Beckhoff Smart System Diagnosis (B/SSD)

Real-time state monitoring of systems and rotary servomotors

Sedež Slovenija

Beckhoff Avtomatizacija d.o.o.

Real-time state monitoring of systems and rotary servomotors

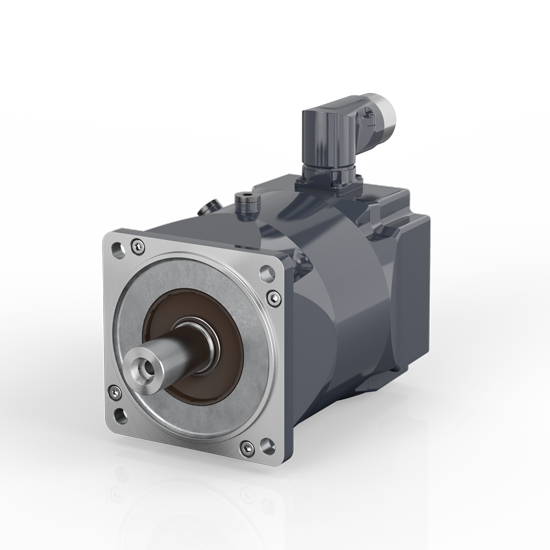

As an option, the AM8000/AM8300/AM8500/AM8700 and AM8800 series servomotors are available with the innovative Beckhoff Smart System Diagnosis. With B/SSD, it is possible to monitor the state of systems and servomotors in real time with minimal effort. Precise measurement of vibration, humidity and temperature directly in the motor provides the basis for statistical evaluation with TwinCAT Analytics and effective predictive maintenance. This allows machine conditions and processes to be monitored and any necessary action to be taken in a timely manner to ensure efficient operation and maximum machine uptime.

B/SSD uses the proven One Cable Technology (OCT), which eliminates the need for additional sensors and sensor cables and significantly reduces wiring work.

Thanks to full integration in TwinCAT Analytics, live data and historical data can be recorded, clearly visualized and processed into valuable information with B/SSD for machine optimization. Vibration measurements can be performed as an average value (RMS), with peak values (Peak-Peak) or statistically (Kurtosis) up to ±50g.

| Order reference | For AM80uv-wxyz and AM85uv-wxyz | |

|---|---|---|

| t | motor series | |

| u | flange code F | |

| v | motor length | |

| y = L | One Cable Technology for power and feedback: feedback transmission via motor cable, no feedback cable necessary, electronic nameplate, multi-turn, absolute position within 4096 revolutions, resolution 24 bit, SIL 2-capable (mandatory for TwinSAFE Safe Motion functions at AX8xxx-x2xx), Beckhoff Smart System Diagnosis (B/SSD) | |

| Information | The options cannot be installed in the field. | |

The TwinCAT Analytics product family offers a complete workflow for data acquisition, storage, analysis and visualization in dashboards.

The AM8000 synchronous servomotors with One Cable Technology are suitable for applications with the highest demands on dynamics, speed and performance.

The AM8300 synchronous servomotors with integrated water cooling are suitable for applications with extreme demands on performance and dynamics.

The AM8500 motors with OCT provide an increased moment of inertia for applications with extremely high requirements for synchronism and control quality.

The AM8700 motors combine the advantages of the highly dynamic AM8000 servomotors with the high requirements of the packaging and food industries.

The AM8800 motors are ideal for extremely harsh environmental conditions. The highest protection rating and stainless steel surfaces defy aggressive media.