TwinCAT 3 Lighting Solution: The lighting solution for DALI-2

With the TwinCAT 3 Lighting Solution, Beckhoff has introduced an Excel-configurable lighting solution that focuses on simplifying all work steps from engineering to maintenance. All conventional lighting controllers are integrated and the number of DALI lines is unlimited. The TF8050 TwinCAT 3 Lighting Solution is fully web/HTML5-capable, decentrally scalable, and can be operated directly via a panel. Quick function changes, addressing, and extensions can be performed immediately during operation, as can DALI line-independent groupings of DALI devices. Even daylight-dependent human-centric lighting concepts can be implemented with the TF8050.

Advantages of the TwinCAT 3 Lighting Solution at a glance:

- supports DALI-2 devices and option to integrate Beckhoff I/O terminals (relay terminal, 0…10 V analog output terminal, etc.)

- high level of planning flexibility: unlimited number of DALI lines, groups spanning DALI lines, supports 200 lighting groups and 30 scenes, decentralized I/O stations

- straightforward configuration via HMI – no programming required

- includes all common lighting functions such as human-centric lighting, constant light regulation, daylight control, and staircase function

- DALI device monitoring and operating hours count of control gears for maintenance purposes

- HTML 5 based visualization interface on panels, tablets, and mobile devices

- Excel tables for configuration of and saving settings

- option to extend the program with own PLC and HMI code

- option to connect to BMS systems and the cloud – for example, via BACnet/IP, OPC UA, Modbus/TCP, or MQTT

Rapid configuration with comprehensive functions: Lighting management with the TwinCAT 3 Lighting Solution

The TF8050 TwinCAT 3 Lighting Solution is a purely configurable software solution for lighting management from Beckhoff. The required hardware is linked to the TF8050. After activating the controller, all necessary settings for lighting control and DALI addressing are executed via the integrated and intuitive visualization interface.

Simple installation

The TF8050 TwinCAT 3 Lighting Solution can be installed on all Beckhoff Embedded, Panel, or Industrial PCs. The software solution uses the DALI-2 certified KL6821 DALI master terminal as the core hardware component, although other terminals can also be used to connect lights and sensors. The number of DALI-2 lines per controller is essentially unlimited. To facilitate the wiring process, decentralized I/O stations can be set up using the BK1150 EtherCAT Bus Coupler or the BK9050 Ethernet Bus Coupler, for example. The TF8050 is also able to meet the relevant requirements for all project specifications.

