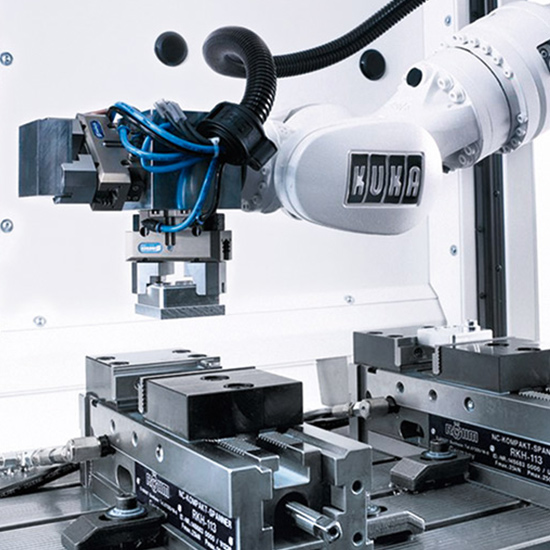

Machine vision integrated into automation technology.

More about this video

TwinCAT Vision seamlessly integrates machine vision into automation technology

With TwinCAT Vision, Beckhoff has incorporated comprehensive image processing capabilities into its PC-based control system. TwinCAT software unites a comprehensive range of machine functionality – PLC, motion control, robotics, high-end measurement technology, IoT, HMI and now machine vision – all in an end-to-end engineering and control platform. With this level of integration, TwinCAT Vision eliminates the need for separate vision solutions, often developed by third parties. The software opens up vast innovation potential in machine building – for instance, through consistent real-time synchronisation with other automation tasks or support of advanced track-and-trace solutions.

TwinCAT

The TwinCAT software system turns almost any PC-based system into a real-time control with multiple PLC, NC, CNC and/or robotics runtime systems.

Packaging machines

PC-based control significantly increases the productivity and flexibility of packaging machines and lowers the consumption of resources.

Assembly and handling technology

PC-based control technology from Beckhoff optimizes the entire process chain: from handling, production, and assembly to testing, control, and management.

Woodworking machines

PC-based control from Beckhoff provides a competitive edge in the woodworking industry by optimizing transport and handling along with edge, CNC and surface processing.