Economic success and innovative power

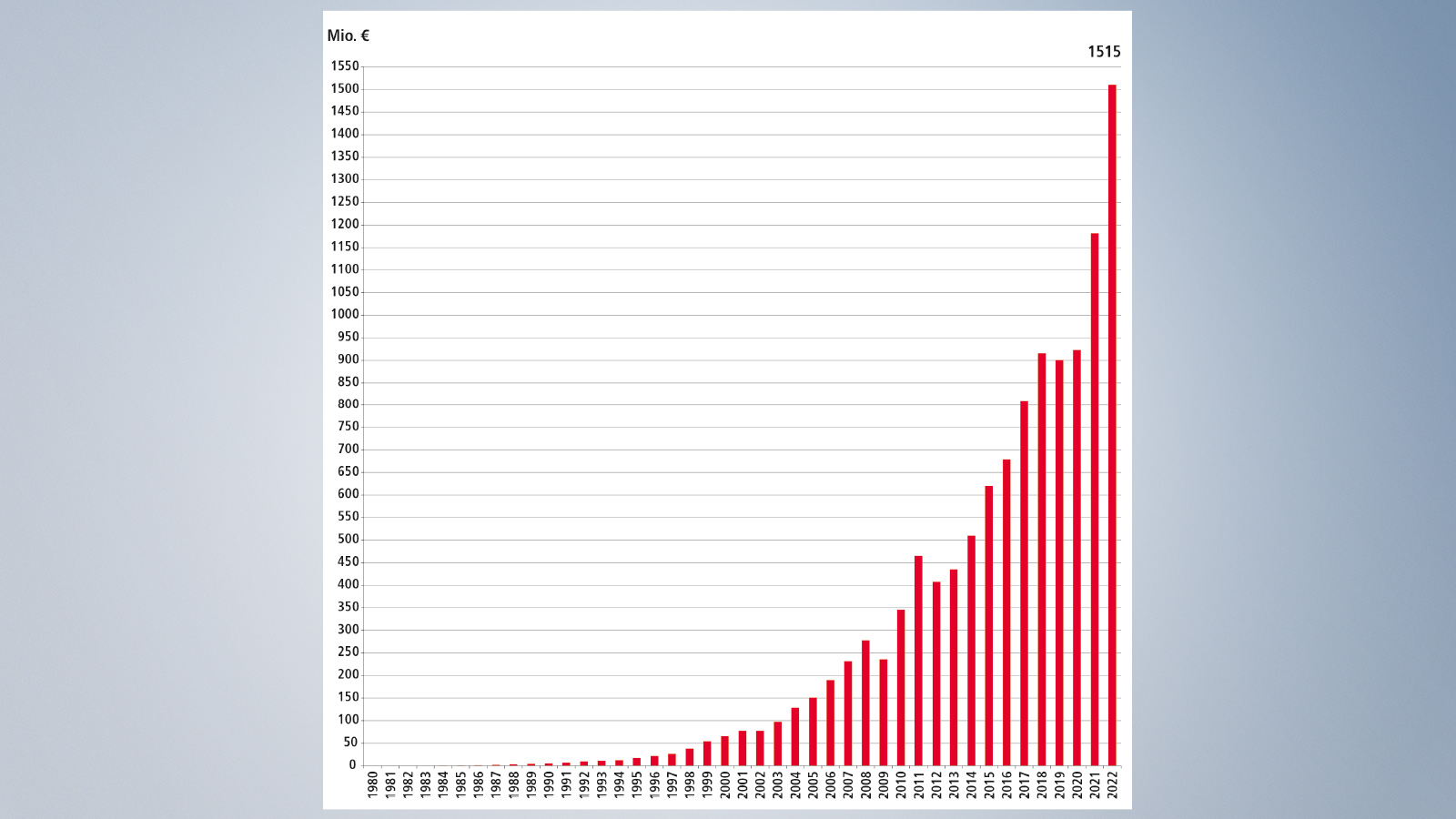

Beckhoff Automation successfully continued its growth trajectory in 2022, as this specialist for high-performance automation technology increasing its sales to 1.515 billion euros. This represents an increase of 28 percent in comparison with the previous year’s sales of 1.182 billion euros and has seen the company set a new record for its highest sales ever. Some 5,680 employees worldwide, including over 2,200 engineers, currently contribute to the company’s success.

“Some aspects of the past financial year were challenging due to global conditions. Nevertheless, we can look back on a successful year with great satisfaction, having achieved growth of 28% for the second year in a row,” enthuses Hans Beckhoff, founder and Managing Director of the family-owned company. He goes on to add, “Growth is something we have come to expect now. We have achieved average annual growth of 15% since 2000, but the 64% cumulative growth over the past two years, 2021 and 2022, has been exceptional, even for us!” However, rather than focusing on the past, the automation visionary has his sights set firmly on the future. Beckhoff will continue to grow sustainably, develop pioneering innovations, and bring new product lines onto the market in line with its New Automation Technology concept. To this end, the automation specialist will continue to consistently invest 80 million euros annually in its research and development activities.

