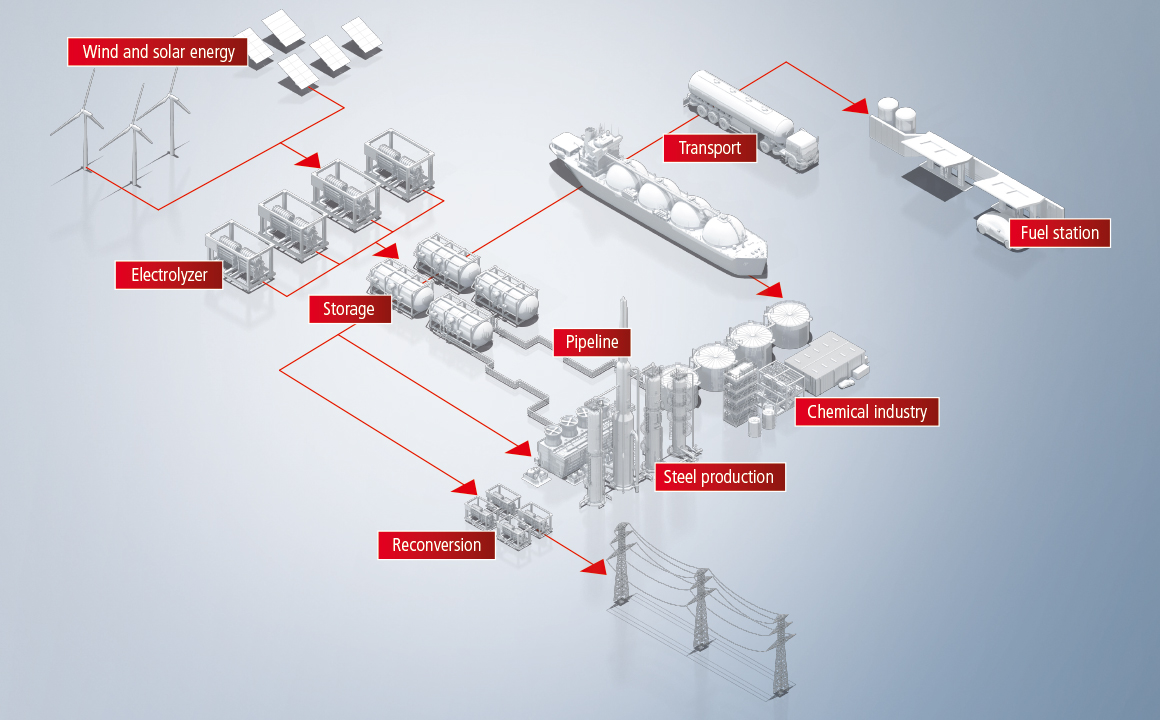

Green hydrogen is one of the key elements for the successful implementation of the energy transition. Electricity generated from wind energy, hydropower, or solar energy can be converted into hydrogen by electrolysis and stored in tanks, transported, and used anytime, anywhere. Energy from renewable sources can be stored using hydrogen and fed back into the grid when needed. PC-based control from Beckhoff can be used to automate a wide range of applications relating to the production, storage, transportation, and use of hydrogen. Precise measurement technology, which is used to monitor electrolysis processes and the safe storage of hydrogen, for example, often plays a special role here.

