Flexible, floating, low-maintenance

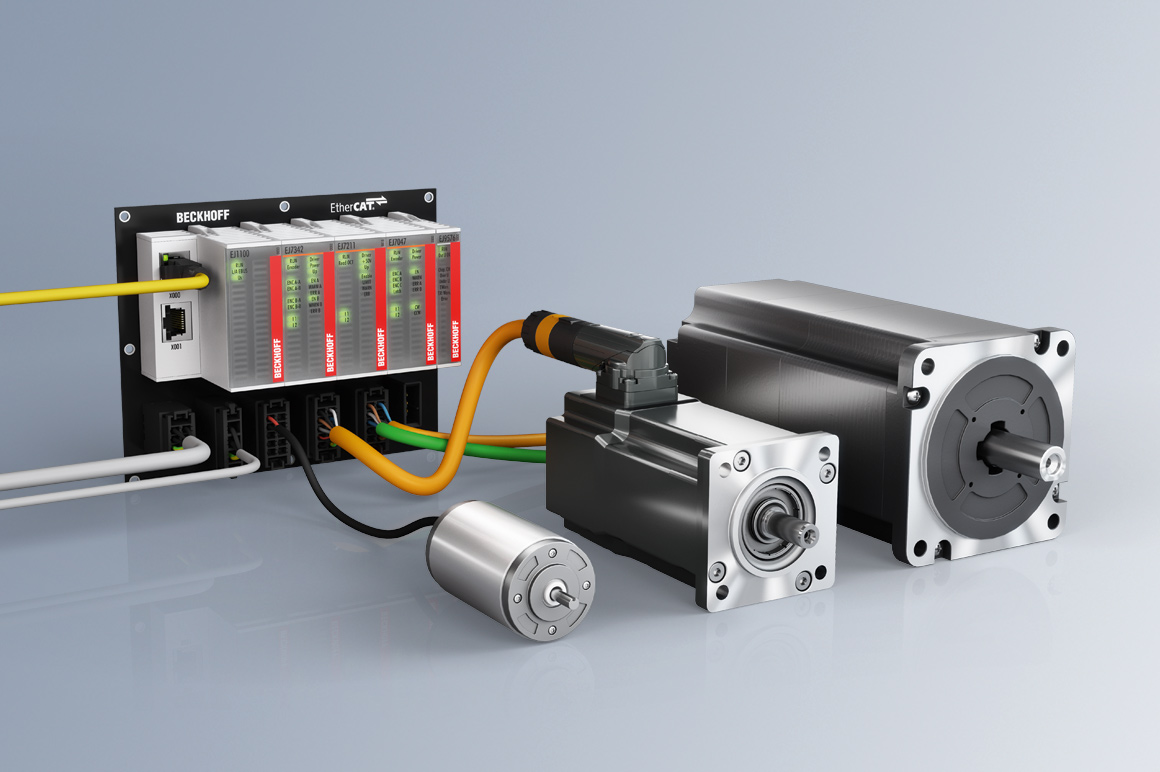

XPlanar, the eXtended planar motor system from Beckhoff, is revolutionizing handling processes in the semiconductor industry. With XPlanar, your production parts can be transported within a tool as well as from machine to machine in a free-floating solution: It is dynamic and jerk-free while offering maximum accuracy and unprecedented freedom of movement.