Easy configuration

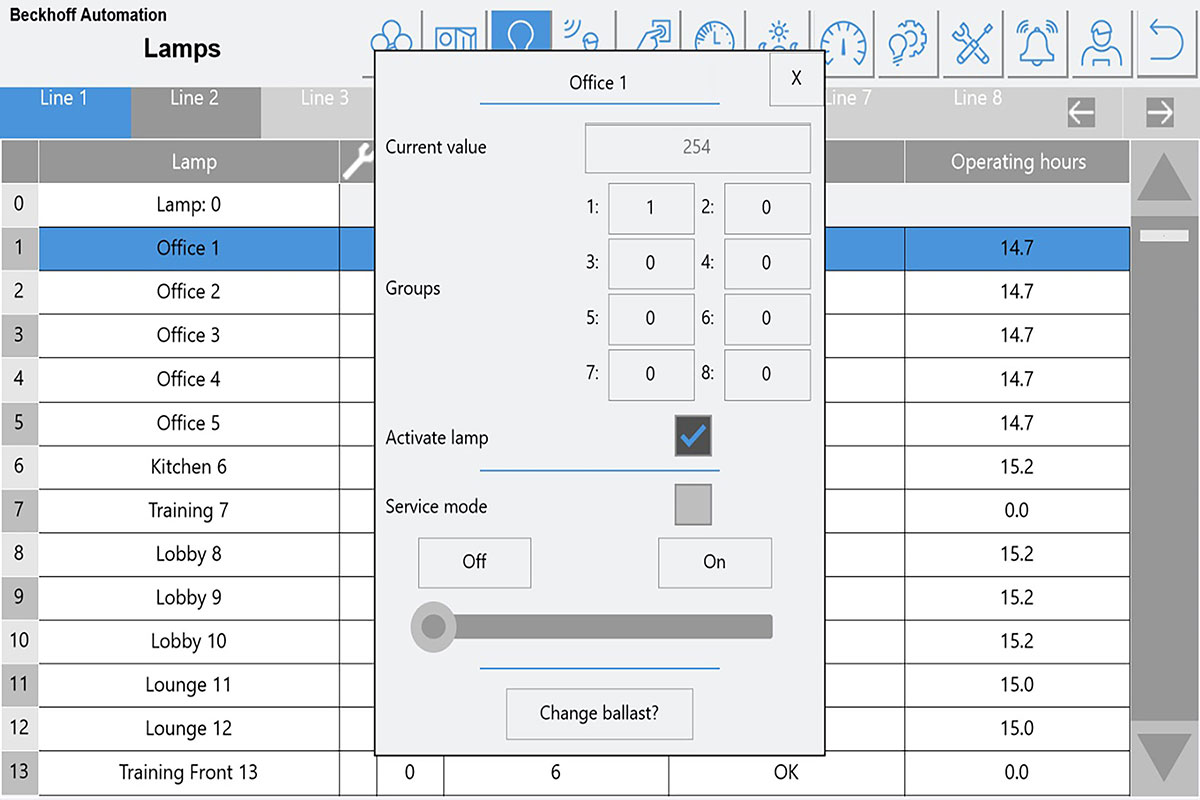

The TF8050 is a TwinCAT 3 software library that can be operated on all Beckhoff controls. In terms of commissioning, only the project-specific I/Os have to be connected to the TF8050 project, and all necessary light settings and DALI device addressing processes are subsequently performed via the integrated visualization interface. As device addressing is integrated into the TF8050, no additional DALI tools or expertise in how to handle these tools is required. What’s more, it is also easy to readdress and extend DALI lines at any time during runtime.

When it comes to configuring the lighting settings, the integrated visualization interface provides an excellent tool for rapid commissioning. All main lighting control functions can be selected individually for each lighting group. The TF8050 supports functions such as human-centric lighting (HCL), daylight control, and constant light regulation, as well as schedulers and timers for implementing individual controls. Another major advantage of the TF8050 is that it allows devices from one lighting group to be assigned to different DALI-2 lines, meaning that groupings can span DALI-2 lines and controls can be flexibly implemented.

Easy to adapt

All lighting control settings can be changed and adjusted during runtime via the integrated visualization interface. What’s more, DALI-2 input devices can be freely configured to control any of the 200 available groups. The DALI-2 control gears can also be assigned to several of these groups, making the TF8050 one of the most flexible lighting solutions on the market. The intuitive visualization interface allows lighting controls and groups to be adjusted with ease.

As if this integrated solution didn't simplify commissioning enough, it also offers further options to make commissioning faster and more convenient than ever, since the TF8050 also supports Excel sheets for configuration. The preconfigured light settings can be saved in Excel files and then used on site – for example, by transferring them to the controller via FTP or USB. This means that as soon as the DALI devices are addressed, further configuration can be activated by loading the configuration Excel sheets. If subsequent changes are made, the new settings can be saved on the controller and copied to a USB stick as a backup.

Simple operation

When it comes to controlling and monitoring the lighting, the visualization interface integrated into the TF8050 offers a clear and fully comprehensive solution. Buttons for easy access are available on the home page for the main lighting groups, and there are also visualization pages for calling up and configuring scenes for different lighting environments. This allows users to modify and change scene settings with ease. All 50 timetables and calendar functions used to control lighting can be configured as required.

The functionality of DALI devices is constantly monitored, so if there are problems in the DALI line or in the DALI devices, an alarm is displayed with a clear description of the cause of the problem. External alarms can also be configured and visualized with individual texts. The TwinCAT 3 Lighting Solution also supports energy data monitoring with the Beckhoff KL3403 power measurement terminal. All relevant data can be recorded – including current and power for all three phases as well as the sum of these measurements. Energy data is recorded every 15 minutes and stored in a separate CSV file on the controller. The CSV file can be opened in Excel, for example, for further analysis of the electrical data.

The TwinCAT 3 Lighting Solution in action

Beckhoff production hall for I/O components

In our production hall for I/O components, all lighting control is performed by the TF8050 Lighting Solution. The TF8050 runs on a CX5020 and controls 874 lights and 88 DALI motion sensors, which are connected via corresponding DALI-2 bus terminals. Installation and commissioning can be implemented quickly and easily thanks to the high compatibility of software and hardware.

The TF8050 provides optimal lighting conditions in the production hall, and different lighting environments can be set at the touch of a button. The TF8050 Lighting Solution also adjusts the color temperature (HCL) in production. The integrated daylight control system enables high energy savings during operation, with the lighting being automatically adjusted for optimum efficiency depending on the position of the sun and the natural incidence of light. In addition to lighting control, a whole host of further functions are also integrated into the control via TwinCAT, such as the control of ventilation, air-conditioning equipment, roof domes, and radiator valves. This enables maximum exploitation of all energy-saving opportunities.

The Omniturm in Frankfurt am Main

The Omniturm in Frankfurt is a literally outstanding project in which the TF8050 TwinCAT 3 Lighting Solution from Beckhoff forms the lighting control system.

