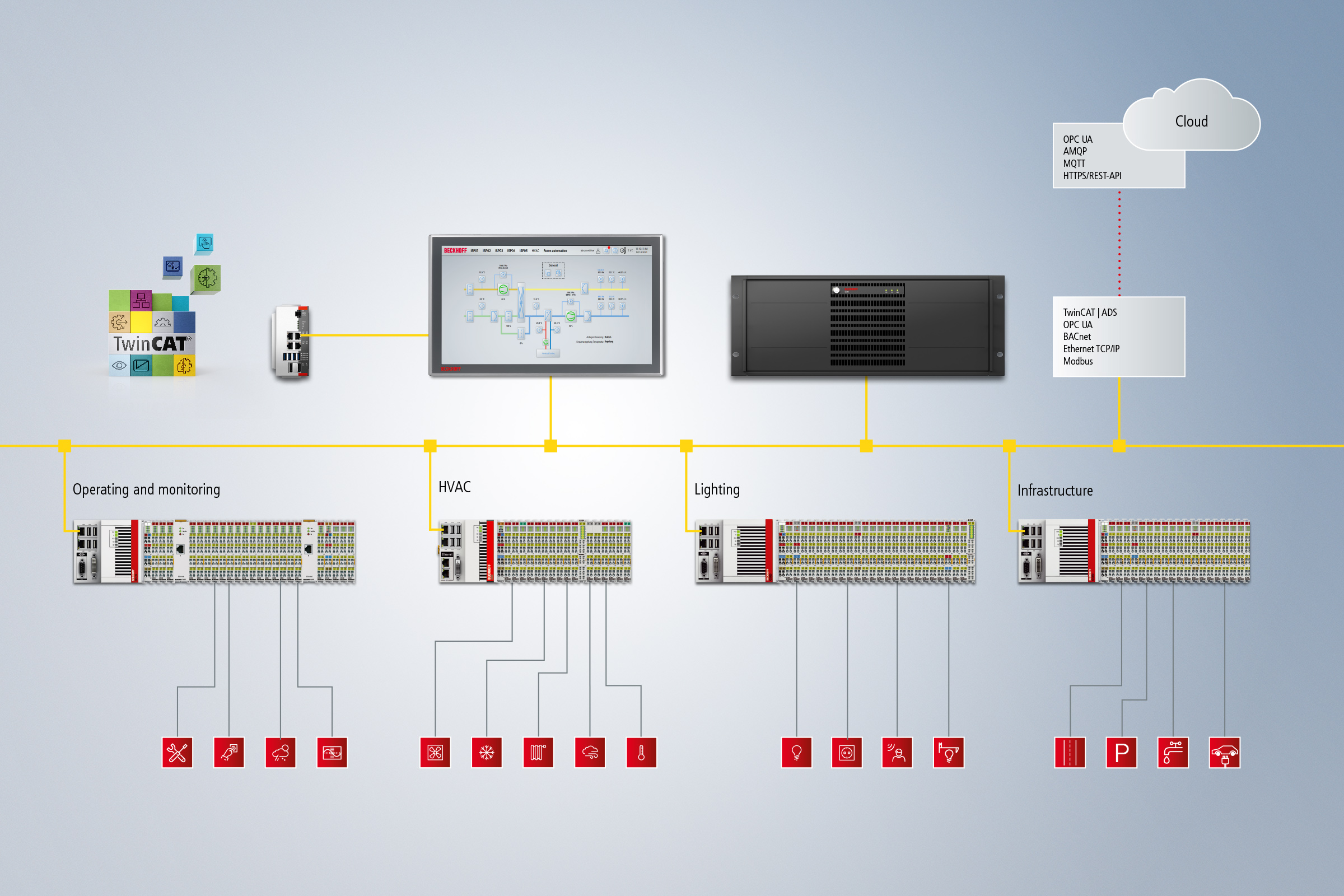

With a comprehensive construction kit of modular and scalable software and hardware components, we offer a made-to-measure control solution for every task in building automation that is precisely tailored in terms of performance, cost and available installation space. The powerful, PC-based automation platform is responsible for control, data processing, connectivity, visualization, remote maintenance, and cloud integration. Due to the open interfaces in software and hardware, it is optimally suited to the central or decentralized control of all technical systems. Control can take place locally or in the cloud.

