Beckhoff’s extensive range of technologies and products underscores its position as a highly experienced partner and solution provider for a wide variety of assembly and handling processes. Countless customers are already leveraging PC-based control to develop and implement their innovative solutions and ensure they maintain a technological edge.

Current applications

Flexible final inspection: XPlanar greatly increases testing capacity and throughput

In the fall of 2021, Beckhoff began to completely rethink the way it carried out final inspections of I/O components. Its aim was to significantly increase testing capacity and throughput, even though many different types of terminals are produced. The system, which was created by the company’s own Equipment Manufacturing department, can program, adjust, and test around 10,000 terminals per shift fully automatically. The high speed and flexibility are the result of not only the sophisticated system concept, but also the intelligent XPlanar transport system, PC-based control, and the wide range of EtherCAT Terminals.

Sophisticated, highly efficient production line thanks to PC- and EtherCAT-based servo drive technology

Mitec Enginy, a young and dynamic automation integrator based in northern Spain, says it has developed a sophisticated and powerful production technology masterpiece. The core element is a revolutionary motion control system with a total of 67 servo axes synchronized by a camming function. The result is a production line that feeds, cuts, and bends wire, produces springs, and mass-produces the final product – a rat trap – in just 1.5 seconds. In addition to the servo drive technology, Beckhoff also supplies the required control performance with the CX2062 Embedded PC and TwinCAT software.

Intelligent microassembly product transport: modular machine design and highly accurate positioning with XTS

In its search for a high-precision transport system for fully automated electronic module assembly systems, the Dutch company IMS found just what it was looking for at Beckhoff. With a repeatability of 10 µm, the XTS linear transport system meets the high requirements for product positioning. In addition, the XTS modular system provides the basis for easy modular adaptation of the plant to changing production requirements.

Machine concept for the production of brooms and brushes: distributed servo drive technology and EtherCAT P facilitate production process overhaul

Industrial production of brooms and brushes is essentially the same as the classic manual approach; only the machinery simply works faster. Nevertheless, it’s still not fast enough for Italian machine builder Borghi S.p.A. This is where the Moon project came in, allowing the company to make a significant leap in terms of productivity. The project saw the development and implementation of a completely new production sequence using PC-based control and the AMP8000 distributed servo drive system based on EtherCAT P.

XTS enables parallel inspection processes for maximum throughput with a minimized footprint

Gefasoft has developed an exceptionally compact testing system for the optical inspection of automotive airbag diffusers using the intelligent transport system XTS. The individual movement of the XTS movers enables individual inspection processes to be duplicated and executed in parallel. As a result, the workstations are utilized optimally and the total number of workstations is reduced. Overall, this leads to a 40% reduction in the required footprint.

Application reports

- 20.03.2025 | Application report

Automatic preassembly speeds up prefabricated homebuilding

Promise Robotics, CanadaImagine a world where affordable, sustainable housing isn't a dream, but a reality. This vision faces two significant hurdles: skyrocketing construction costs and a shortage of skilled labor. Enter Promise Robotics, a Canadian startup reinventing prefabrication as they say: Advanced automation technology from Beckhoff and artificial intelligence (AI) control a robotic solution for efficient prefabrication. As a result, on-site assembly becomes up to 70% faster.

- 16.07.2024 | Application report

Intelligent transport system brings agility to product handling

JR Automation®, United StatesInitially geared toward hygienic manufacturing in the life sciences market, the powerful FlexChassis® platform offers enormous potential for application in other industries. These include food and beverage, semiconductor, automotive, battery and e-mobility, e-commerce and more. Here, adaptive automation via the eXtended Transport System (XTS) from Beckhoff Automation is key, according to the experts at JR Automation.

- 16.07.2024 | Application report

Premium finish with professional finesse

Lesta, ItalyA perfect surface finish is the most obvious sign of a high-quality component. Achieving this consistently throughout series production is a challenge many manufacturers face, and this prompted Lesta srl, an Italian company, to develop its innovative painting robots. Flexibly automated with PC-based control from Beckhoff, these robots are suitable for use in a wide range of painting tasks, making a crucial contribution to optimizing the surface-finishing process.

