TwinCAT Core Boost for greater computing performance in real time

TwinCAT 3 from Beckhoff consistently supports modern multi-core processor technology. The multi-thread capability makes it possible to distribute the application across several cores. Supplemented by TwinCAT Core Boost, the computing performance of individual real-time cores can now also be increased by up to 50 % to maximize system performance and optimize it for specific requirements.

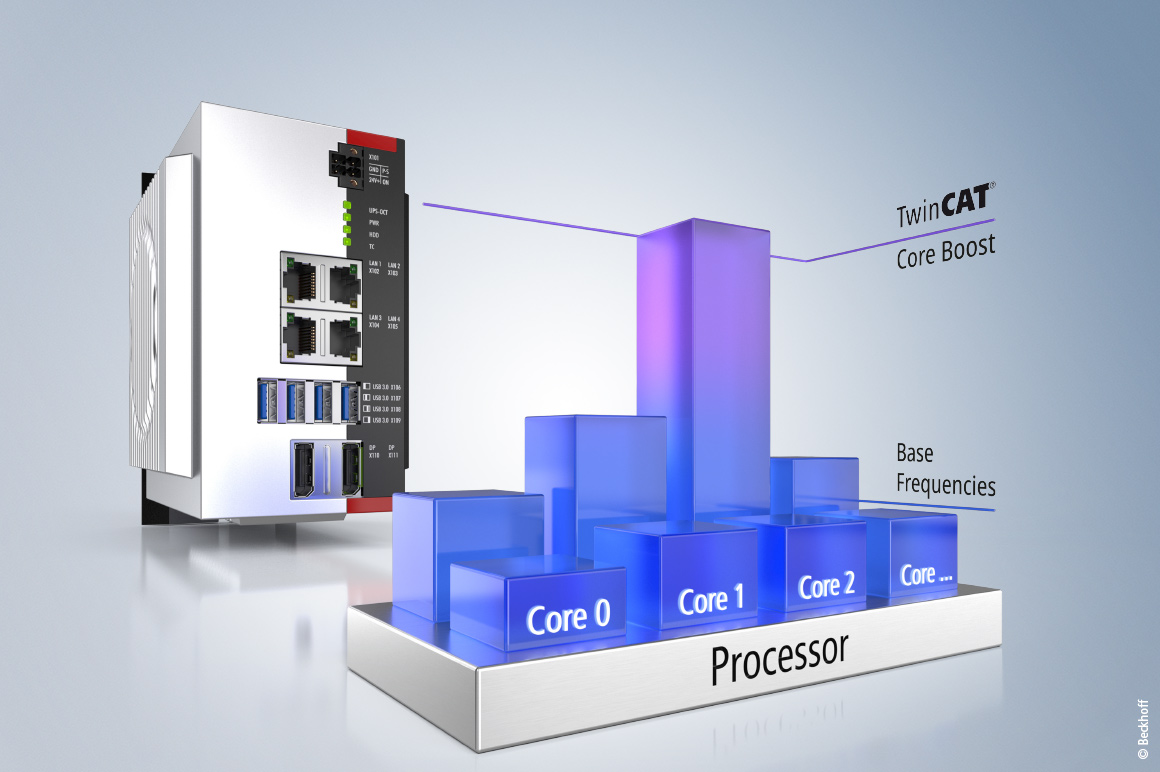

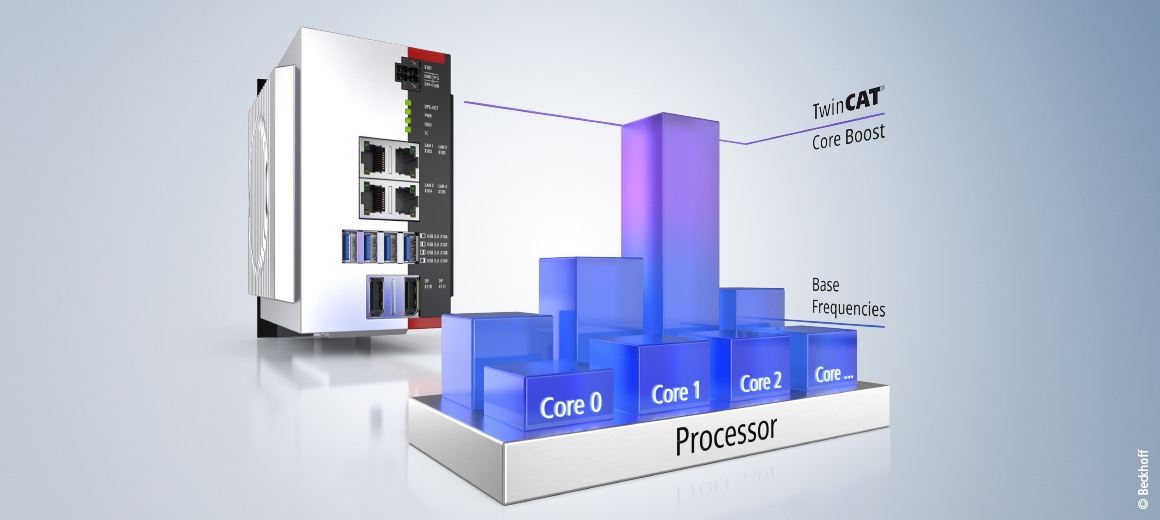

With TwinCAT Core Boost, the clock frequency of the processor cores can be configured individually and as required, so they no longer all have to be clocked at the same rate. The clock rate can be set for each real-time core. It is also possible to operate individual cores continuously and in real time in what is known as turbo mode.

The permissible current consumption and temperature of each processor core (and of the overall system) is monitored by TwinCAT Core Boost, ensuring reliable operation even when the turbo mode is used. TwinCAT Core Boost will gradually be introduced for all Beckhoff Industrial PCs with Intel® Core™ i processors from the 11th generation, initially for the:

and then for:

- C6025, C6027, C6030, C6032, C6040 and C6043 ultra-compact Industrial PCs

- CP62xx and CP72xx or CP22xx and CP32xx single and multi-touch Panel PCs

- C6515 and C6525 built-in Industrial PCs without fans

- C6920 and C6930 compact Industrial PCs

- C6640, C6650 and C6675 control cabinet Industrial PCs

- C5210 and C5240 19-inch slide-in Industrial PCs

Increased control performance and cost efficiency

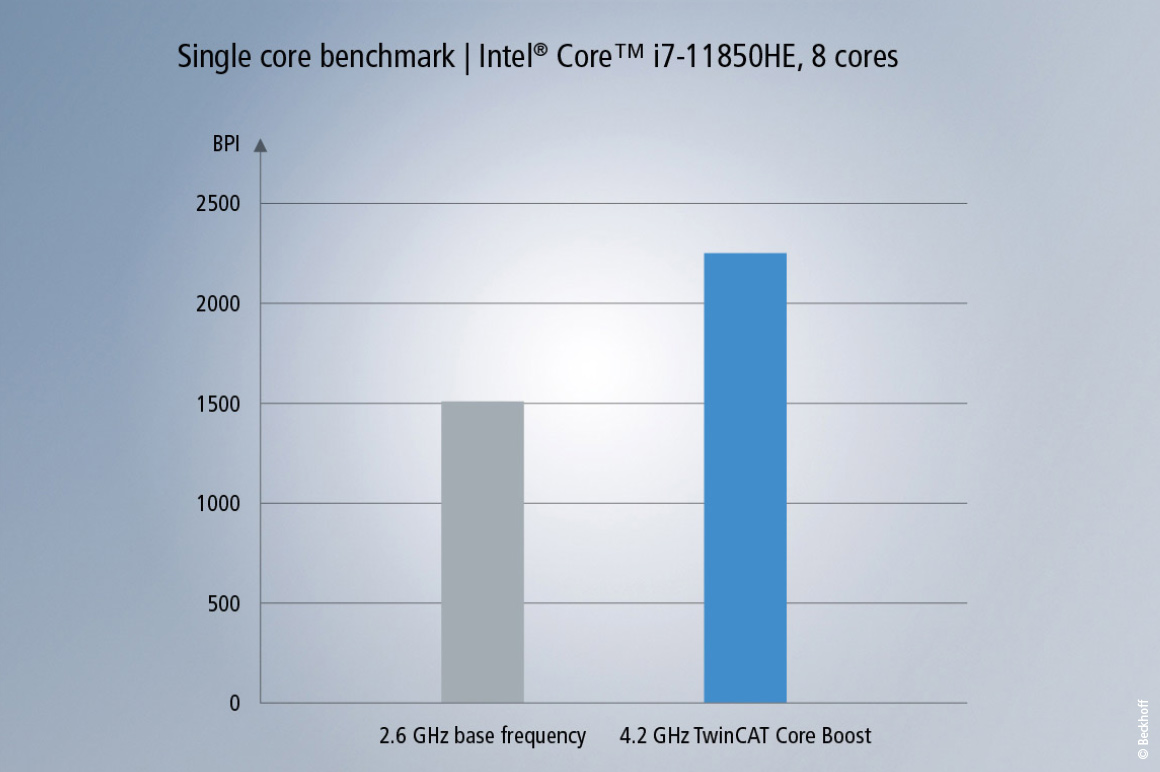

In combined benchmarks for the Beckhoff Performance Portal, the single-core performance of an Intel® Core™ i7 11850HE with base frequency was compared with the same CPU with TwinCAT Core Boost on a single core: With TwinCAT Core Boost, it was possible to increase the clock frequency from 2.6 GHz to 4.2 GHz. This meant the Beckhoff Performance Index of the CPU could be increased by over 50 %. The benchmark is an example of how TwinCAT Core Boost can increase clock frequencies and thus shorten computing times. This makes it possible to minimize project cycle times and operate machines and systems even more efficiently. TwinCAT Core Boost can also be used to elevate smaller processors to meet the performance standards required for the application, which they might otherwise struggle to achieve. Therefore, the user saves costs for both the required hardware and for processor-dependent software licenses.

In concrete terms, TwinCAT Core Boost enables users to boost the clock rate of individual cores using simple parameterization. This allows them to respond flexibly to the application requirements and efficiently execute application parts with particularly high performance requirements – such as for motion control, a vision solution, or a machine learning model – on the corresponding processor core. The core clock is permanently increased to guarantee real-time capability and deterministic control within TwinCAT. This was made possible by the corresponding features of the new Intel® processors, which now enable users to access, influence and constantly increase the clock frequency directly from the application. It also counteracts the current technological trend toward an increasing number of processor cores that are, however, running at a comparatively low clock frequency.

