TwinCAT 3 Redundancy

The software solutions for increased plant availability

Headquarters Canada

Beckhoff Automation Ltd.

The software solutions for increased plant availability

Redundancy is particularly important in sensitive control and communication processes. By building redundancy into the automation technology, plant availability can be increased. This is because if a component fails, its tasks are taken over by the redundant component to allow production to continue seamlessly. When this takes place, it is not only essential for the components to switch reliably, but also for the corresponding diagnostic options to be available at the same time, as this is the only way to allow the failed component to be repaired.

TwinCAT 3 offers redundancy solutions for different application areas to safeguard control and communication processes, which can be used to increase plant availability.

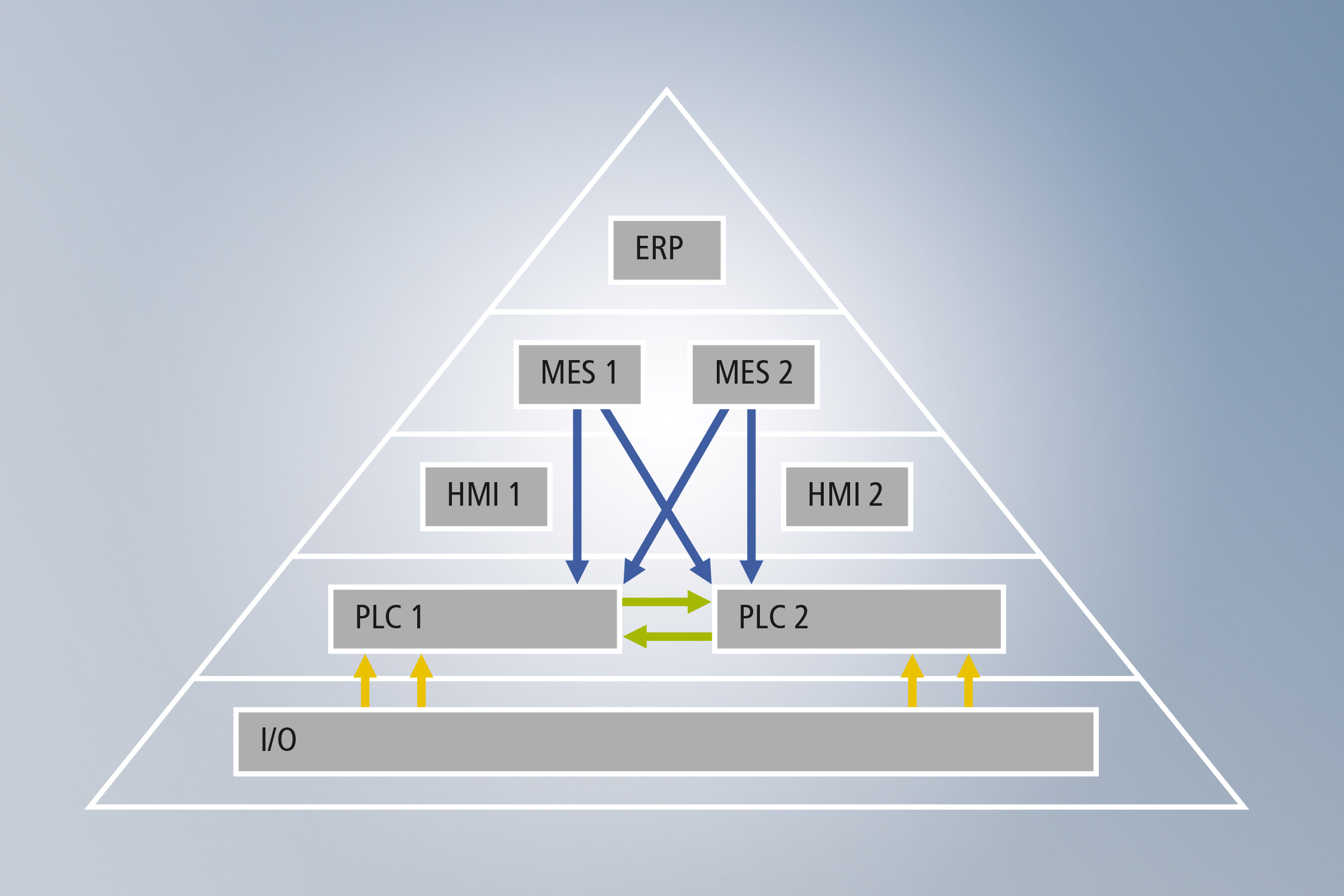

TwinCAT 3 Redundancy offers the possibility of increasing availability with three different products for a wide range of different tasks. These three products are schematically arranged in the automation pyramid on the right.

