Many metalworking shops still hand-finish stainless steel, regular steel and aluminum parts. Automated machines such as the modular finishing gantry made by Peitzmeier deliver significantly higher quality and make production processes more efficient while easing the workload of employees. To achieve its full potential, however, such a system must be able to handle the widest possible range of parts. The PC-based control technology from Beckhoff makes this flexibility possible.

More about this video

CX2020 | Basic CPU module (service phase)

The CX2020 has a 1.4 GHz Intel® Celeron® CPU, it is fanless and has no rotating components. In addition to the CPU and chipset, the CX2020 also contains the main memory with 2 GB RAM as standard. 4 GB is possible as an option. The controller boots from the CFast flash memory card.

CP39xx | Multi-touch Control Panel

Balance between latest PC technology and long-term availability of control components Modern Control Panel technology doesn't stop with the selection of the touch technology, which forms the basis of the operation of a machine or plant. The transmission of the image and touch signals, combined with the power supply or other digital signals, must work perfectly and continuously, both mechanically and electrically, and over long distances in the industrial environment. In order to reliably ensure this, Beckhoff installs Panel electronics that it develops and manufactures itself at the production location in Verl.

TwinCAT

The TwinCAT software system turns almost any PC-based system into a real-time control with multiple PLC, NC, CNC and/or robotics runtime systems.

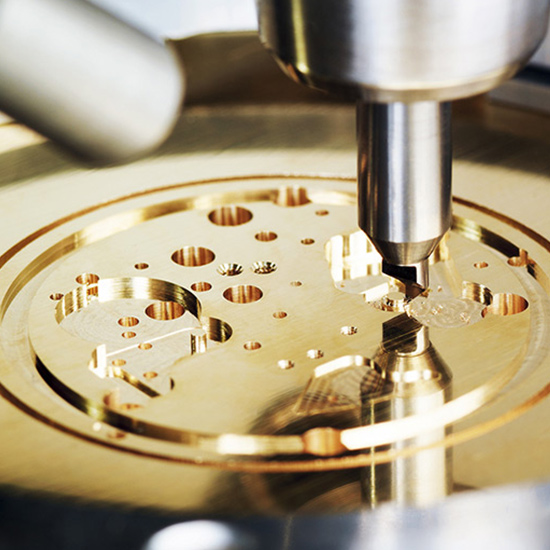

Machine tools

Scalability and high performance: The integrated software CNC solution from Beckhoff increases the productivity of machine tools.