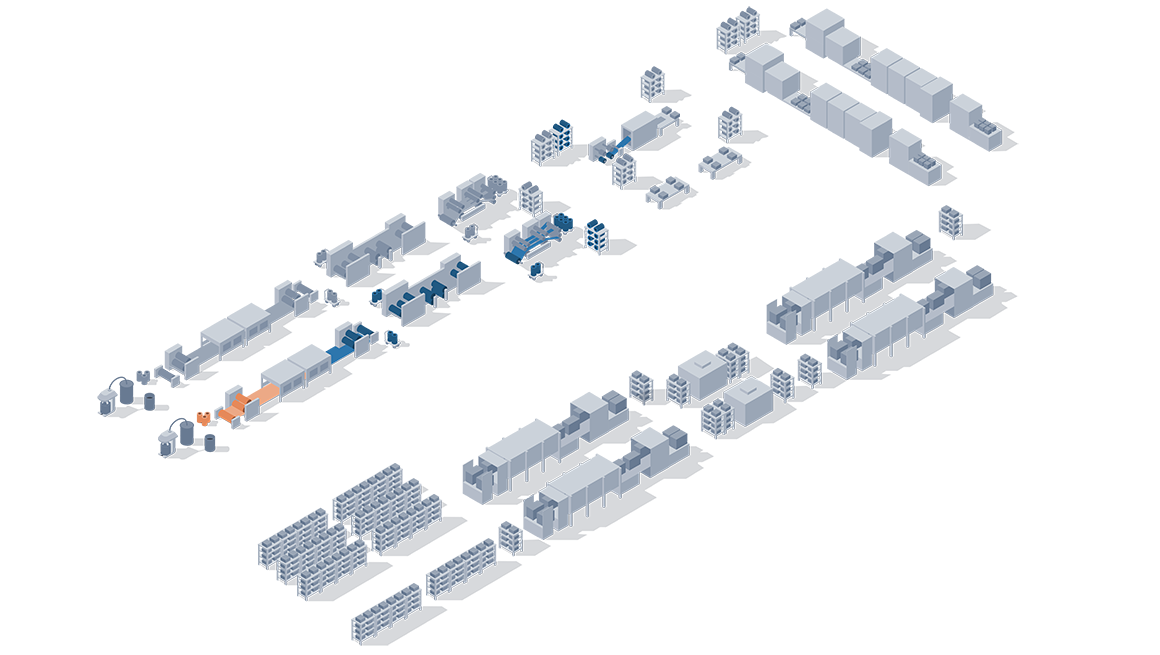

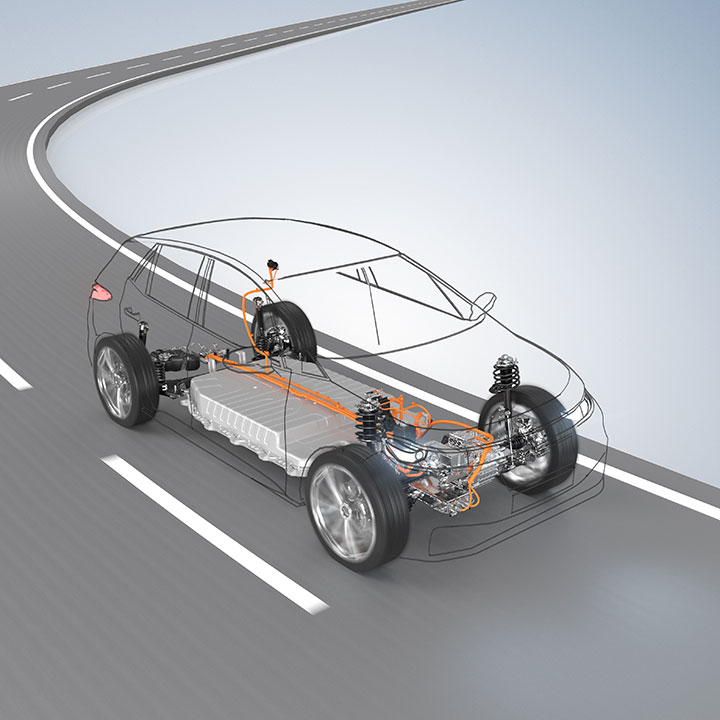

The fast-growing e-mobility market places high demands on battery cell production in terms of speed and efficiency. This is why intelligent, high-performance automation solutions are so essential. Our control technology enables end-to-end automation of all processes in battery manufacturing: from electrode production to module and pack assembly. PC-based control offers advantages for all machine types, no matter whether you produce round, pouch, or prismatic battery cells. We offer the perfect solutions for all forms of battery technology too: from lithium-polymer cells to solid-state battery cells to LFP cells.