TwinCAT 3 EtherCAT Redundancy offers a redundant connection to the fieldbus level in order to facilitate communication with the I/O level. The TwinCAT 3 Parallel Redundancy Protocol (PRP) can be used at MES (Manufacturing Execution System) level, as well as for horizontal communication between different systems. TwinCAT 3 Controller Redundancy is a new feature that increases the availability of the PLC itself.

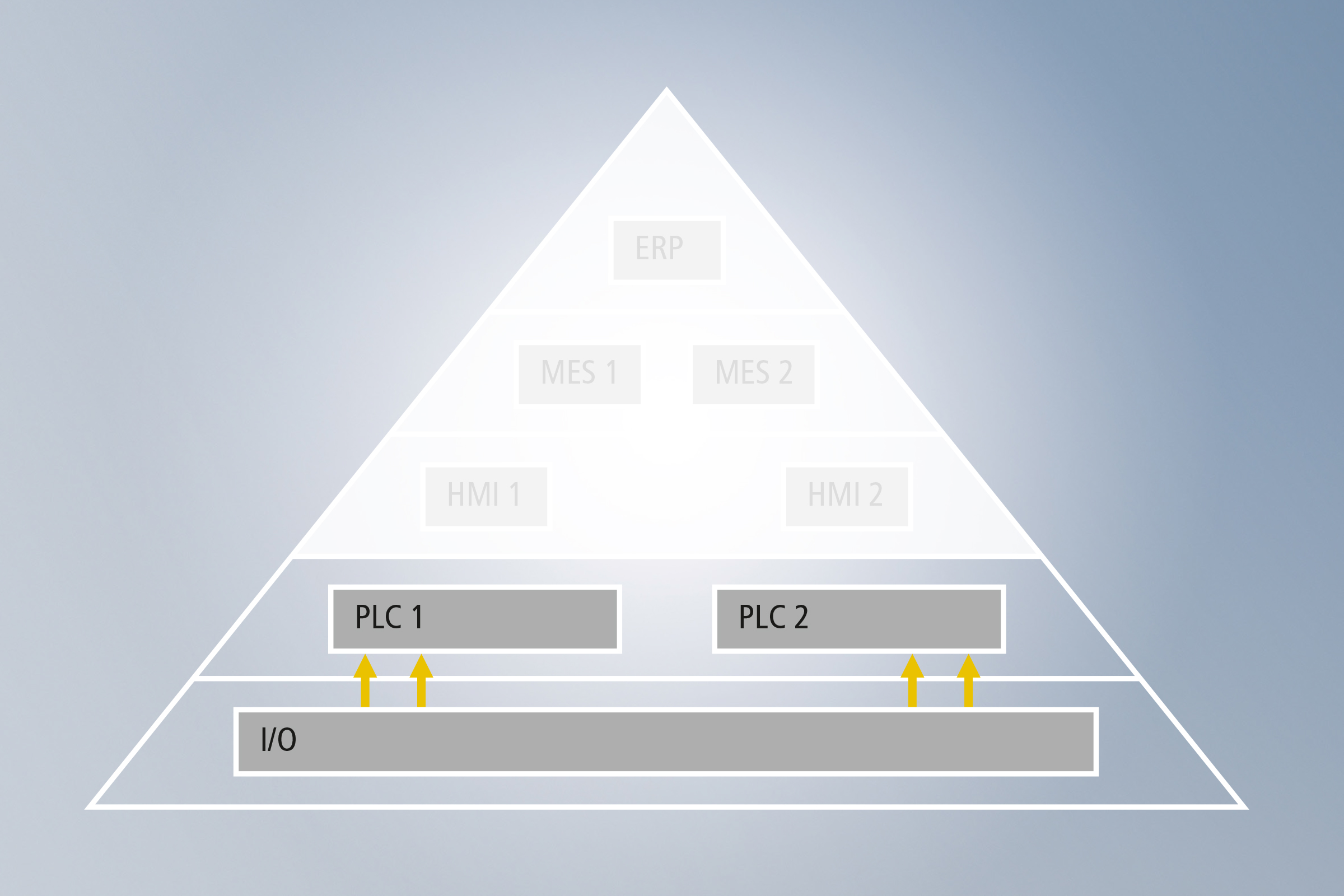

TF6220 TwinCAT 3 EtherCAT Redundancy offers the possibility of implementing cable redundancy. To this end, an additional cable connection is established from the last EtherCAT slave to the master. In the event of a cable breakage, telegrams can be sent seamlessly via the alternative connection.

