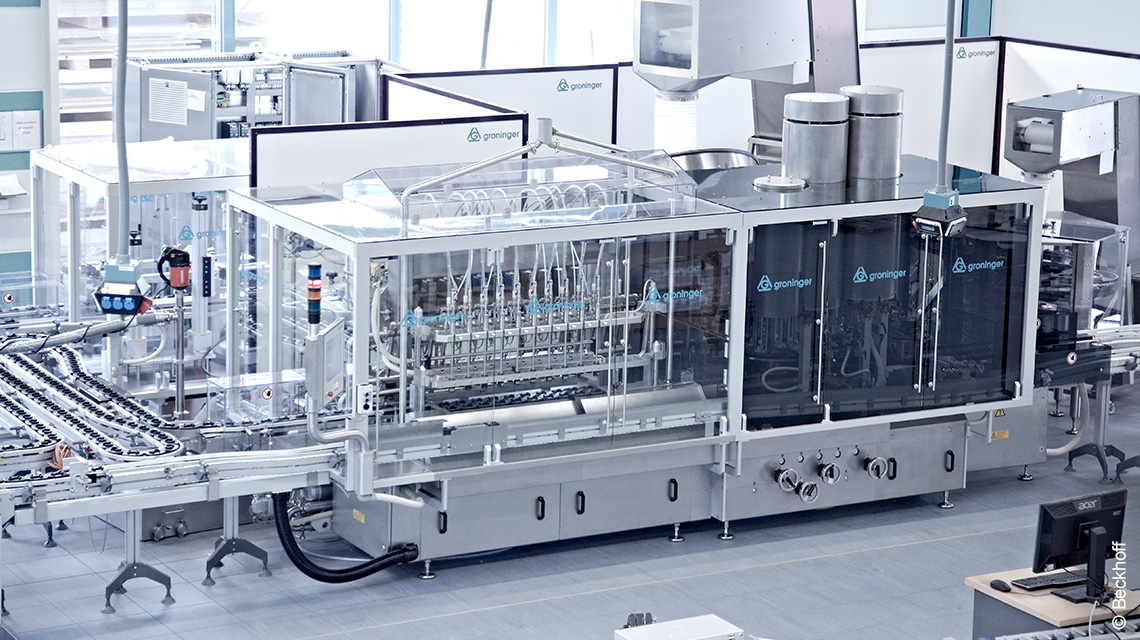

Linear transport system deployed in cosmetics filling line

For 35 years, Groninger & Co. GmbH has been developing technologically advanced machinery and equipment for the pharmaceutical industry at its headquarters in Crailsheim, Germany, and for the cosmetics industry at its nearby facility at Schnelldorf. Hubertus Ritzenhofen, Sales Director Cosmetics, explains: “One of our key success factors is in-depth industry and technology expertise. Every year, Groninger invests 10 % of its revenues in research and development. This is also true for our cosmetics division, which includes filling systems for all liquid cosmetics, ranging from aqueous products such as mouthwash to highly viscous creams and paste-like materials such as mascara.”

Markus Regner, Technical Director at Groninger, provides a recent example: “Key demands for the fragrance filling system for a large Brazilian cosmetics manufacturer were speed and flexibility, with minimum footprint. The plant is capable of filling 150 bottles of eau de toilette or fragrance per minute, which equates to 300,000 bottles per day in three shifts. The system must be able to handle bottles with a very complex seal pattern. An additional factor is that the line currently processes eight different products and has to offer adequate flexibility for future product changeovers.” Hubertus Ritzenhofen concurs: “The biggest challenge in the cosmetics sector is the large variety of formats. In some cases, one machine handles up to a hundred different container formats. Flexibility in terms of the end products is therefore crucial.”

Innovation potential fully utilized in space-saving bottle handling unit

Flexibility was also a key requirement during the development process of the fragrance filling system, as Hubertus Ritzenhofen explains: “On the one hand, we had to take into account increased customer requirements in terms of system output, on the other hand less space was available for the machine than originally planned. In view of these basic requirements, it was not possible to implement our preferred concept of a linear machine layout, i.e. a monoblock system consisting of a clocked filling machine and a continuous sealing machine, in a conventional manner. The high output speed would have required extensive accumulating conveyors between the system components, and for that no space was available.”

“XTS from Beckhoff enabled us to implement a highly compact bottle handling unit between the system components”, says Markus Regner. “By eliminating the accumulating conveyors we were able to reduce the system length from 7.5 m, as originally envisaged, to approximately 6 m. It is worth noting that such a significant reduction was not in itself decisive, because even an excess length of only 10 cm would make a conventional linear machine design impossible to implement. This would result in disadvantages for implementing the filling process, which not only requires time, but also plenty of expertise, and can be controlled much better in a linear process.” Hubertus Ritzenhofen adds: “We, and indeed our customers, are convinced of the benefits of a linear process, both from an application and operation perspective, as well as in terms of maintenance. By means of the XTS we were able to realise a linear machine and still meet the output requirements of the Brazilian cosmetics manufacturer, which conventionally would only have been possible with a circular filling line.”

