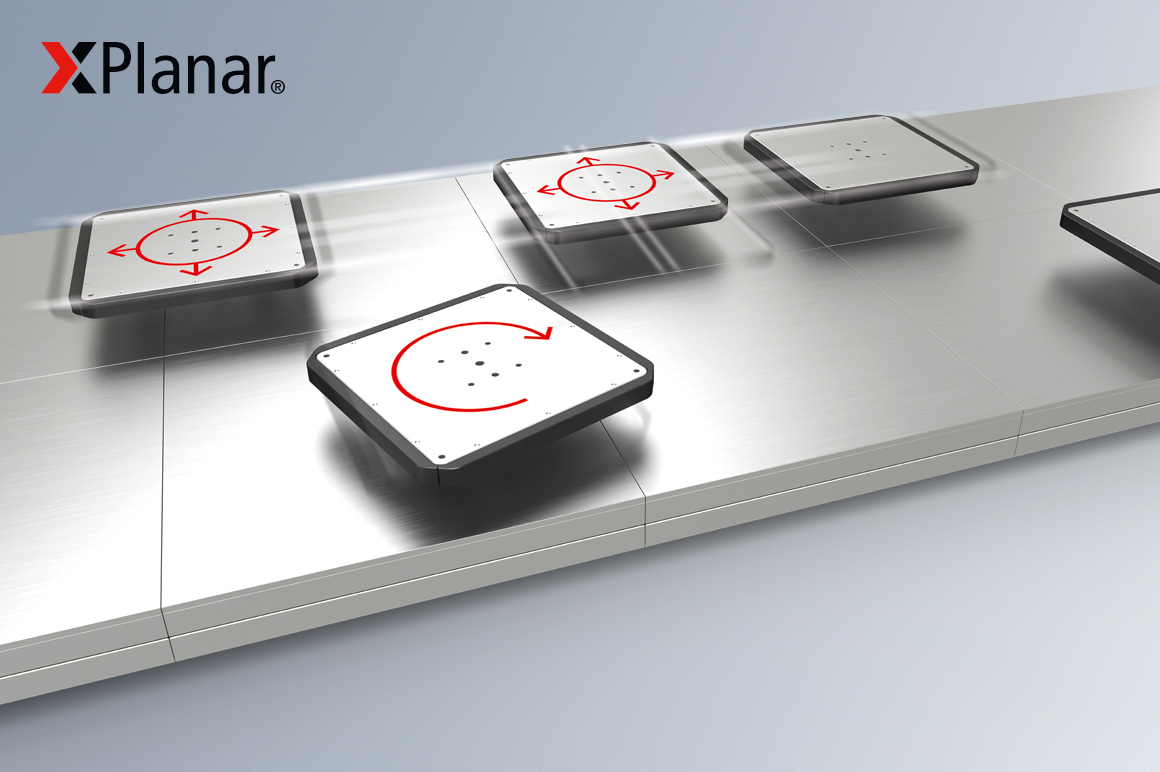

Automatic part removal and integrated handling are widely used in modern plastics production plants. High flexibility and a short removal time with minimal mounting space are the demands that plastics processors place on the transport and handling systems. On account of its long-standing cooperation with high-performance injection molding machine manufacturers, Beckhoff offers an interesting product range, especially for fast parts removal and in-mold labeling. However, Beckhoff also offers innovative solutions for conventional injection molding: from linear, Cartesian handling to articulated robots. These and other special kinematics can be programmed with the TwinCAT Kinematic Transformation software tool. An extensive portfolio of servomotors and drives with scalable performance and in various form factors provides performance-oriented solutions for the various handling weights with a minimal footprint.