Beckhoff also expects healthy double-digit growth for the current year, 2023, secured by a high number of orders in hand. However, a significant decline in order intake is currently being observed worldwide, largely attributable to the technical reaction to shortened delivery times, and which is only in small part due to the slight economic downturn.

The past two years have been characterized by tough supply bottlenecks in the semiconductor product sector, which forms an essential component of all Beckhoff products. This has led to extremely long delivery times for Beckhoff and the automation industry as a whole. Nevertheless, Hans Beckhoff believes that this situation is easing, “By the end of the year at the latest, perhaps even by quarter three, we will be in a position to generally confirm normal delivery times for our customers again.”

Countless technological milestones

Beckhoff has always been renowned for high-performance control and the way it continually pushes performance limits in the world of automation. “For 43 years, we have been a driving force behind innovative automation technology around the world. We are proud of our innovative spirit and the technology that has been born from it. This year, we are celebrating 20 years of EtherCAT,” Hans Beckhoff proclaims, highlighting one of the company’s most significant technology milestones. Indeed, this communication system, which was developed by Beckhoff and premiered at Hannover Messe 2003, has certainly established itself as a high-performance real-time Ethernet solution in a wide range of applications. It has consolidated its position on the market thanks to its continuity and technical development, even becoming an open IEC standard. EtherCAT has now become a world standard, a status that the protocol disclosure and the founding of the EtherCAT Technology Group (ETG) at SPS 2003 have made a huge contribution to. With over 7,000 member companies from 72 countries (as of March 2023), ETG is the world’s largest fieldbus user organization.

“2022 was a particularly big year of innovations for us,” reports Hans Beckhoff, summing up the past fiscal year. With the MX-System for control cabinet-free automation, a revolutionary approach has been presented that can replace the conventional control cabinet completely, thereby opening up entirely new methods of plant automation. This is complemented by a comprehensive hardware portfolio for machine vision, which expands the TwinCAT Vision software solution that was launched in 2017 into a complete system. As all components are EtherCAT-based, including the cameras, lenses, illumination, and complete units, they offer all the advantages of seamless integration into the control technology, such as highly accurate synchronization with all machine processes, reduced engineering and hardware costs, and simplified commissioning and support.

Another prime example is the ATRO (Automation Technology for Robotics) modular industrial robot system, which can be used to individually and flexibly assemble optimal robot structures for a wide variety of applications. A highlight of the system is the internal media feed for data, power, and fluids. This was implemented in such a way that all axes are designed to rotate endlessly, which enables better Cartesian accessibility as well as short positioning paths. ATRO’s innovative potential has also been recognized by the expert jury of the Hermes Award, which was announced during the Hannover Messe, with the system receiving a nomination for this year’s prestigious technology award.

From April 17 to 21, the Beckhoff exhibition booth at Hannover Messe has showcased not only these technological milestones, but also a whole host of innovations in line with the exhibition's central theme of ‘Digital Transformation of Production Processes’. One example is the implementation of innovative chatbot technology to increase productivity in control programming and optimize direct support: For this purpose, the TwinCAT Chat Client developed for the TwinCAT XAE engineering environment. This makes it possible to use Large Language Models (LLMs), such as ChatGPT from OpenAI, conveniently in the development of a TwinCAT 3 controller. In this way, for example, missing code from a function block can be completed automatically, or existing code can be optimized, documented, or restructured (refactored) for better readability.

Employees spark innovation

The company currently employs 5,680 people worldwide, with more than 2,200 holding engineering qualifications. “At Beckhoff, it is not uncommon for employees to remain loyal to the company, often for their entire careers. This is crucial and very important to us because they possess a great deal of knowledge and spark innovation – and this expertise, as well as their great enthusiasm, are what make us a technology leader in PC-based control technology,” explains Hans Beckhoff.

The company currently employs a total of just under 200 apprentices and students. To ensure the demand for highly qualified specialists can be met, Beckhoff trains young people for careers through many different apprenticeships. The company has also been focusing on work-integrated study programs since 2010. In cooperation with the Gütersloh campus of the Bielefeld University of Applied Sciences, five engineering degree programs are offered in the form of Mechatronics/Automation, Industrial Engineering, Product Service Engineering, Digital Logistics, and Digital Technologies. Every year, an average of 100 students from Beckhoff are trained there in engineering professions. “Our goal is to keep talented young people in the region,” says Hans Beckhoff, explaining the idea behind the work-integrated engineering courses. This cooperation model of work-integrated studies is also interesting for external parties – countries such as the USA, Mexico, Finland, Malaysia, and China are in discussions with the Bielefeld University of Applied Sciences to find out more about this study model and potentially implement it themselves or set up exchange programs.