PC-based control, the integrated control system for window production machines

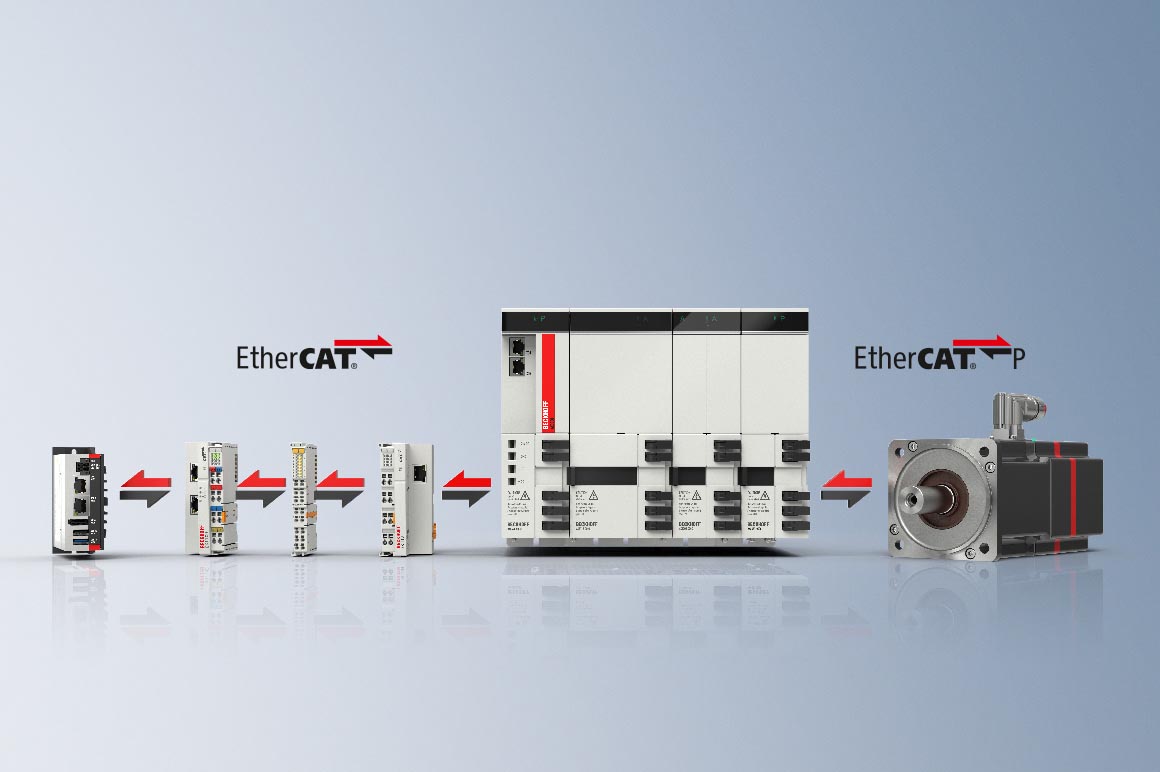

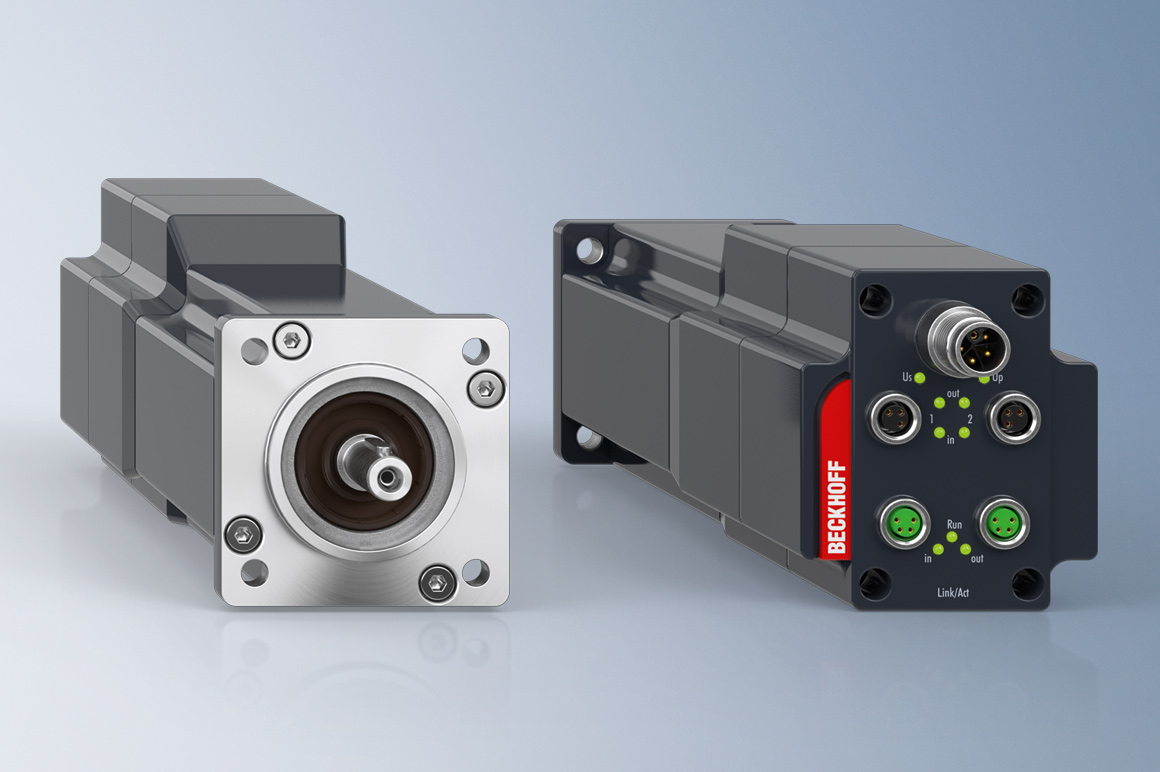

PC- and EtherCAT-based control systems from Beckhoff enable machine and system manufacturers to master the balancing act between maximum performance and cost reduction. The integrated software and hardware platform for controlling all process steps includes high-performance Beckhoff Industrial PCs, EtherCAT, a fast communication system, distributed I/Os, an extensive drive technology portfolio and TwinCAT automation software. Modular in design and precisely scalable in terms of performance requirements, PC-based Control is suitable both for controlling individual machines and for complete factory automation.