From the powerful industrial PCs for the management and control level, the embedded PCs for the automation level to the bus terminal controllers for room automation, you benefit from maximally scalable performance. With around 1,000 different I/O terminals, our bus terminal system supports all commonly available sensors and actuators as well as the fieldbus systems typically used in building automation. The fine granularity of the system makes it possible to insert only as many inputs or outputs as the respective project requires. The TwinCAT Database Server can be integrated into project planning to connect the building automation to commonly available databases. In conjunction with the TwinCAT IoT functions, data storage and monitoring can also be implemented in the cloud.

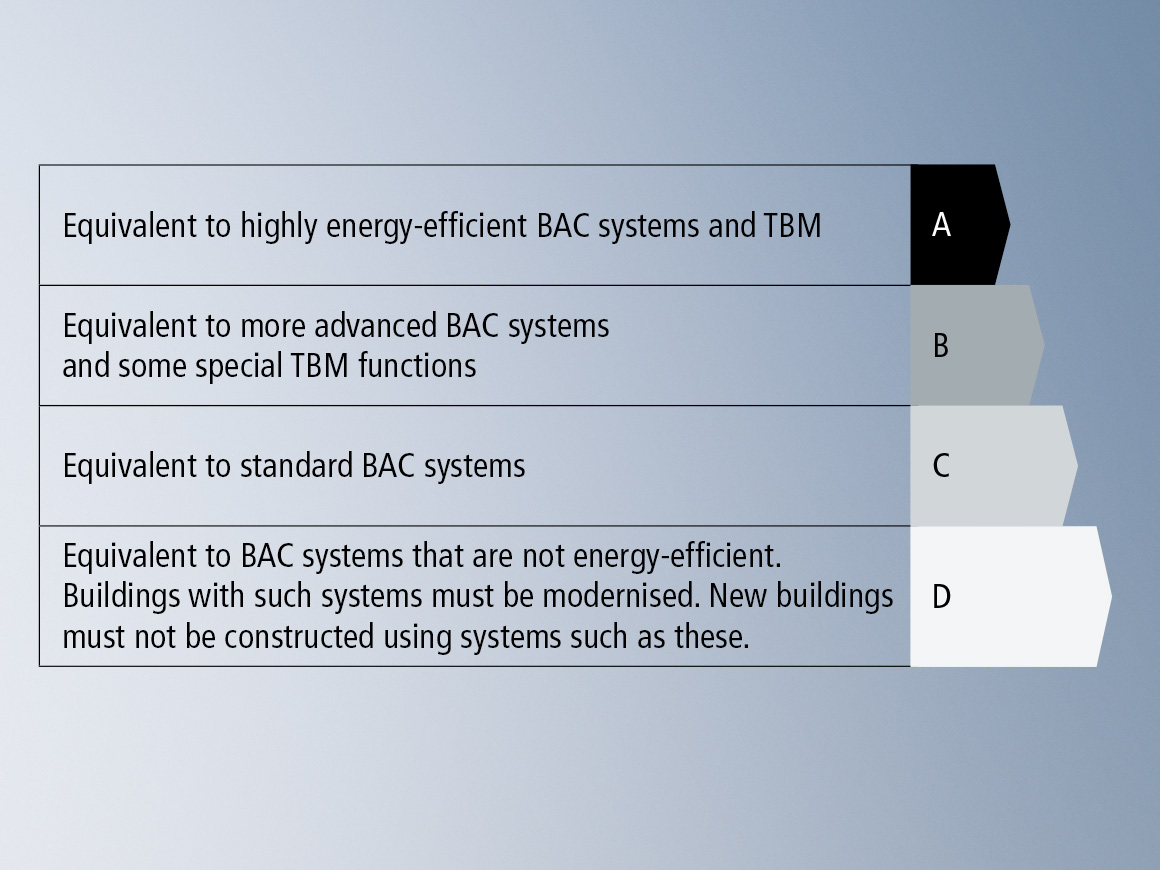

Future-proof buildings must meet diverse guidelines and standards with regard to energy efficiency and sustainability. Automation technology can be used to implement all relevant standards, such as EN 15232. This describes the influence of building automation and building management on energy efficiency and includes a structured list of all building automation functions and their influence on energy efficiency. In addition, EN 15232 provides methodical support for the definition of minimum requirements for building automation. As a general rule, the higher the degree of automation, the higher the energy savings. Energy efficiency class A of DIN EN 15232 is achieved with a PC-based control solution from Beckhoff and the optimized functions in the TwinCAT 3 Building Automation software library. Operators benefit from the ISO 50001-ready status and can be exempted from the energy allocation charge through the recording of all energy consumption.

A high Smart Readiness Indicator can also be implemented with Beckhoff. The standard defined by the EPBD indicates the level of a building's ability to intelligently adapt functions according to demand. For example, a room should only be heated and lit when someone is in it: Sensors detect the presence status and regulate the corresponding building functions automatically. PC-based control makes all the data collected available on a central platform as the basis for intelligent energy management.

Energy data acquisition and management, and the resulting opportunities for optimization, are becoming increasingly important for modern building automation. Cloud systems play a central role in data handling. With building automation from Beckhoff, integrated communication from the I/O level to the cloud can be implemented with TwinCAT IoT functions.

A key benefit of cloud integration is the ability to combine multiple properties into one portfolio. This enables direct comparison of building data and thus performance monitoring as well. Anomalies in energy consumption can be quickly identified and investigated by comparisons with similar buildings. Monitoring and notification of faults can be performed centrally and from any location using devices such as smartphones or tablets. TwinCAT Analytics also enables building data to be analyzed directly in the cloud. The use of databases allows cost-effective storage of data over a long period of time and comparison with rule-based analyses. With predictive maintenance, problems caused by wear or contamination can be detected before failure occurs. Machine learning concepts enable the optimization of operating strategies and control algorithms over the entire operating time and service life.