This further development in processor technology corresponds exactly to the concept of PC-based control technology from Beckhoff which seamlessly integrates all advantages of the IT world into automation technology. As a central control system, the IPC is continually opening up new possibilities and an increased range of functions, including through machine learning or the new TwinCAT MC3 motion control generation. This is because, for example, previously used control code can be executed more quickly on the same platform. What’s more, the IPC can also be used cost-effectively in existing applications, for example by reducing the required processor from an Intel® Core™ i7 to an Intel® Core™ i3. The same code can be executed on a smaller platform at the previous speed, which means users get the same functions at lower costs for hardware, operating system license and TwinCAT performance level.

Integrated in the new TwinCAT Build

The Core Boost function is available as a feature directly integrated in the new TwinCAT Build 4026. On the engineering side, there are the necessary extensions within the existing processor core configuration. Detailed and easy-to-use diagnostic options are also available within the runtime. All the important values can be tracked and questions answered both in the PLC and via the HMI: Does the operating system have sole use of the core or does it share it with TwinCAT? Does TwinCAT run isolated on a core? How high is the overall power consumption of the processor and how warm are the individual cores? All this information is captured in TwinCAT and is accessible for monitoring. TwinCAT responds independently to certain limit specifications. For example, when the maximum permissible processor power consumption is reached, the clock frequency of the non-real-time cores is automatically throttled as a first measure to ensure that the overall system can continue to run stably.