Your head start in battery manufacturing with Beckhoff:

- high speed thanks to fast cycle times

- optimal synchronization of control functions on a single platform

- execution of sophisticated motion tasks

- flexible scalability of hardware and software

Control technology for all battery manufacturing processes

Implemented worldwide: Beckhoff in battery manufacturing and e-mobility

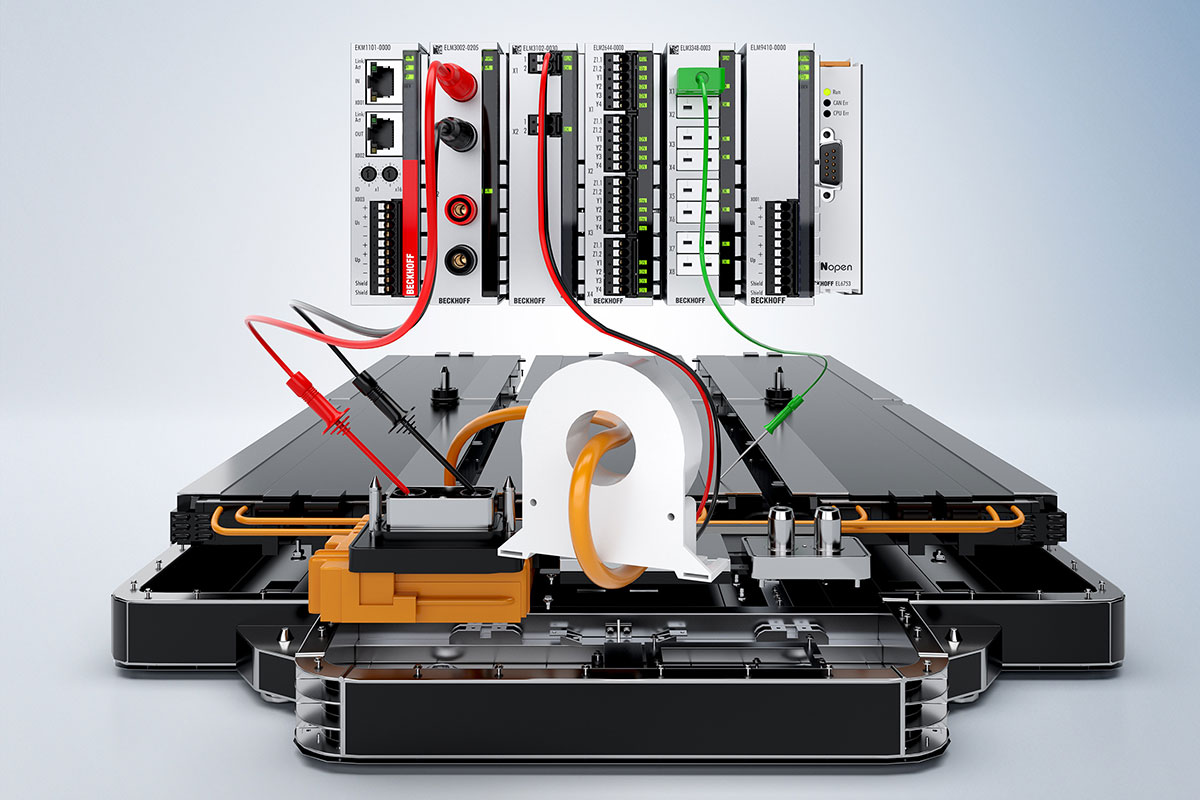

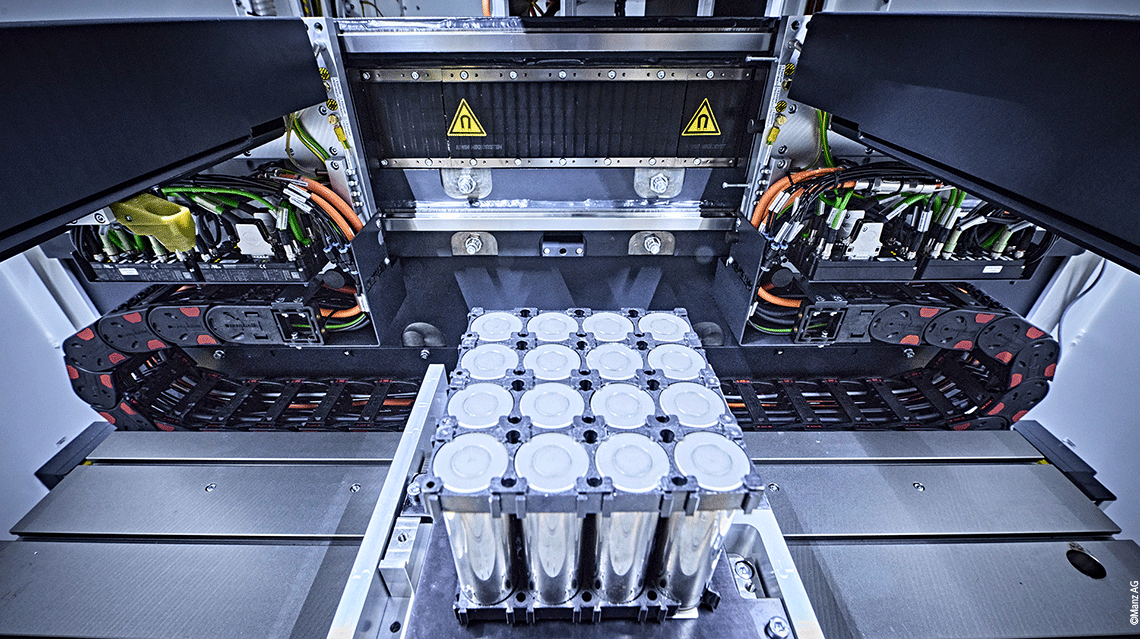

Automation for highly precise and efficient production of lithium-ion battery modules

The rapidly growing electromobility market calls for particularly efficient manufacturing processes when it comes to the production of lithium-ion battery systems. This is where the BLS 500 laser welding system from Manz makes for an ideal solution, as it allows individual