Voltage measurement – cell by cell and across the entire stack

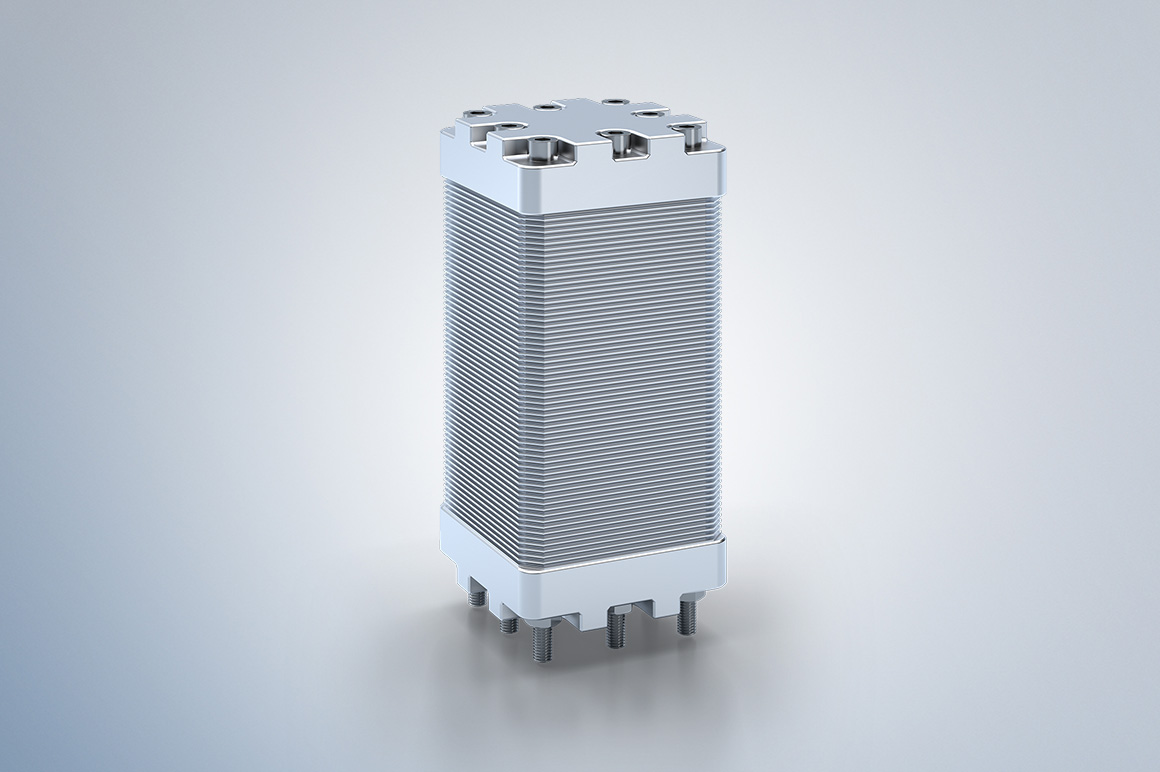

Hydrogen is produced by electrolysis, in which water is split into the elements hydrogen and oxygen by means of electrical energy. A typical industrial electrolyzer consists of several electrolysis cells.

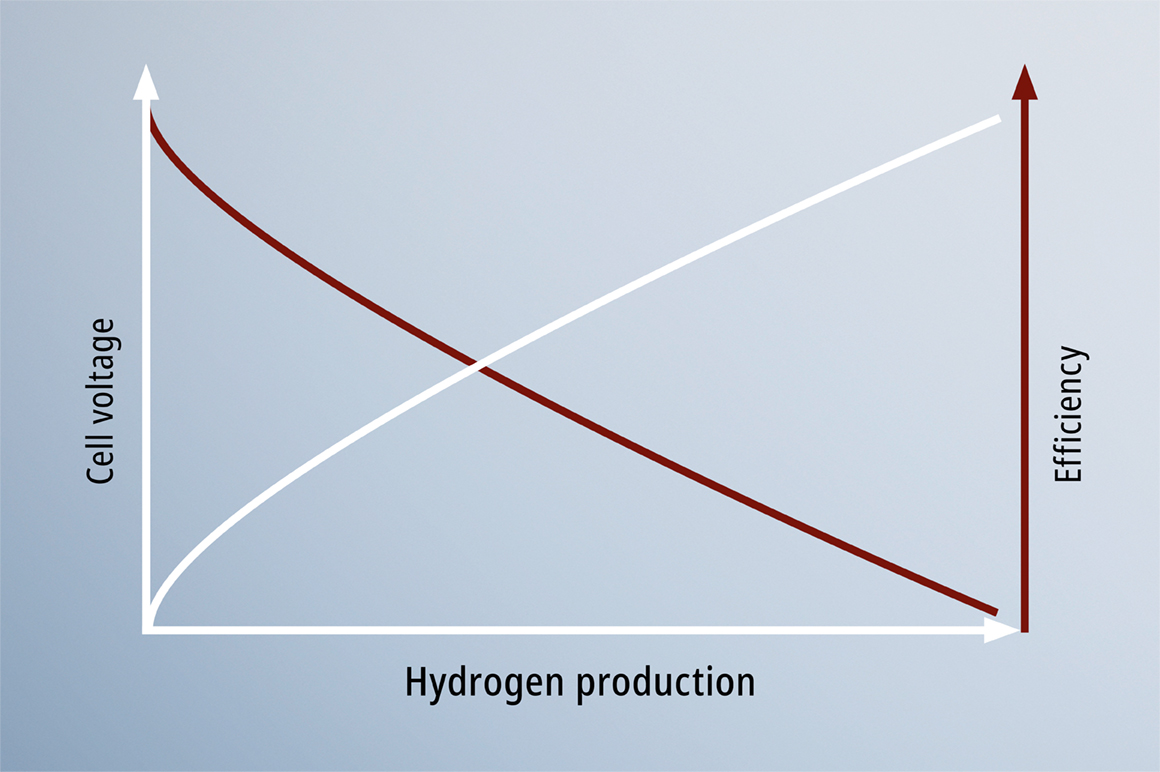

During the electrolysis process, it is essential to measure or monitor the current-voltage characteristic of the individual cells: the cell voltage is directly related to hydrogen production.