Software functionality not only reduces the hardware requirements

XTS can replace conventional hardware through software functionality. Markus Regner: “With the XTS, we were able to do without with space-consuming accumulating conveyors, not to mention the fact that the eXtended Transport System is itself very compact. A further benefit is that it can be used in any installation position. In this filling system, it is tilted by 45° relative to the conveying direction. The workpiece carrier grippers are also tilted by 45°, so that the required handling unit can be realized with minimum space requirement, using horizontal grippers for the product transport in forward direction and vertical grippers for maximum space-saving on the way back.”

Markus Regner sees further significant benefits, such as the enhanced flexibility and quality of the product handling: “In this plant, batches of 10 bottles exit the filling area. In a conventional system, this batch would enter a balancing loop, resulting in abrupt deceleration. Depending on the speed, this may lead to spilling of liquid. This situation could, of course, be handled adequately, but it would mean that a fully controllable product – i.e. the filled bottle – would have to be removed from the controlled process and only returned to it afterwards during sealing. With XTS, the products can be controlled throughout, and bottle accumulation can be optimized, based on software functionality. Therefore, XTS makes it possible to process complicated or difficult product container batches more quickly with the same machine.”

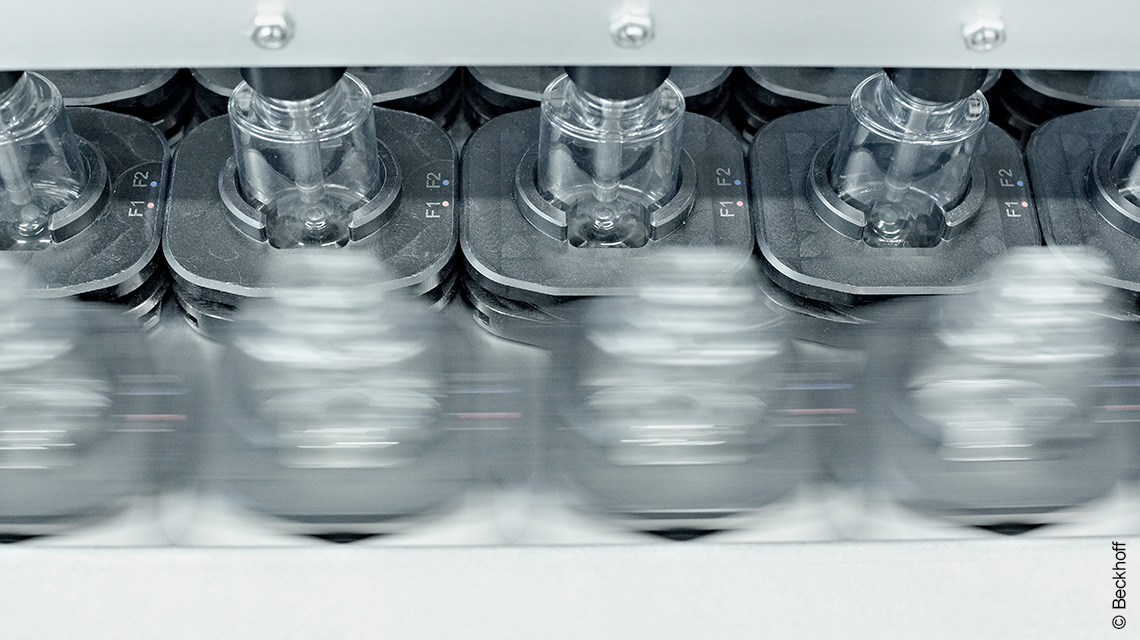

30 movers on an oval track

The XTS system for the cosmetics filling line consists of a total of 20 straight motor modules, each 25 cm long, and semicircles used as curve modules, as well as 30 movers with semicircular grippers for the workpiece carriers. The result is an oval track with a length of approximately 3 m. The whole system – with a path velocity of 1.5 m/s and a maximum mover acceleration of 10 m/s² – is controlled by a single C6920 control cabinet PC with a control cycle time of 2 ms.

Batches of ten bottles are filled at standstill, in order to be able to meet the demanding process requirements. The fragrance containers are then sealed in a rotary process, that is, a continuous process. Markus Regner points out: “A block of 10 elements has to be synchronized with the continuous sealing machine from standstill, within a relatively short time and a short distance of less than 1 meter. This is a rather demanding task, which can be optimally solved with XTS. A further aspect is that during the filling process, the ten grippers waiting for full bottles are positioned directly side by side, without a gap in between. However, when entering the sealing machine, they must have a certain, equidistant spacing. Incidentally, this also applies to the distance of two groups of ten, between which no gap should occur. All these are ideal applications for XTS.”

Exploiting additional efficiency potential

The XTS system at Groninger currently uses 30 movers: a group of 10 bottles in the filling area, a further group at the synchronisation stage in the sealing machine, and a third group during discharge from the sealing processes or on the way back to the filling area. Markus Regner already sees future efficiency potential: “We could optimize further and utilize the capacity reserves of XTS even better, in order to save a few more movers and therefore costs.” And he adds: ”Moreover, XTS enables process sequences to be mapped in such a way that we could duplicate the slowest sub-process, resulting in a significant further increase in overall processing speed. Typical examples are complicated and therefore time-consuming sealing mechanisms or additional processing steps that emerge during the machine development as a result of retrospective product modifications.”

Further information

More about this video

XTS | Linear product transport

As an intelligent transport system, the eXtended Transport System enables flexible motion profiles and new types of machine concept.

Packaging machines

PC-based control increases the productivity and flexibility of packaging machinery.