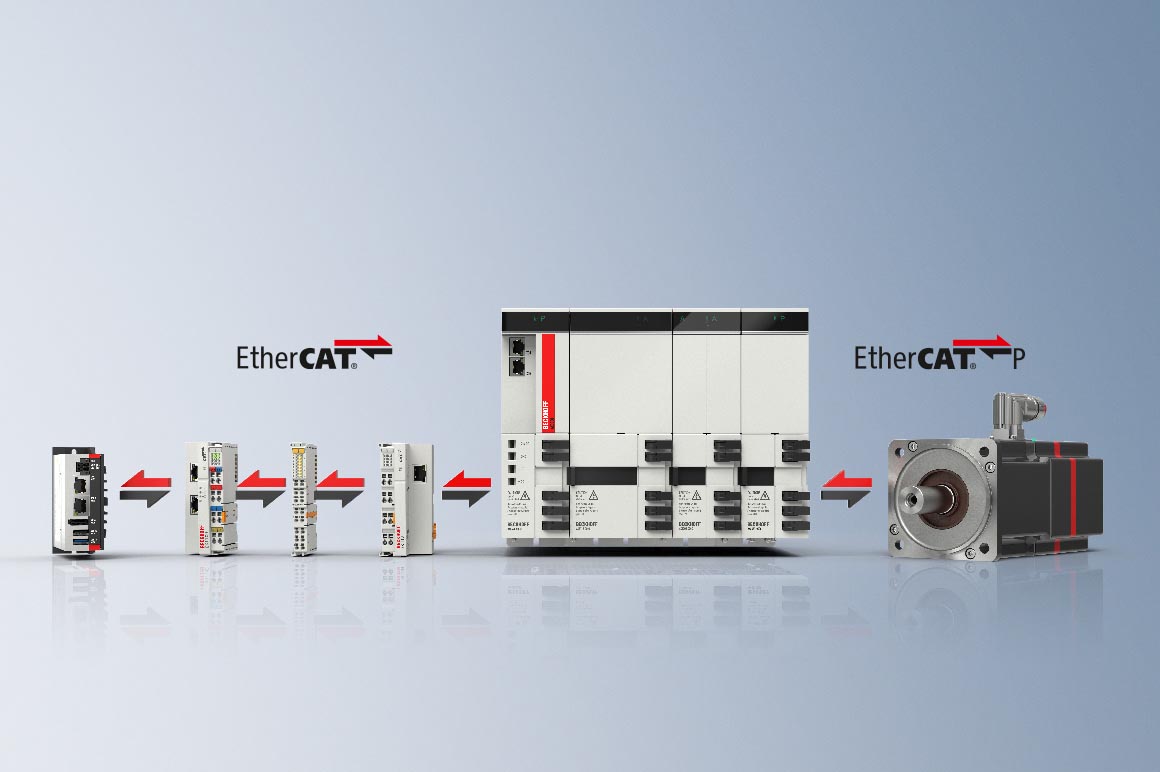

The Beckhoff servomotors from the AM8000 series are based on the One Cable Technology; this simplifies wiring for the machine manufacturer and saves costs for flexible cabling in drag chains. The EtherCAT fast fieldbus technology, combined in a single cable with the power supply of the motors, reduces the control cabinet space requirement to zero.

The EtherCAT Box modules are suitable for decentralized data acquisition on robot arms. Special detection functions, such as pneumatic pressure monitoring for the gripper elements, are optimally tailored to handling applications. For cost-effective applications, Beckhoff offers the EtherCAT Box modules in the version with D-Sub connectors; the cabling for the power supply is additionally saved by using EtherCAT P.

The high requirements for the flexibility of handling equipment, combined with ever-increasing standards for machine safety, are perfectly covered with the Beckhoff safety products. The machine manufacturer benefits from Beckhoff's many years of experience in safety technology. The development of the Safety over EtherCAT (FSoE) protocol dates back to 2005. The decentralized safety components simplify design and commissioning in different machine environments. For example, they are ideal for monitoring protective doors and light barriers. Certified safety function blocks are available with TwinSAFE, the safety technology integrated in the TwinCAT engineering workbench. They enable flexible configuration of the system components on site, adapted to the customer's requirements. TwinSAFE includes all important safety functions for use in handling equipment, such as the Safely Limited Speed or the safe monitoring of the brakes in the drive motors.