If the cell voltage is increased, this results in a higher current density and therefore also increased hydrogen production. This is contrasted with reduced efficiency. Accurate monitoring of all parameters makes it possible to select an optimum operating point. However, the installation position of the cells in the stack means that the voltage can only be set for the entire system. Having said that, the individual cell voltages can take on different values and drift over the service life of the electrolyzer. Due to this, unknown operating points occur, which result in either reduced efficiency or a reduced service life. In order to detect these drifts at an early stage and initiate appropriate maintenance intervals, it makes sense to measure the individual cell voltages.

The EL3008-0003 EtherCAT Terminal offers a solution here: it has eight voltage inputs with ±3 V and can record all relevant parameters quickly and highly accurately during the electrolysis process thanks to its resolution of 16 bits, 2 ksamples/s, and ±0.1 %MBE. The cascaded measuring principle of the terminal significantly reduces wiring work and the high level of insulation allows operation up to a total stack voltage of 1000 V. This means that the terminal can also be used for large systems. Thanks to the modular concept, the terminal can be used both for test set-ups and for permanent long-term monitoring in combination with the entire plant control system.

The EL3002-0205 EtherCAT Terminal is highly recommended for use with this terminal for measuring the total voltage with up to 10,000 measured values per second. This terminal can cover a voltage range of up to 1200 V in high resolution (24 bits). This provides operators of hydrogen electrolyzers with an up-to-date overall picture of the processes and enables them to optimize the operating point and respond quickly in the event of a malfunction.

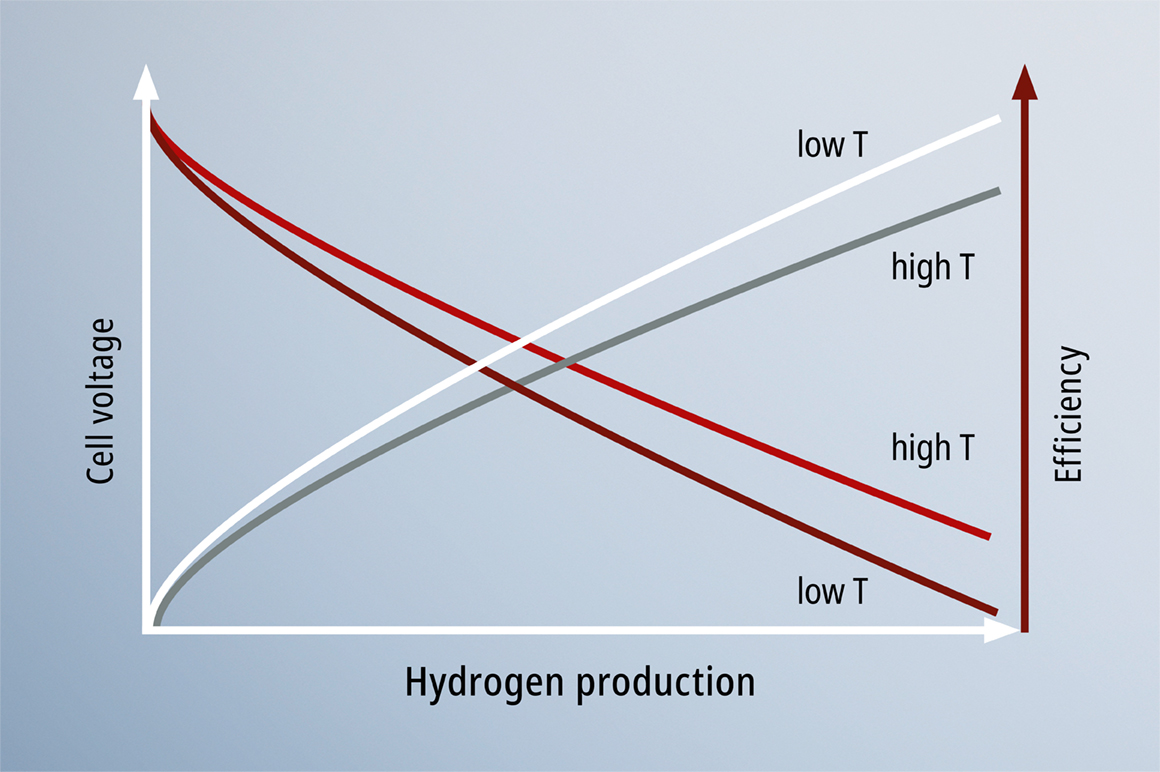

Temperature measurement

Another important factor during the electrolysis process is the temperature of the cells; the higher the temperature is, the higher the efficiency, but the shorter the service life will be. It therefore makes sense to monitor the temperature of the electrolyzer at several points in order to ensure that heat distribution is as uniform as possible. Here, too, Beckhoff offers a comprehensive portfolio of measuring devices in IP20 design for the control cabinet or IP67 for direct mounting on the system.