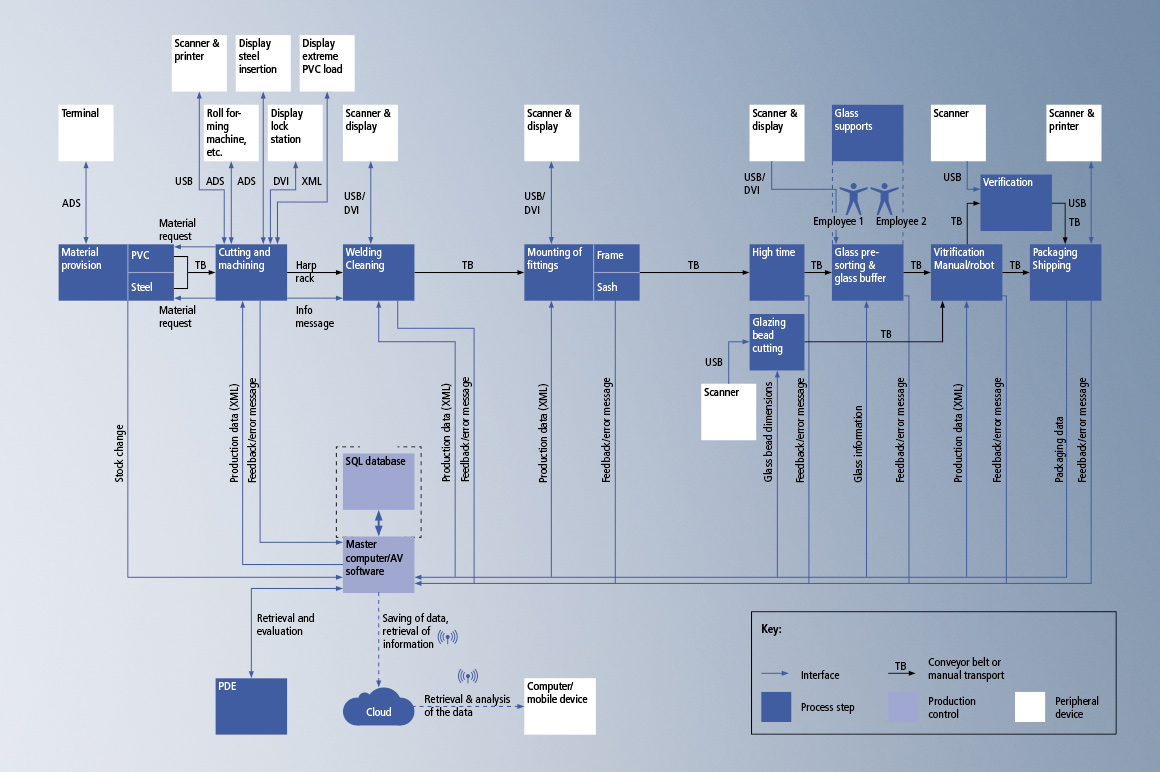

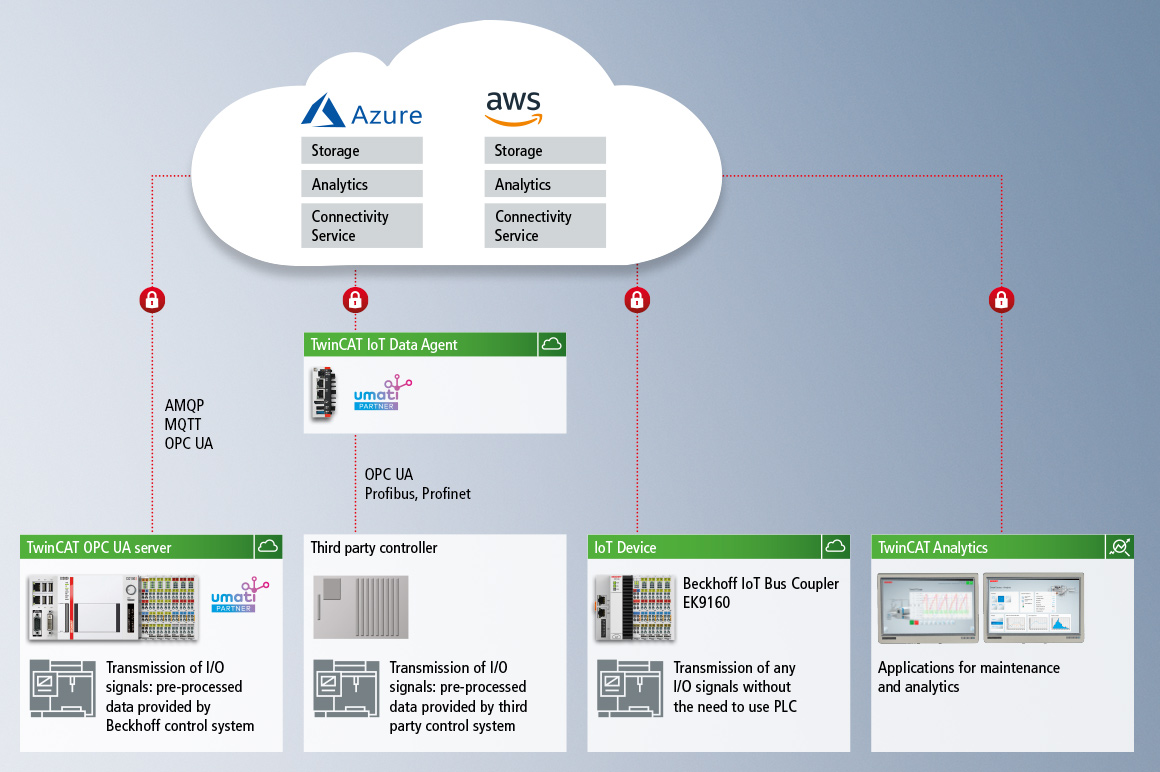

Thanks to high-performance processors, all machine and system functions, including PLC, motion control, CNC, robotics, HMI, vision, safety, measurement technology, cloud communication and analytics, can be mapped in software on a single platform. The open hardware and software interfaces offer a high degree of freedom for machine design and construction and enable machine manufacturers to integrate a wide range of different devices, including equipment from third-party manufacturers. On the one hand, this ensures the efficient interaction of all system components and thus maximum productivity. In addition, the consistent implementation of all functionalities in the form of software modules means that there is no need for additional controllers, which significantly reduces the hardware costs and the engineering effort. Support for all common fieldbus systems and software protocols guarantees consistent horizontal and vertical communication, from networking of individual machines with each other to the IT level and into the cloud.

The expertise acquired through decades of collaboration with machine manufacturers and end customers in the woodworking industry makes Beckhoff a reliable partner with exceptionally high solution competence. With PC-based control technology, Beckhoff provides complete automation solutions for plant and mechanical engineering – for new systems and for machine retrofits alike.

Our engineering department offers comprehensive application support:

- application project planning and documentation

- electrical engineering design with ECAD software

- PLC application programming

- visualization

- complete switchgear cabinet assembly according to customer specifications and standards, including

- configuration and location of components in the control cabinet

- EMC-compliant design

- air conditioning and ventilation

- equipment labelling

- logistics

- assembly and on-site commissioning

- complete process documentation

- implementation of special applications

- integration with supervisory control and MES systems

- integration into enterprise IT infrastructures