battery cells to be precisely contacted and connected to form battery modules. A high level of efficiency is ensured by means of a graphical programming tool and a virtual commissioning tool from Manz, as well as rapid PC-based control technology from Beckhoff and the continuous OPC UA communication this facilitates.

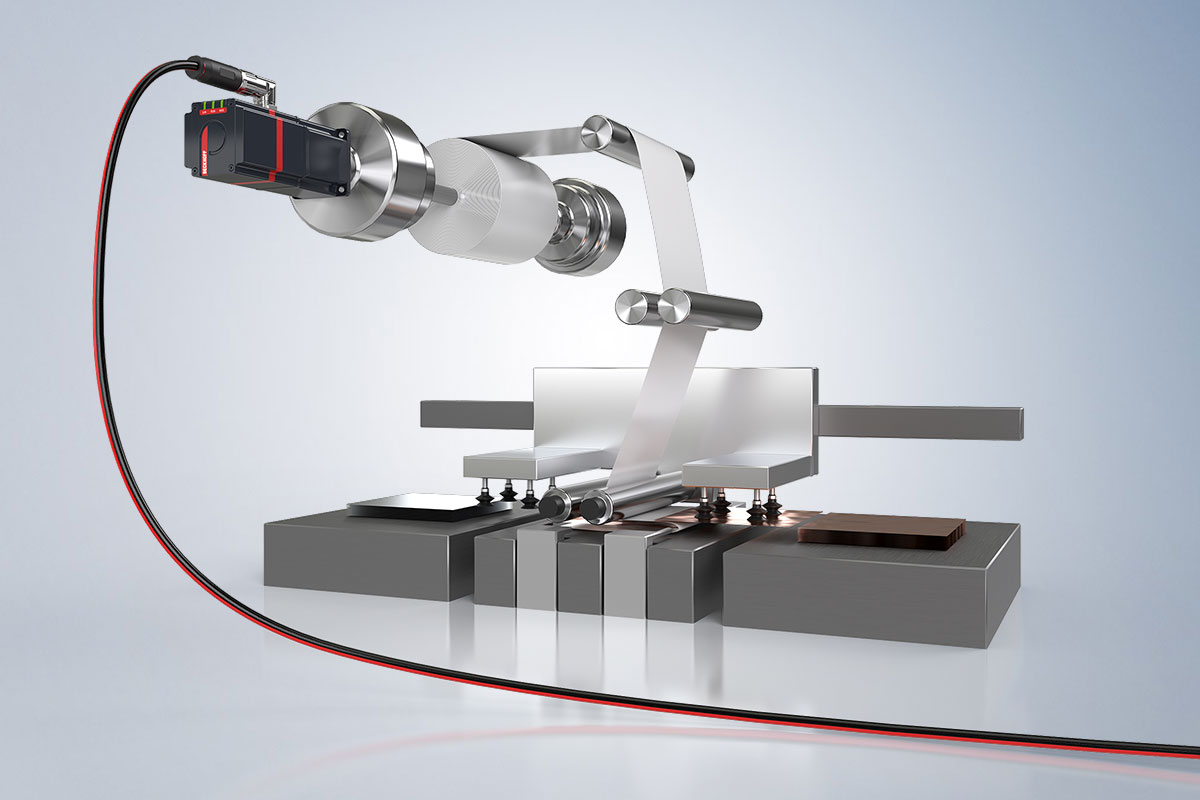

Linear transport system eliminates slow pick-and-place process

Low-cost lithium-ion battery cells (LIB) are the key to mass electromobility, although the manufacturing process has always been a cost driver – until now. Researchers at TU Berlin are using continuous Z-folding to replace the traditional pick-and-place movements that have been used so far, thereby accelerating battery cell production. The XTS linear transport system from Beckhoff has played a crucial role here.