With the supplements available in TwinCAT (e.g. HTTP/Rest, MQTT or OPC UA), no further devices are required for integration with cloud systems. Communication takes place directly from the TwinCAT control to the cloud. This makes the controllers from Beckhoff perfect for use as edge devices.

PC-based control for building automation in office buildings and educational institutions

PC-based control for building automation in hotels, cruise ships and stages

PC-based control for building automation in commercial and industrial buildings

PC-based control for heating, ventilation and air conditioning

Is a fully autonomous building mere science fiction? No, it is already a reality, as the Belgian ASL Group in Liège is proving with a state-of-theart, 24/7 terminal for private flight operations. Beckhoff Solution Provider Boolean BV supported the implementation of this with end-to-end building automation.

Zhejiang Dafeng Industry is a leading solution provider from China serving the tourism and cultural sectors. When a branch for a national pavillion in Hangzhou was built, Dafeng was contracted to develop an intelligent folding wall system. With its greenish tile surface, the installation resembles a famous landscape painting. In the synchronized movement of the 251 walls weighing several tons each, PC- and EtherCAT-based control technology from Beckhoff ensures functional safety.

The scalability, modularity and reliability of the components make PC-based control from Beckhoff the ideal tool for implementing all building technology applications. Intelligent networking of all applications on one central platform is essential for ensuring optimum functionality and reducing energy consumption.

Whether it’s in a showroom, on a display, or on sales shelves, lighting makes all the difference. The Italian department store group Bennet SpA has extensive experience in this field and is gradually equipping its 73 stores and 45 shopping centers with modern building automation. Established system integrator INTEREL Trading uses PC-based control from Beckhoff and DALI-2 to meet the operator’s requirements for flexible designs to create different lighting environments and high energy efficiency.

In thermal power plants, more than 50% of the energy is usually lost in the form of heat. The natural gas driven power plant at Melbourne Airport, on the other hand, uses the waste heat to generate heat and cooling, thus achieving a much higher energy yield. This is helped by Beckhoff Embedded PCs and EtherCAT I/Os enabling fast control and regulation of the plant, which automatically switches to emergency power supply in the event of a power failure.