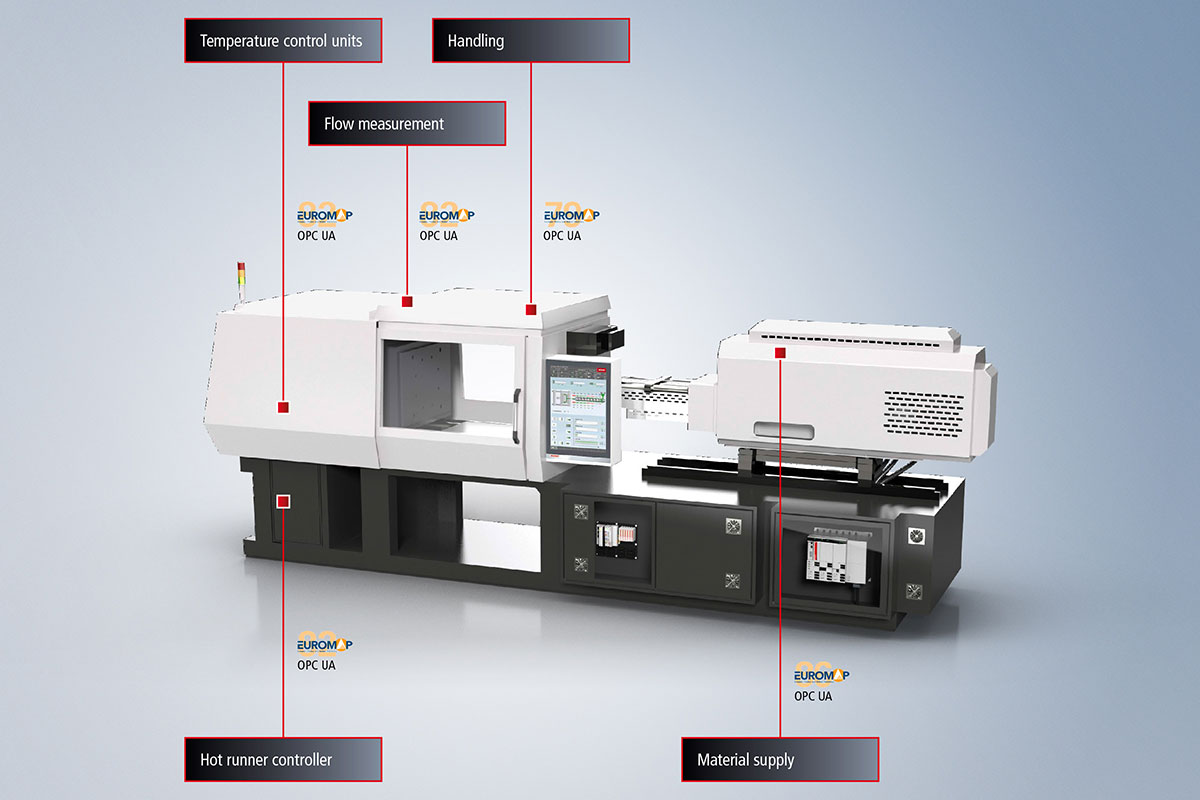

Beckhoff offers the well-known Euromap 67 interface for communication with the injection molding machines. For the future OPC UA-based interface Euromap 79 (OPC 40079), Beckhoff offers a powerful engineering tool in TwinCAT; the machine manufacturer can assign the data points quickly and easily to the Euromap objects. In addition to the OPC UA-based Euromap interfaces, Beckhoff strongly recommends the use of EtherCAT as a deterministic fieldbus connection between injection molding machine and handling for time-critical processes such as robot synchronization in high-performance injection molding.

Beckhoff technologies and components optimize handling processes

© Engel

Optimized handling of plastic parts

Linear handling systems are widely used in particular in combination with injection molding machines. They are characterized by a sturdy, simple design and are suitable for a wide range of different handling weights. The requirements for removal systems on the part of plastics processors are: the lowest possible footprint for control cabinets, simple programming and the integration of the user interfaces of mobile panels into the controller of the injection molding machine. In addition, the machine manufacturer wishes to map its modular design in hardware and software with the help of cost-effective solutions. Standardized Euromap interfaces as well as a fast fieldbus should enable use in the entire range of plastic parts production.

Beckhoff meets these requirements with a wide range of hardware and software products:

- EtherCAT as a fast Ethernet-based fieldbus for I/Os and drive technology

- TwinSAFE as a safety-oriented architecture for I/Os and drives: drives are placed in a safe operating state with Safety over EtherCAT. Functions such as safely limited torque or safely limited speed enable setup processes in the working area.

- EtherCAT Box modules in IP67 with cost-effective D-Sub connection technology

- EtherCAT Box modules with special functions for robots, such as pressure monitoring on grippers or integrated acceleration measurement

- EtherCAT P as a single-cable solution for connecting EtherCAT Box modules and motors with an integrated servo drive

- motors with OCT (One Cable Technology) for reducing the costs of drag chain-compatible cables on the moving axes

- AX8000 multi-axis servo system supports modular machine concepts for the full range of different handling weights.