Special purpose automation solutions for the automotive and battery industries

S4 Integration, a South African company, provides special purpose end-to-end solutions in industrial automation and software for the automotive and energy storage industries. Shaun Erasmus, their customer engagement manager, discusses their work with Beckhoff in this video.

Further information

Automotive industry

PC-based control from Beckhoff supports modern manufacturing concepts for the mobility of the future.

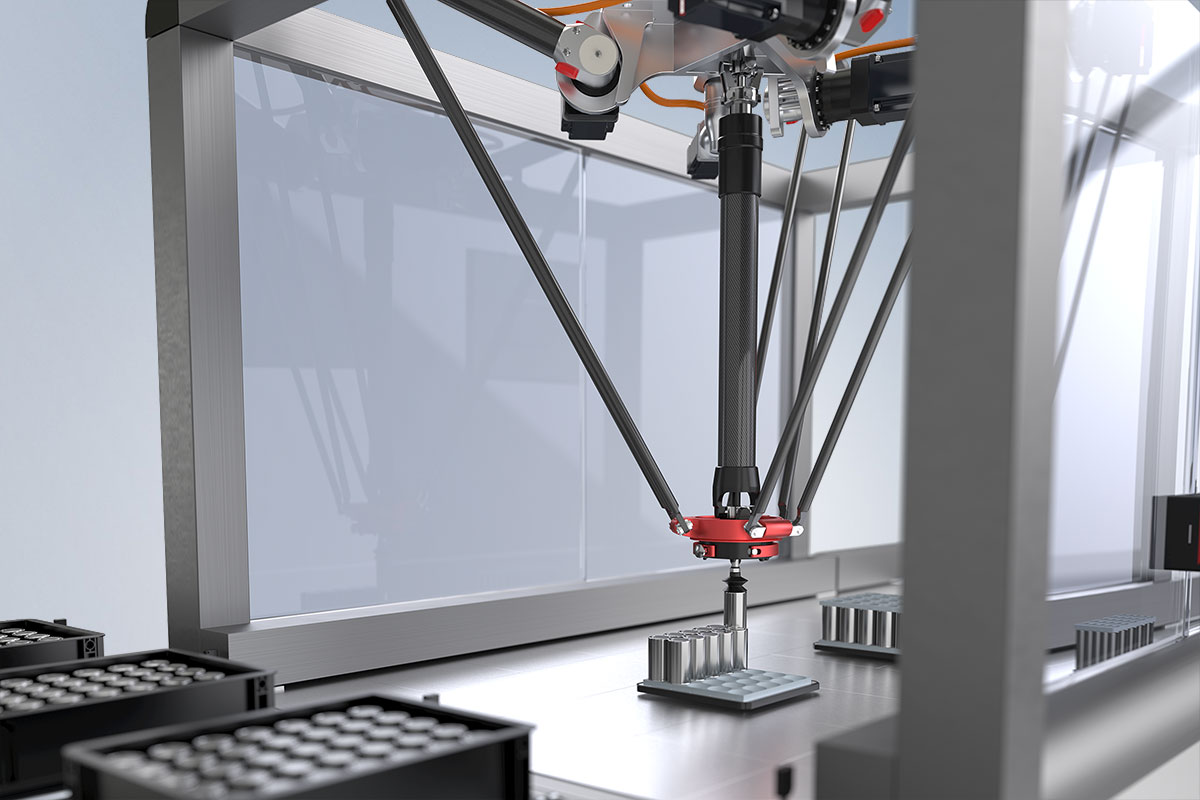

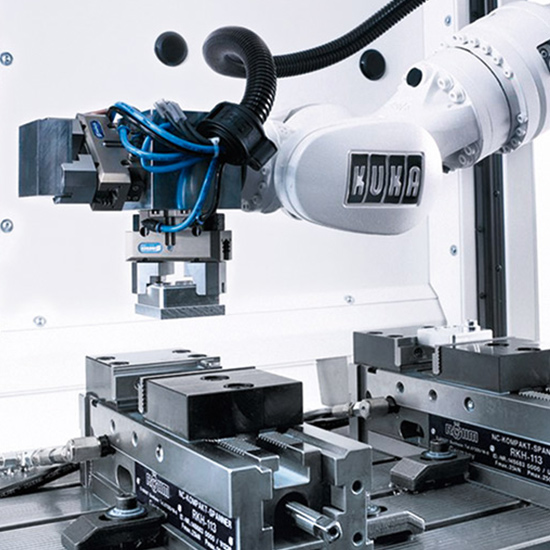

Assembly and handling technology

PC-based control technology from Beckhoff optimizes the entire process chain: from handling, production, and assembly to testing, control, and management.