TwinCAT HMI enables an efficient engineering of user interfaces directly in the Visual Studio environment. The resulting HMI can be executed responsively on any HTML5-capable browser, irrespective of operating system, resolution or display.

More about this video

Automatisation

TwinCAT offre de nombreuses fonctionnalités et une large gamme de blocs de fonction logiciels pour toutes les tâches d'automatisation.

TE2000 | TwinCAT 3 HMI Engineering

The TwinCAT 3 HMI (human-machine interface) integrates itself into the well-known Visual Studio® development environment. Based on the latest web technologies (HTML5, JavaScript), it allows the user to develop platform-independent user interfaces that are responsive, i.e. they automatically adapt to the screen resolution, size and orientation at hand. With the graphical WYSIWYG (what-you-see-is-what-you-get) editor, controls can be easily arranged via drag-and-drop and linked with real-time variables.

TF2000 | TwinCAT 3 HMI Server

The TwinCAT 3 HMI Server is a modular web server that provides the human-machine interface (HMI). It supports all CPU classes from Arm® to multi-core. The powerful architecture enables a wide range of application scenarios from local panel solutions to multi-client, multi-server and multi-runtime concepts.

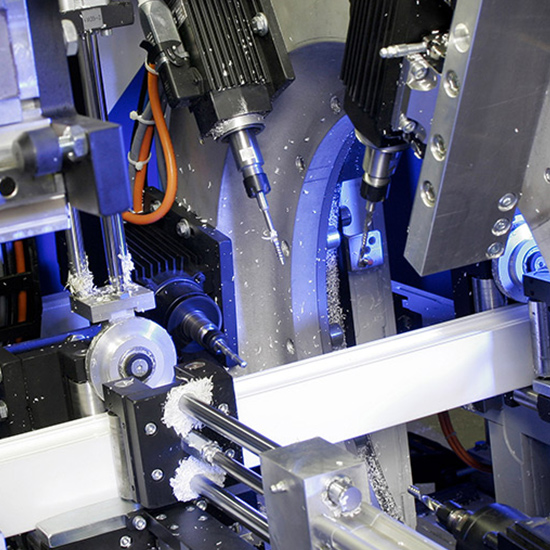

Woodworking machines

PC-based control from Beckhoff provides a competitive edge in the woodworking industry by optimizing transport and handling along with edge, CNC and surface processing.

Window production machines

PC-based control solutions from Beckhoff increase the efficiency and performance of window production machines and also simplify engineering.

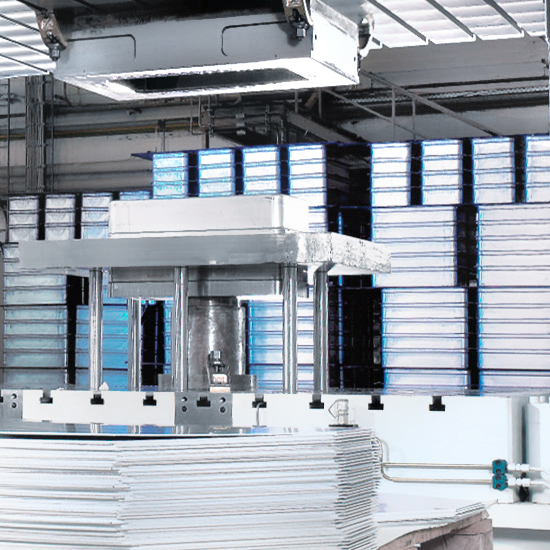

Sheet metal working

High performance built-in: PC-based control from Beckhoff for all control and drive applications in sheet metal working

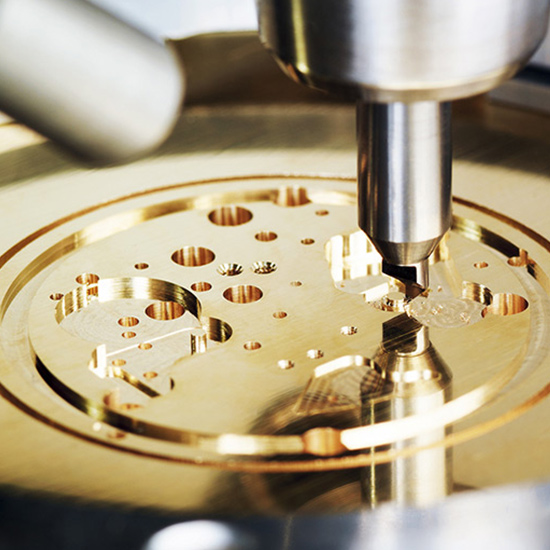

Machine tools

Scalability and high performance: The integrated software CNC solution from Beckhoff increases the productivity of machine tools.

Packaging machines

PC-based control significantly increases the productivity and flexibility of packaging machines and lowers the consumption of resources.

Tire and rubber industry

Leading the way in the rubber and tire industry: PC-based control technology from Beckhoff optimizes the production process.

Process industry

PC-based control: The universal solution for automation and process technology

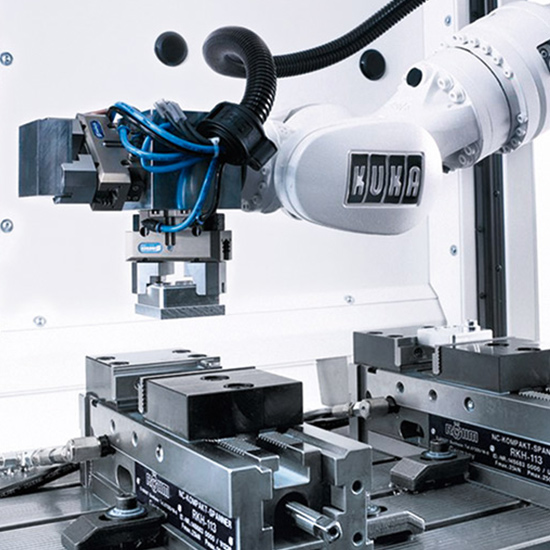

Handling and assembly technology

PC-based control technology from Beckhoff optimizes the entire process chain: from handling, production, and assembly to testing, control, and management.

Marine industry

PC-based control solutions from Beckhoff enable automation in a multitude of shipbuilding applications.