Application videos

17.11.2023 | Multimedia

Syntegon: Product handling platform with Vision and XPlanar

Syntegon, a global supplier of process and packaging technology for the food and pharmaceutical industries, presented a product handling platform at Interpack 2023 for secondary packaging. XPlanar for product transport and Vision hardware optical quality control form the core of this platform.

26.04.2023 | Multimedia

Application example with XPlanar: Production plant for bus terminal manufacturing

Here, a terminal can be tested and programmed in three seconds. This results in an output of 1,200 bus terminals per hour. Or, if you strung them all together, a 10-meter long terminal segment. Find out which automation technology is behind this flexible and powerful production plant in Beckhoff I/O production and see what else it can do in this video.

21.08.2020 | Multimedia

XTS enables parallel inspection processes for maximum throughput with a minimized footprint

Gefasoft has developed an exceptionally compact installation for the optical inspection of diffusors for airbags via eleven camera stations requiring varying inspection times. With the help of the highly flexible eXtended Transport System, Gefasoft was able to run individual inspection processes in parallel and optimize the product output.

19.02.2020 | Multimedia

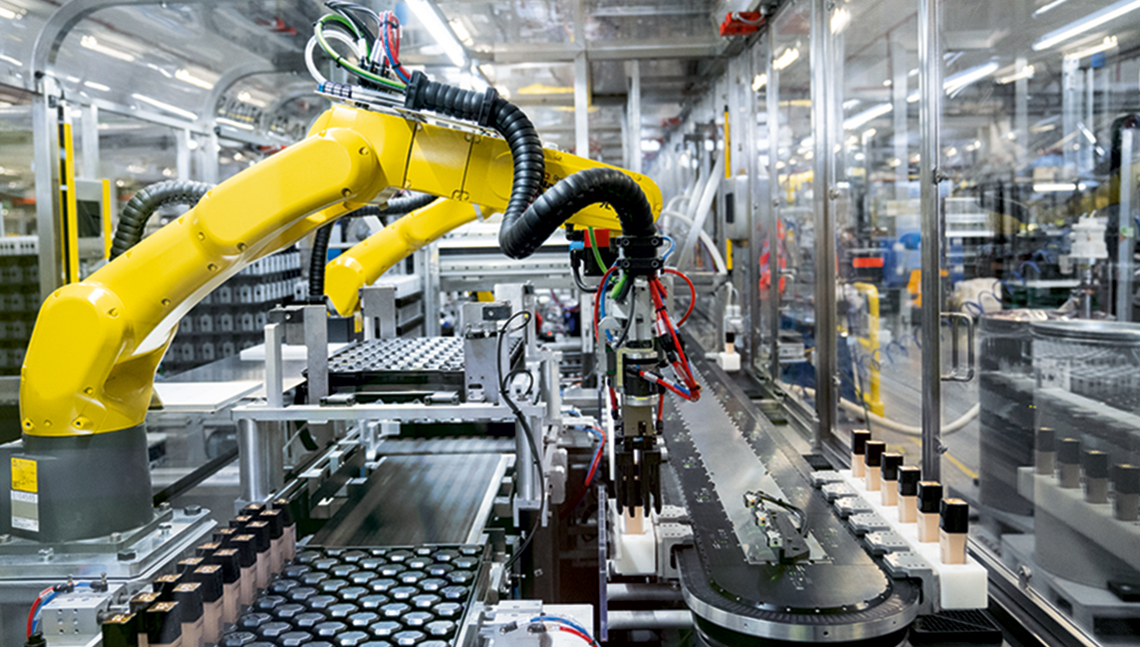

L’Oréal/Secad, France: XTS increases flexibility and reduces system footprint in cosmetics filling

In its Caudry plant in the French Département Nord, the L’Oréal Group produces high-quality skin care products, mascaras and make-up foundations for its Division Luxe. Three of the production lines are already based on the eXtended Transport System (XTS) from Beckhoff. This includes the new Agile F24 filling and capping line, which enables fast format changes with a simultaneously increased output, in line with the corporate strategy to increase the agility of its production operations. In addition, the new system combines the functionality of five previously separate machines on a reduced footprint.