- distributed servo drive from the AMP8000 series for machine designs without a control cabinet

- compact, distributed servo drive in 48 V technology from the AMI812x series for low handling weights

- drive technology terminals in an IP20 version for applications with very low part weights or auxiliary axes

- cost-effective solutions through scalable CPU power: from the Embedded PCs from the CX7000, CX90xx and CX5xxx series for simple applications, e.g., with pneumatic axes, to complex, interpolating systems

- ultra-compact Industrial PCs from the C60xx series for space-saving installation in the control cabinet

- programming with TwinCAT, the universal engineering environment, with powerful motion control functions and with support for various cloud protocols

- Euromap 67 interface for digital signal exchange

- EtherCAT for fast synchronization with the processing machine

- TwinCAT HMI for HTML5-based visualization with different end devices

Short cycle times of machines and removal units

Especially in packaging injection molding, fast parts removal and integrated decoration (in-mold labeling) are a growing market. Productivity, i.e. short cycle times of machines and removal units, is crucial for market success in this processing segment. Beckhoff has been supplying high-performance controls for Husky injection molding machines for many years and thus has extensive experience in high-performance injection molding systems with extremely short cycle times.

Beckhoff meets these requirements with a wide range of hardware and software products:

- EtherCAT as a fast Ethernet-based fieldbus for I/Os and drive technology

- EtherCAT P as a single-cable connection for EtherCAT Box modules and motors with integrated drive

- motors with suitable drive power with up to a standstill torque of 92 Nm

- motors with OCT (One Cable Technology) for reducing the costs of drag chain-compatible cables on the moving axes

- drives from the AX5000 series for the main axis and as two-channel drives for the secondary axes in IML applications

- AX8000 for modular designs in different sizes and performance classes

- drive technology terminals in an IP20 version for auxiliary axes, e.g., with IML

- TwinSAFE as a safety-oriented architecture for I/Os and drives

- powerful PC platforms in the execution as Embedded Controllers from the CX52xx or CX20xx series or the C60xx series of ultra-compact Industrial PCs

- programming with TwinCAT, the universal engineering environment, with powerful motion control functions and with support for various cloud protocols

- Euromap 67 interface for the traditional digital signal exchange with the injection molding machine

- EtherCAT for fast synchronization with the machine in high-performance applications

- Euromap 79 interface based on OPC UA

- TwinCAT HMI for HTML5-based visualization with different end devices

Programming of PLC and robotics in one engineering environment

Articulated robots are used in blow molding machines, among other things, to guide the extruded hose; in injection molding applications they are used, for example, for handling large parts in small workspaces. Since the robots cooperate in the production environment with injection molding machines on the one hand and with other downstream stations on the other, simple integration with fast data communication is crucial for the cell productivity.

EtherCAT is often used in articulated robots as the standard for fast internal communication. This allows the Beckhoff hardware and software to be perfectly integrated into the environment of the articulated robots. Beckhoff supplies the corresponding software interfaces for KUKA and Stäubli robots according to the vendor-specific data exchange procedures based on EtherCAT: mxAutomation for KUKA KR-C4 robots and uniVAL PLC for Stäubli robots.

As a consistent software platform, TwinCAT enables the programming of PLC and robotics in one engineering environment. During operation, travel commands to the robot and actual positions are transmitted in real-time. The entire Beckhoff I/O portfolio is available for the integration of articulated robots into different production environments: from simple digital I/Os and safety-related monitoring to measurement technology or image processing. This makes the articulated robot part of Beckhoff's TwinCAT "ecosystem".

The following products from Beckhoff are particularly interesting for applications in the environment of articulated robots:

- I/O components in an IP20 or IP67 version

- TwinSAFE as a safety-oriented architecture for I/Os and drives

- EtherCAT Box modules with special functions for robots, such as pressure monitoring on grippers or integrated acceleration measurement

- EtherCAT Box modules with cost-effective D-Sub connection technology

- Euromap 67 interface for the traditional digital signal exchange with the injection molding machine

- EtherCAT for fast synchronization with the machine in high-performance applications

- TwinCAT technology functions according to the mxAutomation standard

- TwinCAT technology functions according to the uniVAL-PLC standard

- Euromap 79 interface based on OPC UA