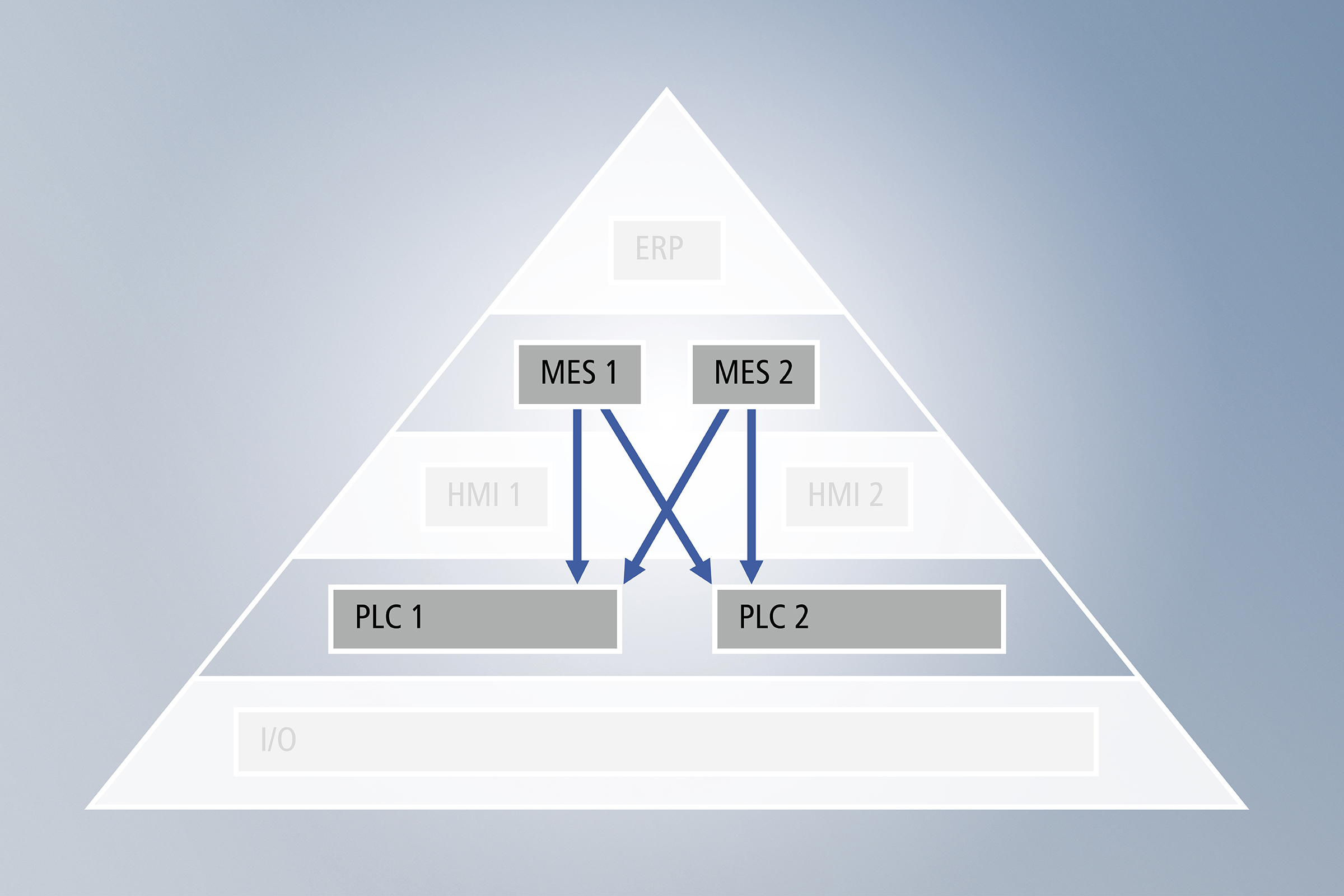

The TF6230 TwinCAT 3 Parallel Redundancy Protocol provides a network connection according to IEC 62439-3 that can be used transparently by different applications – both from real time as well as from operating system applications. The interface is designed with redundancy on the network side in the interests of higher overall availability.