Across more than 40 floors, the lighting solution controls some 10,000 LEDs with HCL and collects data from 2,500 sensors with maximum flexibility, since the lighting behavior on each floor can be individually adjusted via the building management system.

However, the automation possibilities go far beyond simply switching the lights on and off: further options include dimming, presence-dependent switching on and off, daylight-dependent control, and the additional activation of human-centric lighting (HCL). While presence-dependent switching and daylight-dependent control, for example, have great energy-saving potential, human-centric lighting focuses on people. As such, the effect of light – and therefore the lighting settings – are geared to people’s emotional, visual, and biological requirements with the aim of improving the quality of their work and lives.

The sheer size of the building and the various setting options for each floor meant the implementation of this technically demanding lighting control was no mean feat, but the TF8050 TwinCAT 3 Lighting Solution was able to bring this project to fruition reliably and comprehensively with outstanding results.

Products

TF8050 | TwinCAT 3 Lighting Solution

The Beckhoff Lighting Solution offers many advantages, among them the simple commissioning of DALI lighting controllers. With extensive lighting systems, the use of decentralized bus couplers installed in the network infrastructure considerably reduces cabling requirements. The TwinCAT 3 Lighting Solution supports functions such as remote control via web, the import and export of Excel data or simple maintenance measures. The solution also includes functions for the Human Centric Lighting (HCL) concept and the integration of DALI-2 sensors. All these functions are easy to configure without specific programming skills.

KL6821 | Bus Terminal, 1-channel communication interface, DALI/DALI-2, master/power supply

The KL6821 enables the connection of up to 64 DALI/DALI-2 slaves and 64 DALI-2 input devices. The KS2000 software enables simple configuration via a PC that is directly coupled with the bus coupler via an RS232 interface or via the fieldbus. Operation is done exclusively via TwinCAT function blocks. The KL6821 contains an integrated, switchable DALI bus power supply with galvanically isolated output voltage. No further components are required for the operation of the DALI/DALI-2 devices.

CP6600, CP6606 | Economy built-in Panel PC

The CP6600 and CP6606 built-in Panel PCs are designed for installation in the front of a control cabinet or control housing and can be used for a variety of applications in machine construction and plant engineering – for example, as a stand-alone controller with the TwinCAT automation software running on Windows Embedded Compact 7 or as a remote desktop display. They are available with two different touch screen displays with a 7 or 10.1-inch screen size.

CP6700, CP6706 | Economy built-in Panel PC

The CP6700 and CP6706 built-in Panel PCs are designed for installation in the front of a control cabinet or control housing and, with their highly integrated 3½-inch motherboard, they represent a powerful platform for use in machine construction and plant engineering, for example with the TwinCAT automation software running on Windows 10 IoT Enterprise. They are available with two different touch screen displays with a 7 or 10.1-inch screen size.

CX9020 | Basic CPU module

The CX9020 is a compact, DIN rail-mountable Ethernet control system with 1 GHz Arm® Cortex®-A8 CPU. The connection for the Beckhoff I/O systems is directly integrated into the CPU module. The unit offers automatic bus system identification (E-bus or K-bus) and independently switches in the corresponding mode. The CX9020 comprises the CPU with two microSD card slots, the internal RAM and 128 kB NOVRAM as non-volatile memory. The basic configuration also includes two switched Ethernet RJ45 interfaces, four USB 2.0 interfaces and a DVI-D interface. The RJ45 interfaces are connected to an internal switch and offer a simple option for creating a line topology without the need for additional Ethernet switches. The operating system is Windows Embedded Compact 7. TwinCAT automation software transforms a CX9020 system into a powerful PLC and motion control system that can be operated with or without visualization. Optionally, the unit can be ordered with a fieldbus, serial or audio interface.

CX5120 | Embedded PC with Intel Atom® processor

The CX5120 has an Intel Atom® single-core processor with a clock rate of 1.46 GHz. The hardware interfaces in this series are oriented and implemented identically to those of the existing CX5000 series. Two independent, Gigabit-capable Ethernet interfaces as well as four USB 2.0 and a DVI-I interface are available. A multitude of further connection options or gateway functions are created by an optional interface, which can be pre-fitted in the factory, as well as the I/O level, which can selectively consist either of E-bus or K-bus terminals.

CX5140 | Embedded PC with Intel Atom® processor

The CX5140 has an Intel Atom® quad-core processor with a clock rate of 1.91 GHz. This makes genuine multi-core technology possible in the Embedded PC segment. The hardware interfaces in this series are oriented and implemented identically to those of the existing CX5000 series. Two independent, Gigabit-capable Ethernet interfaces as well as four USB 2.0 and a DVI-I interface are available. A multitude of further connection options and gateway functions is created by an optional interface, which can be pre-equipped ex factory, as well as the I/O level, which can optionally consist of either E-bus or K-bus terminals.