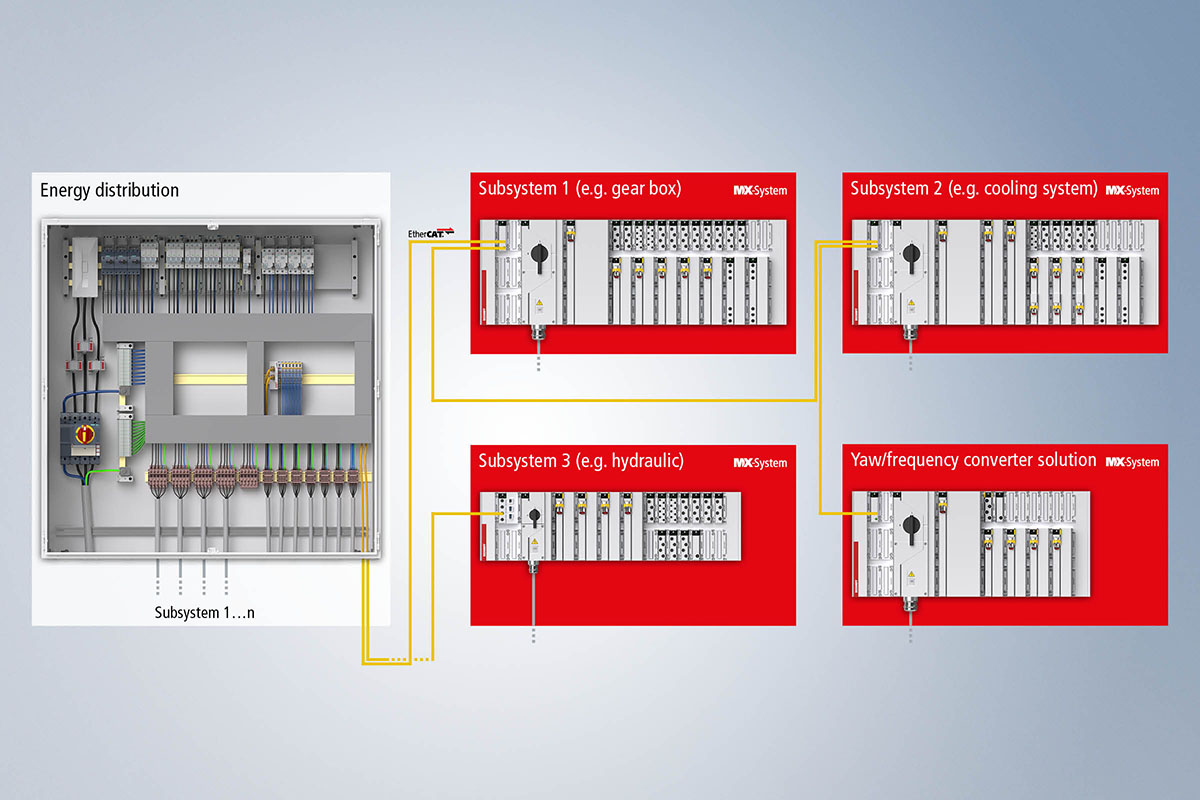

Control cabinet-free automation with the MX-System

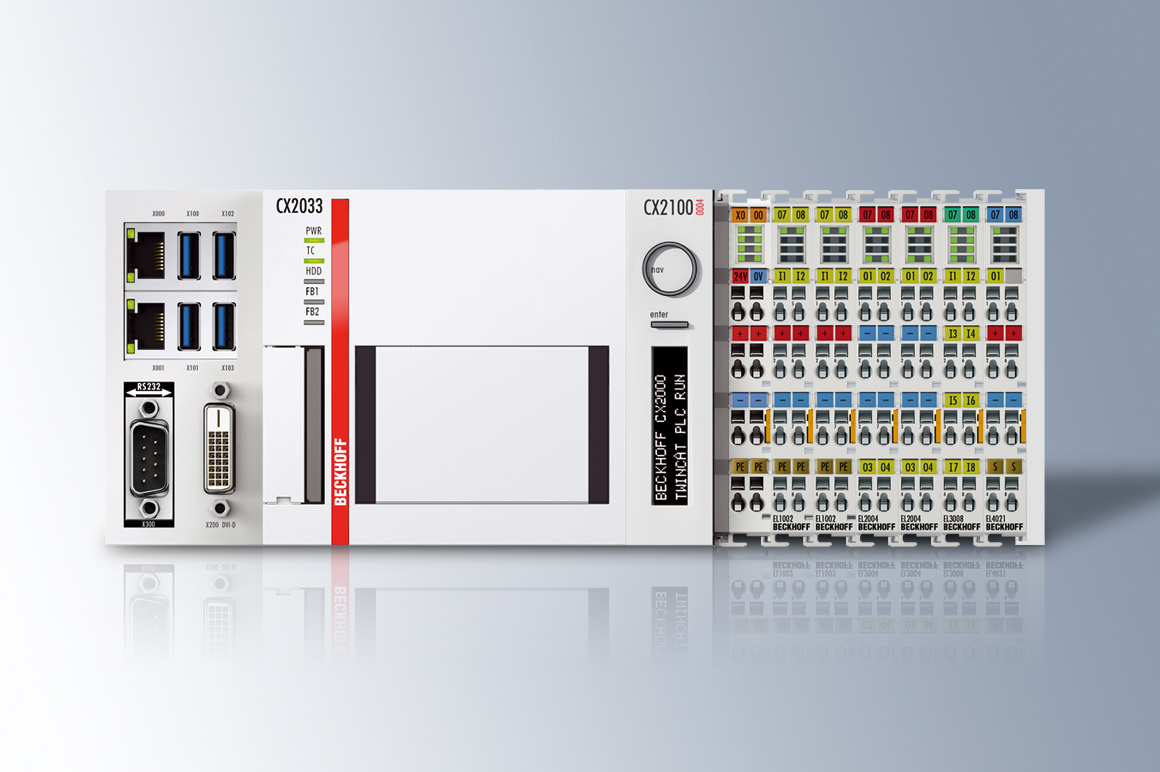

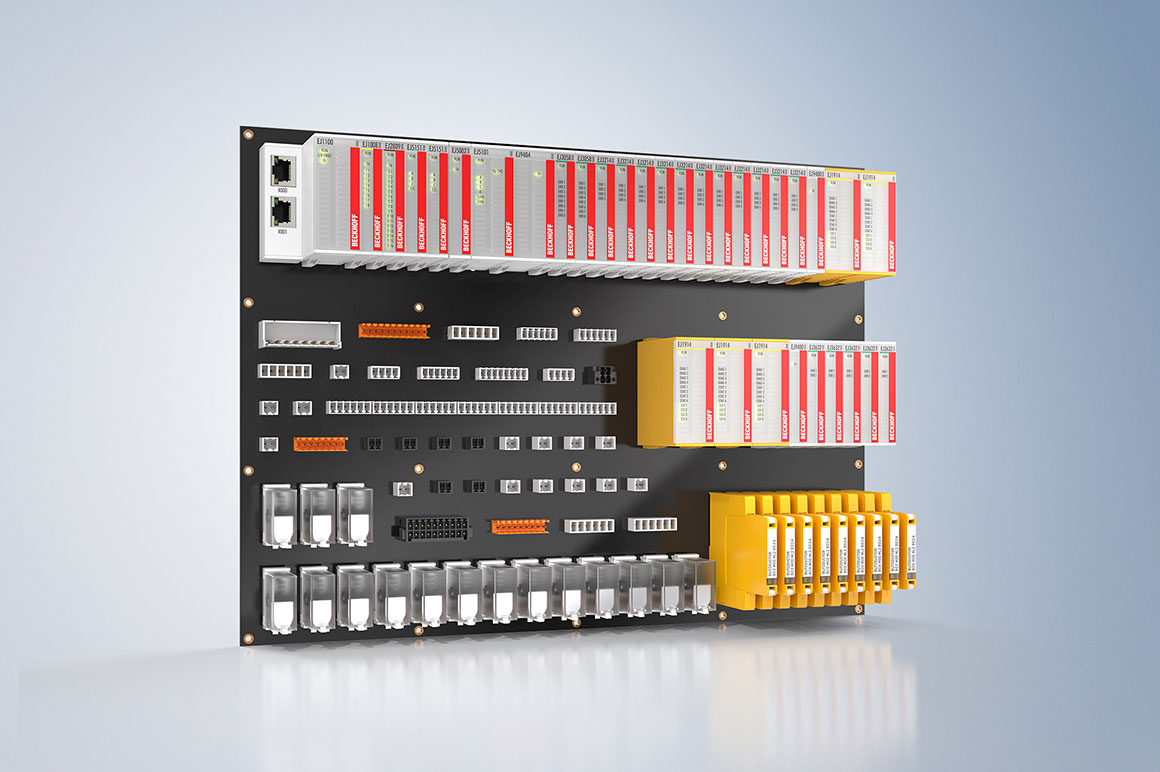

For the first time, the MX-System enables completely control cabinet-free automation solutions in machine and system engineering. The combination of baseplate and function modules resulting from the modular system combines all the tasks and features of a control cabinet: power supply, fuse protection and distribution, generation and monitoring of auxiliary voltages, sequence control with inputs and outputs, control of motors and actuators, and the connection level for the field devices. The full system integration of all machine functionalities is achieved via freely selectable IPC, coupler, I/O, drive, relay, and system modules, which can be configured and combined according to the specific application.

The consistently systemic approach of comprehensively coordinated assemblies, certified to international standards, enormously reduces the effort required for planning, assembly, machine installation, and maintenance. Since considerably fewer components are required than in traditional control cabinet design to implement the same requirements, the entire MX-System is significantly more compact than previous solutions. The system footprint is reduced, and system availability and flexibility are also increased. In each life cycle phase of a control system, the MX-System offers significant advantages over the classic control cabinet.