Products

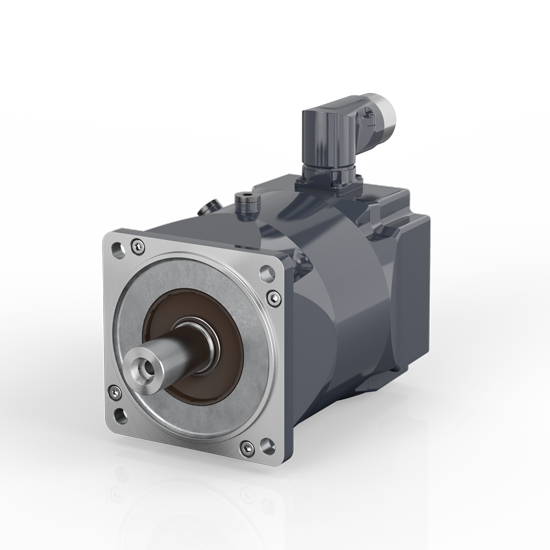

AM8000 | Servomotors

The AM8000 synchronous servomotors with One Cable Technology are suitable for applications with the highest demands on dynamics, speed and performance.

AM8300 | Servomotors with water cooling

The AM8300 synchronous servomotors with integrated water cooling are suitable for applications with extreme demands on performance and dynamics.

AM8500 | Servomotors with increased rotor moment of inertia

The AM8500 motors with OCT provide an increased moment of inertia for applications with extremely high requirements for synchronism and control quality.

AM8700 | Servomotors with anodized housing

The AM8700 motors combine the advantages of the highly dynamic AM8000 servomotors with the high requirements of the packaging and food industries.

AM8800 | Stainless-steel motors with hygienic design

The AM8800 motors are ideal for extremely harsh environmental conditions. The highest protection rating and stainless steel surfaces defy aggressive media.

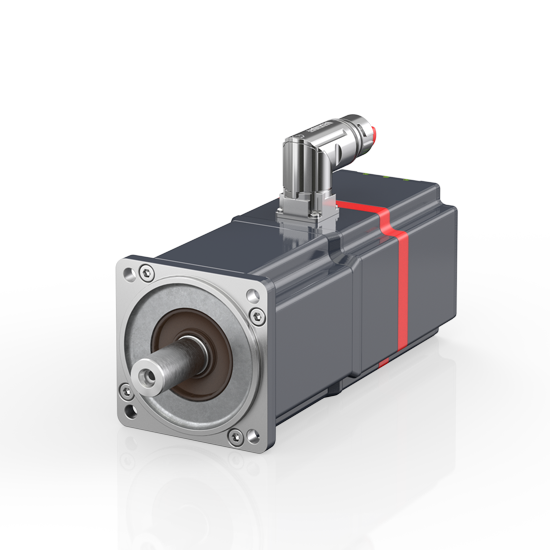

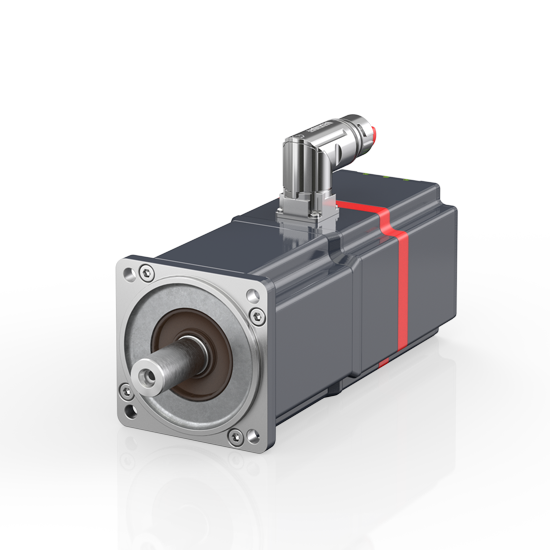

AMP8000 | Distributed servo drives

Synchronous servomotor with integrated servo drive for the realization of modular machine concepts without a control cabinet.

AMP8500 | Distributed servo drives with increased rotor moment of inertia

AMP8500 for the realization of modular control cabinet free machine concepts with high requirements on synchronism and control quality.

