Software tools and libraries for building automation

In order to make the engineering of applications in building automation as efficient and simple as possible, we have developed an extensive construction kit of software tools, libraries, and application samples. This is based on the free programming environment TwinCAT Engineering (TE1000). It allows programming according to IEC 61131-3 and gives the system user maximum flexibility in solving tasks.

The basic functions for the automation of all technical systems of building automation – from simple logic blocks and PID controllers to lamella setpoint tracing in relation to the sun’s position – are included in the TwinCAT 3 Building Automation library (TF8040). With the function blocks from the Building Automation library, system integrators have an extensive portfolio of ready-to-use applications, or “templates,” at their disposal. These are tried-and-tested and well-documented program blocks, ranging from applications in heating, ventilation, and air conditioning technology to the room automation functions of solar protection and lighting control. They simplify the system integrator’s familiarization with the system and ensure a high level of system functionality. This increases the quality of the execution as well as the reusability of the programs created.

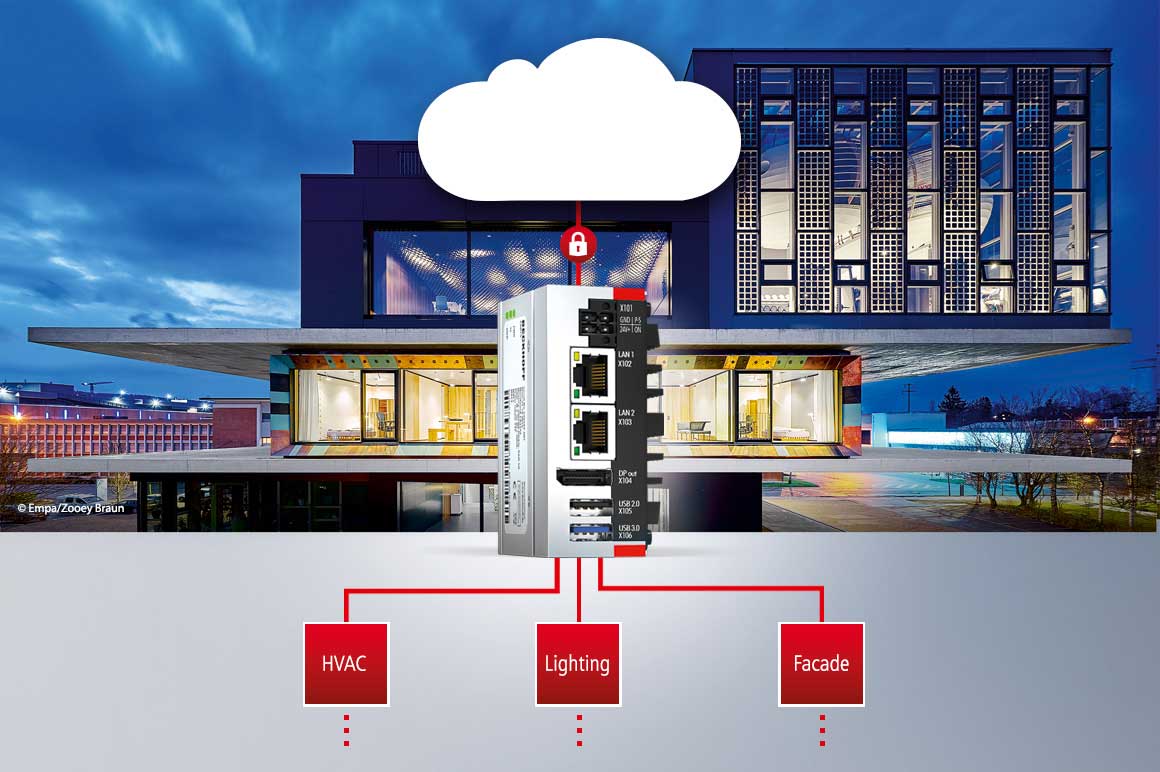

For the integration of the Beckhoff automation stations into the higher management and control level, the communication via BACnet and OPC UA is integrated directly into the templates. Depending on the desired communication protocol, the TwinCAT functions TwinCAT 3 OPC UA (TF6100) and TwinCAT 3 BACnet/IP (TF8020) are available for this.