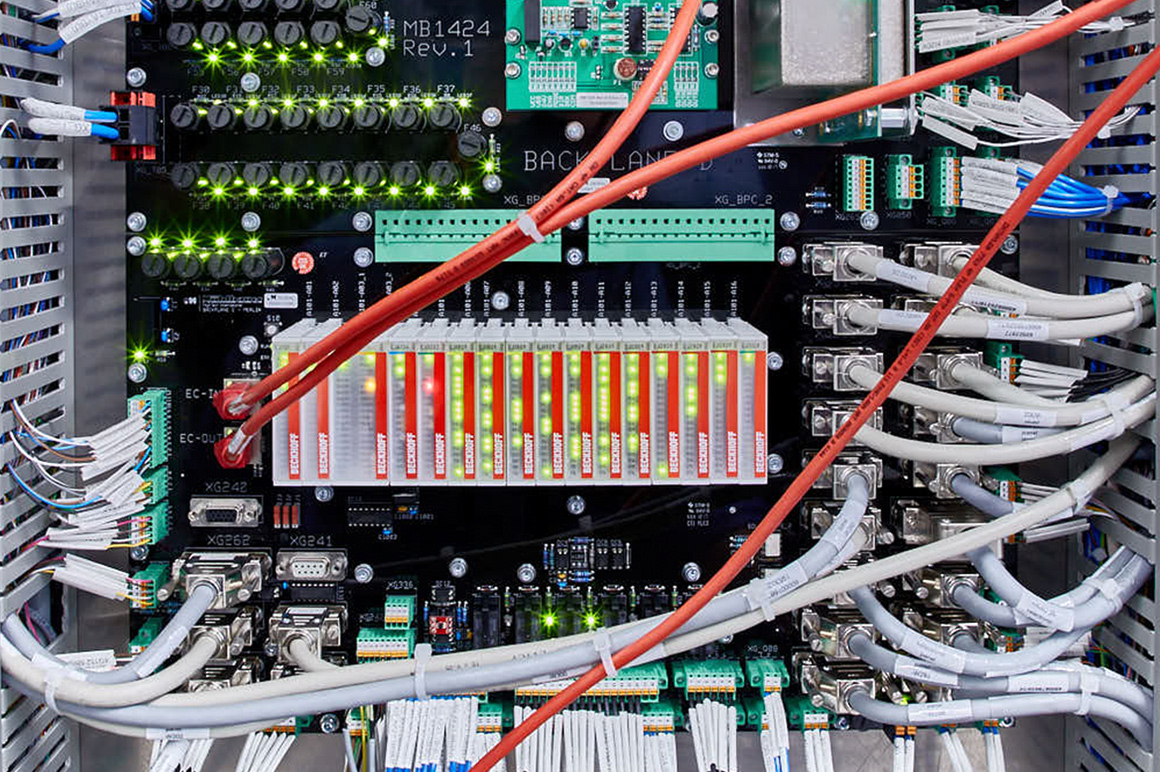

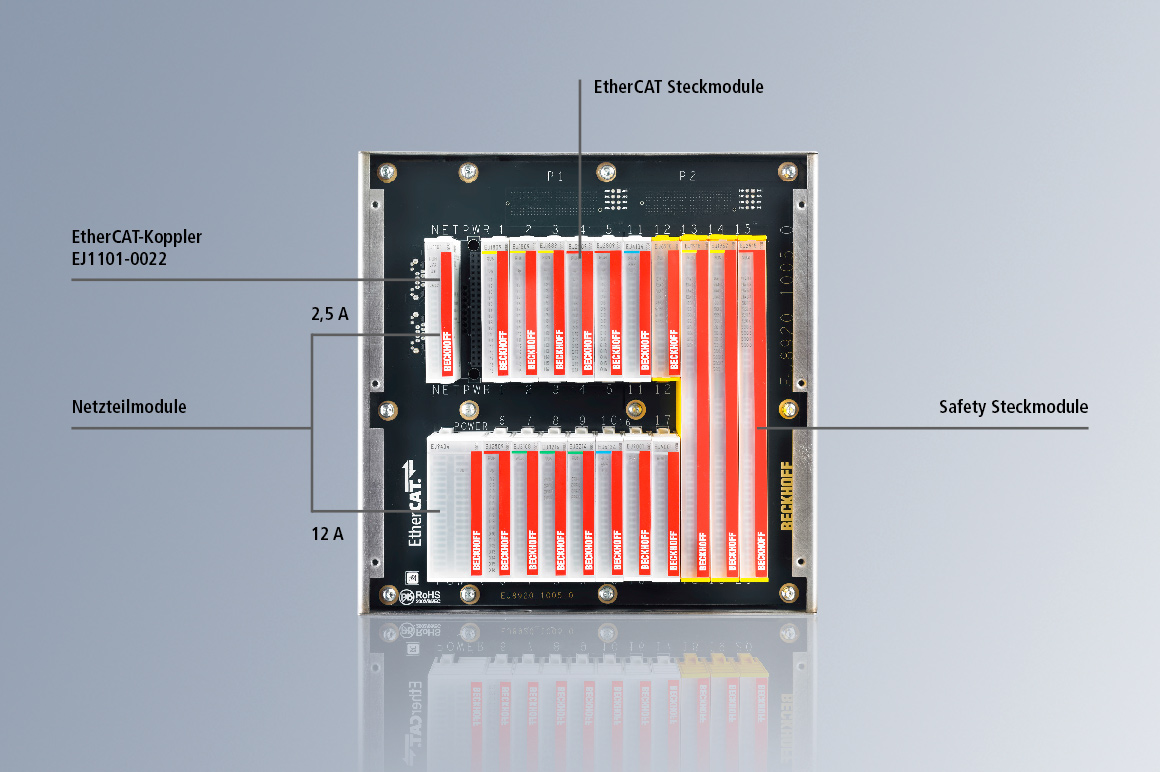

The functional principle is as follows: XPlanar consists of flat, stationary coils, the XPlanar tiles, and moving permanent magnets. The latter serve as object carriers and are called movers. The movers float in a non-contact way over the individually arranged tiles and transport your products to the next station. The movers move independently of one another: Products may overtake each other and be discharged or buffered without affecting the production flow. What’s more, XPlanar requires no mechanical components at all: There are no guide rails, rollers, or lubrication systems. This reduces the time and costs required for maintenance and cleaning to a minimum.

How you benefit from XPlanar:

- free-floating movers for jerk-free part transport at up to 2 m/s

- planar tiles for the implementation of any geometry

- flexible part transport with no rigid station sequences