AM8100 | Servomotors for compact drive technology

The AM8100 motors are specially designed for operation with the compact drive components in the smallest of mounting spaces.

AMI8100 | Compact integrated servo drives

Synchronous servomotor with integrated servo drive for the realization of machine concepts without a control cabinet in the low voltage range.

Software

The motion software products optimally support the selection and commissioning of suitable hardware components for drive solutions.

Rotary servomotors for positioning tasks with the highest demands on dynamics and performance

The highly efficient rotary servomotors offer the perfect solution for every application. The motors are available either with innovative One Cable Technology (OCT) or with a classic 2-cable standard.

Highly dynamic and flexible

The AM8000 synchronous servomotors are characterized by high dynamics, energy efficiency, and reduced life cycle costs. Seven sizes and up to four stack lengths cover all power ranges. On request, the AM8000 motors are also offered with a third-party cooling system to increase power. The motors are available with different windings, which are optimally matched to the Beckhoff AX5000/AX8000 servo drives. Due to the sophisticated modular system, mechanical adaptations can be implemented quickly. Different ordering options for encoders, holding brakes, and connection options leave no wishes unfulfilled. Cross profiles and rotatable Speedtec connectors allow quick installation.

With the AM8500 series, the servomotor range is extended by a complete series with an increased rotor moment of inertia. With the integrated OCT safety encoders and a resolution of 24 bits, applications with the highest precision and synchronization requirements can be implemented. Depending on the requirements, the motors can be equipped with additional options for higher protection ratings. With the data programmed as standard in the encoders, the natural cogging can be enormously reduced, which enables perfect concentricity at low speeds.

The AM8300 series expands the servomotor portfolio to include a modular motor series with integrated water cooling. Due to its efficiently integrated water cooling, the AM8300 achieves an extremely high power density, allowing it to deliver up to 40 kW of power within a very compact space, depending on its size. Compared to convection-cooled motors, the power output increases many times over.

Motors in hygienic design

The AM8700 series with anodized housing make use of the advantages of the AM8000 series in relation to dynamics and performance. Due to the hygienic design, the motors are easy to clean and conform to a high IP protection rating without derating compared to the standard motor. The AM8800 stainless steel motor series is the optimum solution for use in extreme environmental conditions. Connection technology, a fully potted stator, and a stainless steel surface in a hygienic design meet the high requirements of the packaging and food industry in terms of dynamics and cleaning capability.

Compact solution

In the low voltage range, the AM8100 devices are perfectly matched to the Beckhoff servo I/O range. Together with the AM8100 motor series, the EL72xx servo terminals or the EtherCAT Box modules from the EP72xx series form an extremely small, highly dynamic servo axis. The AM8100 with OCT and multi-turn absolute encoder are suitable for precise positioning applications.

Decentralized and versatile

The AMP8000 consists of a combination of the proven AM8000 servomotors and a highly efficient servo drive. The integrated secure single-turn or multi-turn encoders enable the AMP8000 to be used in applications where functional safety is required. In the compact drive technology product sector, the AMI8100 combines a servomotor with a servo drive and an EtherCAT interface in a space-saving design for all motion requirements in the power range up to 400 watts. As an EtherCAT slave, the AMI8100 can be placed directly on the machine without a control cabinet and without an upstream I/O level, which makes it possible to create compact and modular control cabinet-free machines.

Predictive maintenance

As an option, the AM8000/AM8300/AM8500/AM8700 and AM8800 series servomotors are available with the innovative Beckhoff Smart System Diagnosis (B/SSD). With B/SSD, it is possible to monitor the state of systems and servomotors in real time with minimal effort. Precise measurement of vibrations, humidity, and temperatures directly in the motor provides the basis for statistical evaluation with TwinCAT Analytics and effective predictive maintenance. With full integration in TwinCAT Analytics and the proven One Cable Technology (OCT), B/SSD can be integrated into any system with minimal effort to ensure efficient operation and maximum machine availability.

Supplementary and intuitive

An extensive and optimally matched range of accessories completes the rotary servomotor portfolio. The drive system around the servomotor is completed with pre-assembled cables, flanges, and planetary gear units. The motion software products optimally support the selection and commissioning of suitable hardware components for drive solutions.