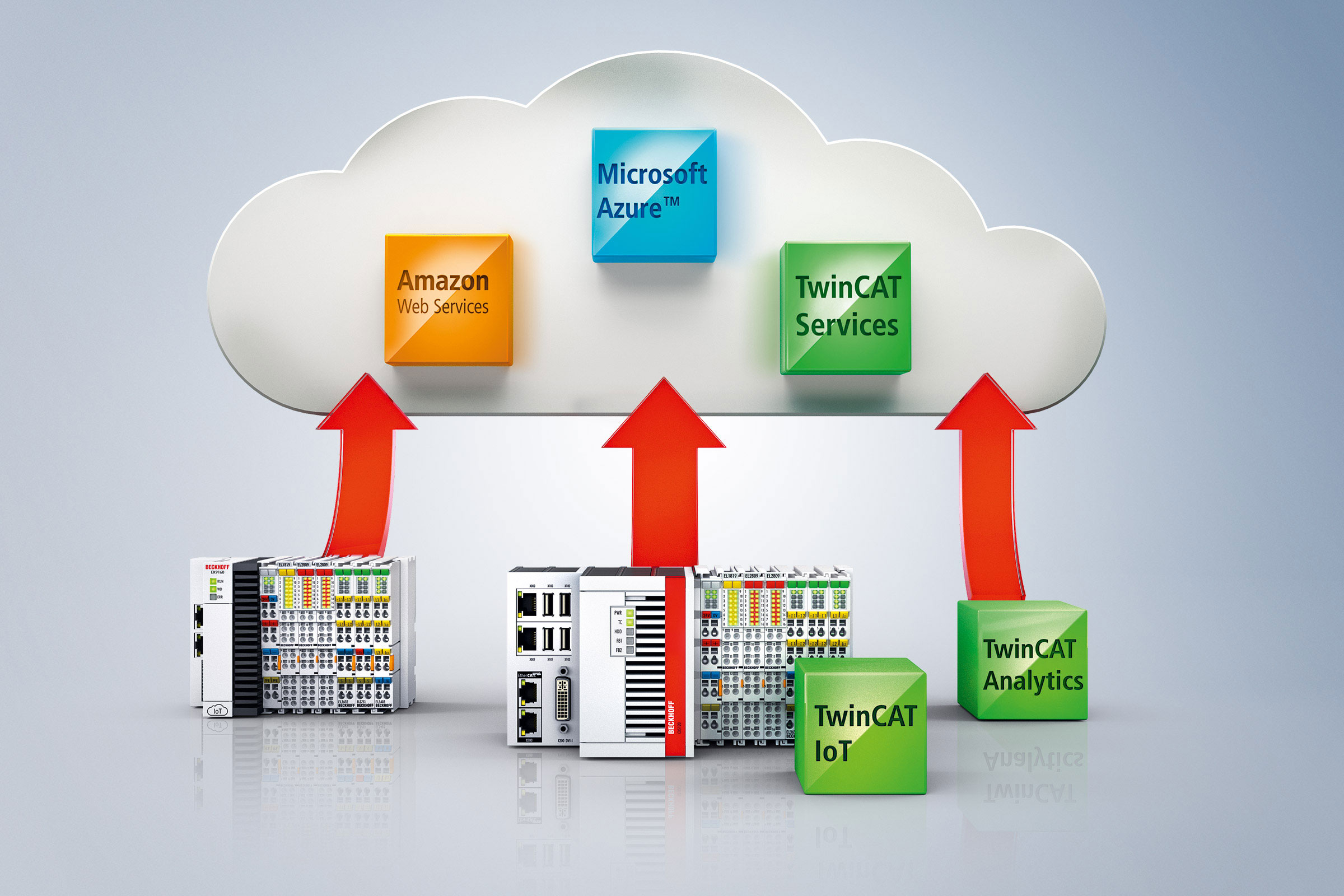

With the TwinCAT 3 IoT Data Agent (TF6720), the PC-based control platform is “ready for cloud.” It independently collects the process data configured for the purpose and transfers it to a communication or data service in the Microsoft Azure™ or Amazon Web Services (AWS) cloud; alternatively, it sends the process data to an MQTT or AMQP message broker.

The system operation and parameterization can be carried out on site on the control cabinet via touch panel or remotely by means of an integrated HTML5 web visualization. For higher demands regarding operating functionality and for support for web technologies, such as a responsive design, the software library TwinCAT HMI (TF2000) is recommended. It supports all basic operating and monitoring functions, such as system graphics, alarm and event lists, scheduling, and trends.