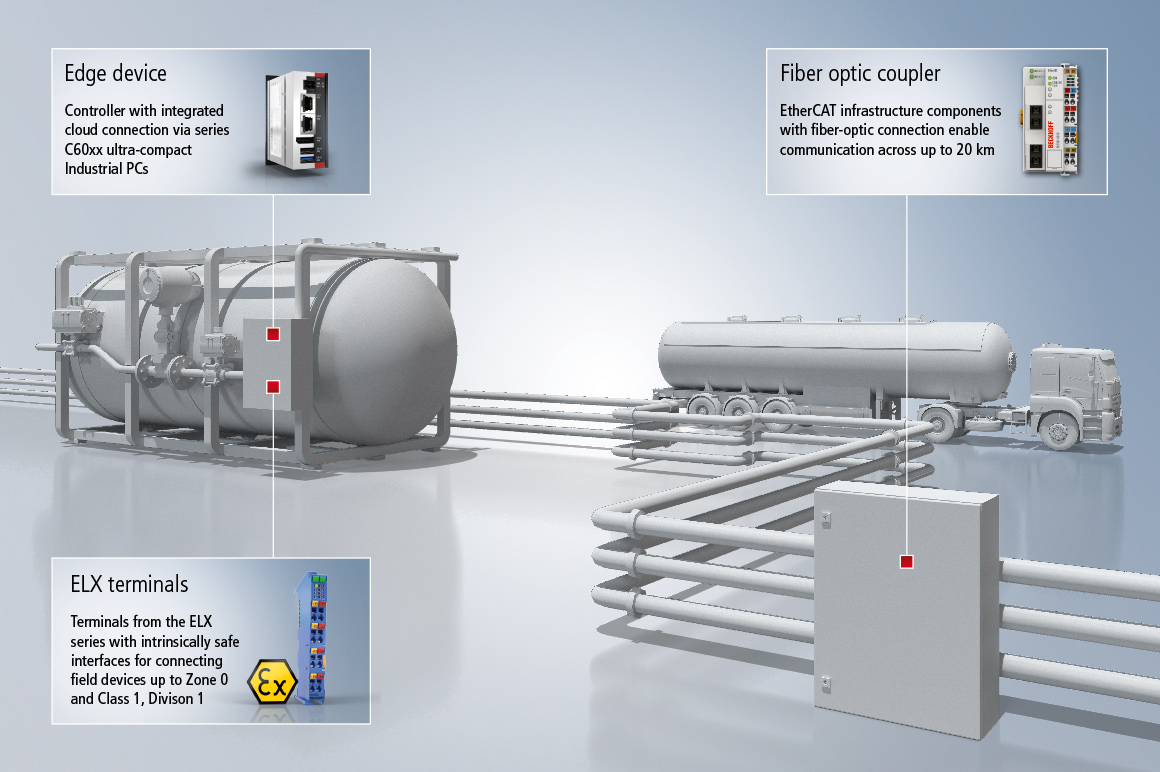

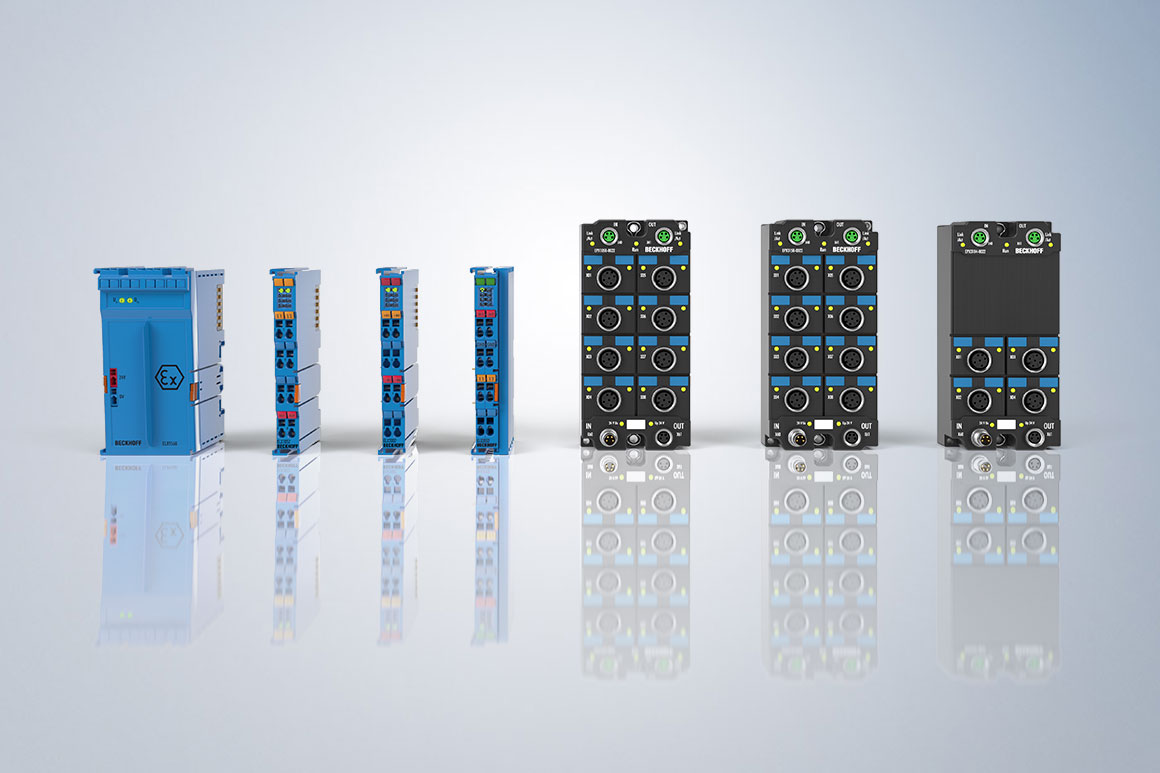

As an experienced partner of the wind and solar industries, Beckhoff is already working at the very origin of the hydrogen value chain – renewable power generation. Over 125,000 wind turbines have already been automated with our open PC-based control technology. What’s more, a large proportion of the solar panels installed throughout the world are produced with the aid of Beckhoff technology. Beckhoff also has many years of experience in process technology, as well as in the automation of applications with explosion protection requirements.

When hydrogen is put to use – for example as a fuel for vehicles, in fuel cells, or in combined heat and power plants – Beckhoff technology has already achieved success in a whole host of applications. In the future, hydrogen will need to be used as a sustainable alternative to fossil fuels in further areas: in methanation and generation of ammonia, in the production of e-fuels, and in numerous other forms of technology that are currently still being researched. PC-based control is being deployed here, too, and is helping to reduce carbon emissions through the use of green hydrogen.