Components such as RTDs, NTCs, or thermocouples can be connected. To acquire these signals, a suitable product from the Beckhoff portfolio can be chosen that meets accuracy and sampling rate requirements.

Numerous other parameters also have an influence on the production of green hydrogen using electrolysis. These parameters must be closely monitored in order to optimize the service life and efficiency of electrolysis. Many of these measurements are determined by field devices and connected to a standard analog input with 4...20 mA.

Energy monitoring

The energy measurement products from Beckhoff offer considerable advantages with respect to the monitoring and control of hydrogen electrolyzers. Using EL34xx EtherCAT Terminals and SCT series current transformers to perform precise current and voltage measurement of the power flowing into the electrolyzer enables operators to effectively detect and respond to load peaks and anomalies, such as increasing consumption over time. The EL34xx distributed power measurement terminal from Beckhoff demonstrates its cost efficiency particularly in voltage distribution boards with a large number of loads to be measured: up to six current channels can be measured in just 12 mm of installation space. The corresponding voltage values are recorded once in the system and transmitted to the current measuring devices via EtherCAT, ensuring efficient and precise distribution of the measured values.

In addition to energy measurement, the monitoring of material flows also plays a decisive role. The material flows (water flowing into the electrolyzer and hydrogen and oxygen flowing out) must be continuously monitored in order to optimize the operation of the electrolyzer. Beckhoff collects the measurement data from the corresponding sensors easily via EtherCAT and many other supported bus systems. This sensor data can then be accounted for using PC-based control from Beckhoff, enabling operators to quickly identify and correct plant malfunctions or inefficient operation.

In combination with Beckhoff IoT solutions, transparent, flexible, and cost-effective energy management becomes possible. The data can be monitored and analyzed in real time, resulting in improved operational management and optimized energy efficiency. This comprehensive monitoring and analysis helps to extend the service life of the electrolyzers and reduce operating costs, which ultimately improves the economic efficiency and sustainability of hydrogen production.

Condition monitoring of the gas installation

Plants for hydrogen production, transportation, and consumption are equipped with extensive gas systems such as pipes, pumps, and valves. The integrity of the pipelines and pumps that transport hydrogen is crucial to avoid leaks and potential hazards. By continuously monitoring mechanical parameters such as pressure, temperature, and vibrations, signs of wear or material fatigue can be detected at an early stage. Condition monitoring of the pipe systems for mechanical analysis of the components is important to ensure long-term operational safety. Beckhoff offers various solutions to implement this mechanical monitoring.

Pumps used in hydrogen plants are exposed to high mechanical loads. It therefore makes sense to equip them with vibration sensors that are read into the central plant monitoring system via Beckhoff EtherCAT analog I/Os (as IEPE or 10 V/20 mA signal, available in IP20 and IP67 design). This makes it possible to detect mechanical anomalies at an early stage. Beckhoff provides powerful PC-based control platforms and specific PLC libraries or the TwinCAT Analytics data handling platform for calculation. They mathematically extract and visualize the useful characteristic values from the measured values. In addition to mechanical monitoring, it is also a good idea to record the up-to-date current values of the pumps. EL34xx EtherCAT Terminals with up to 100 ksamples/s per phase are an ideal option for measuring these values. In addition, temperature may be recorded via discrete sensors and read in via RTD/TwinCAT analog inputs in the Beckhoff I/O systems.

These three types of measurement are an excellent way of monitoring the state of installation components. Condition monitoring helps to identify irregularities in operation that may indicate storage problems or imbalances. These analyses make it possible to carry out targeted maintenance measures before a failure occurs.

Targeted monitoring can also be useful on valves with regard to temperature development due to expansion processes or with regard to the actual valve position. Such signals are easy to read in with the Beckhoff I/O systems. Finally, vibrations in the pipelines themselves are a critical factor. Where necessary, these can also be reliably measured using the methods mentioned.

Overall, PC-based condition monitoring contributes to the safety and efficiency of hydrogen plants by detecting and addressing mechanical problems at an early stage. This minimizes the risk of failures and accidents, extends the service life of the plant components, and ensures safe operation.