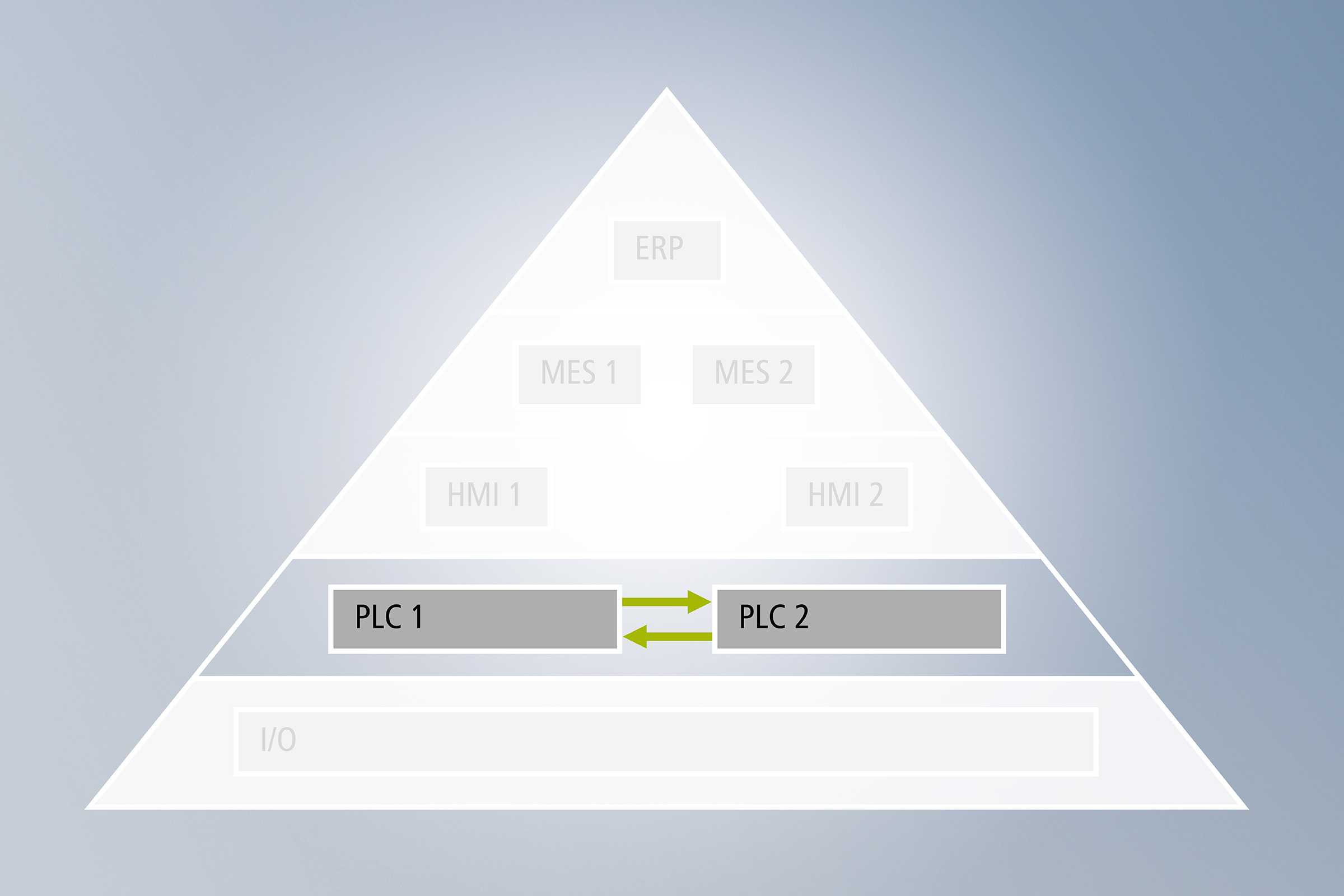

TF1100 TwinCAT 3 Controller Redundancy provides an extension to enable redundant processing of TwinCAT 3 PLC programs on two industrial PCs and increases availability in the process.

Product Manager Dr. Henning Mersch explains in this video the structure and functionality of a controller redundancy: TwinCAT 3 Controller Redundancy with standard hardware components (Video)

TwinCAT 3 Controller Redundancy provides an extension to enable redundant processing of TwinCAT 3 PLC programs on two industrial PCs and increases availability in the process.

The EtherCAT technology enables the realization of cable redundancy. For this purpose, an additional cable connection is established from the last EtherCAT slave to the master. In the event of a cable breakage, the telegrams are sent seamlessly via the alternative connection.

The TwinCAT 3 Parallel Redundancy Protocol provides a network connection according to IEC 62439-3 that can be used transparently by applications. This can be used both from real time and from operating system applications. The interface is designed with redundancy on the network side in the interests of higher availability overall.