Precisely controlled stress tests increase availability

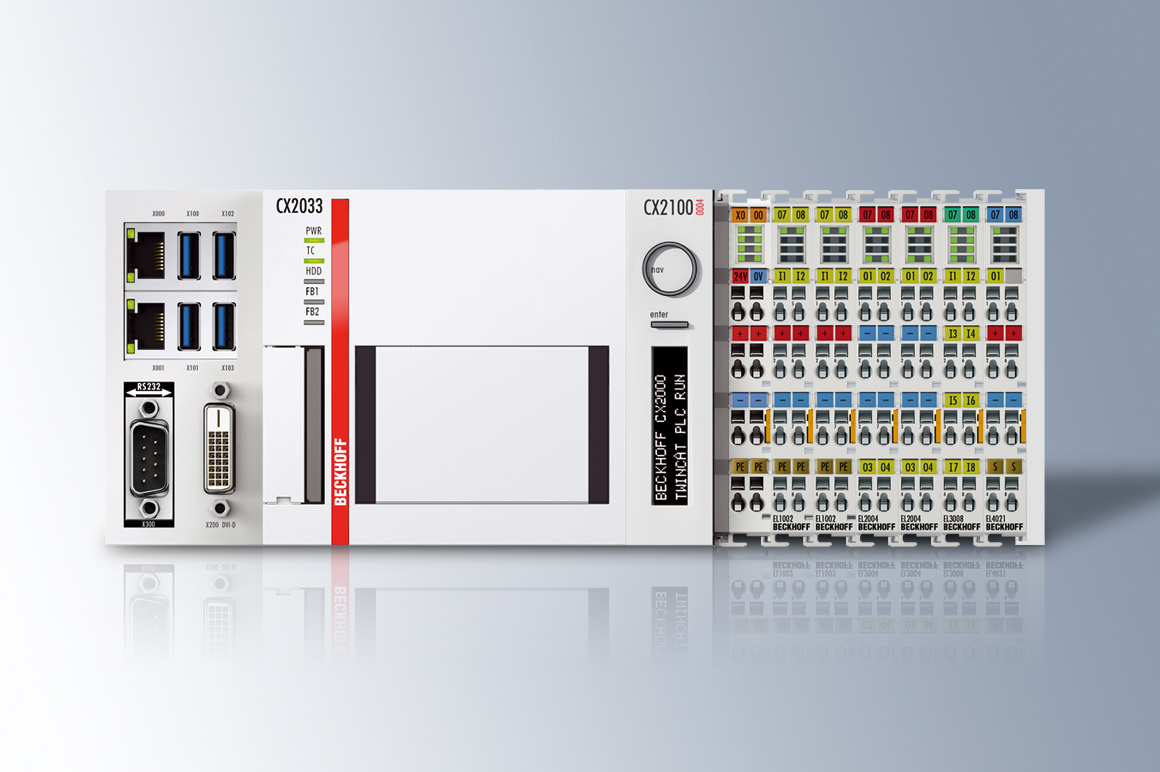

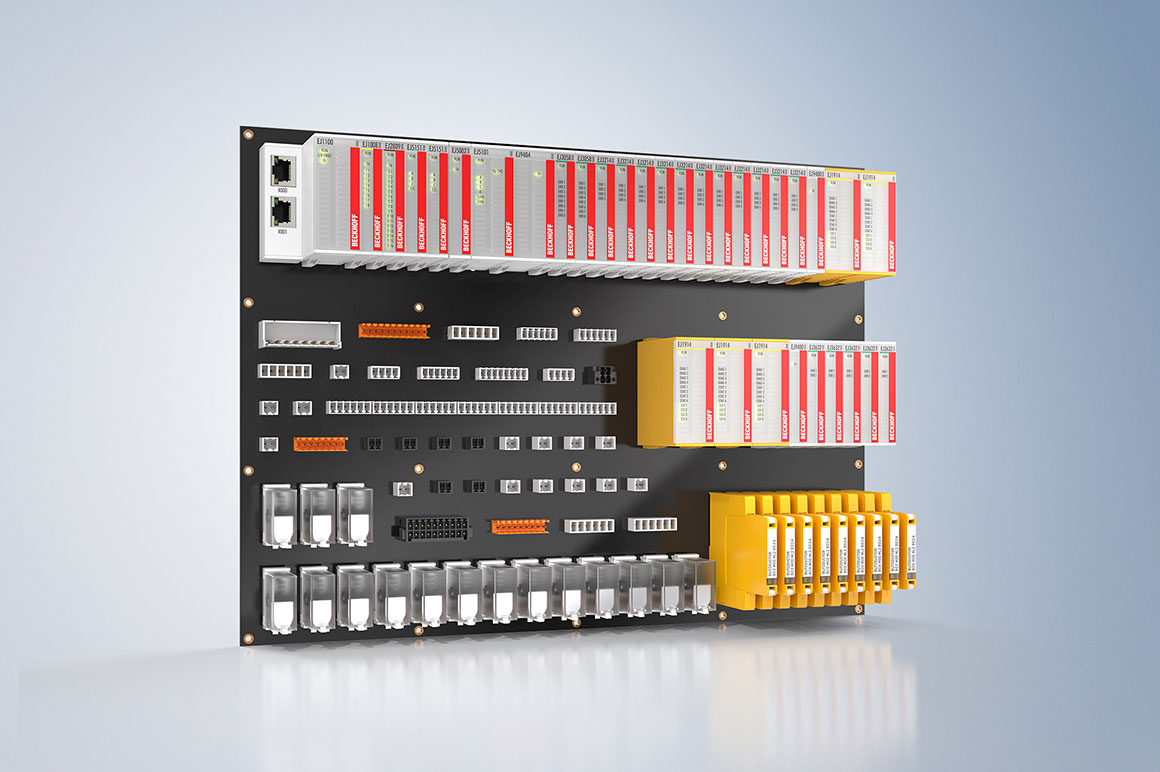

Beckhoff automates test bench for wind turbines

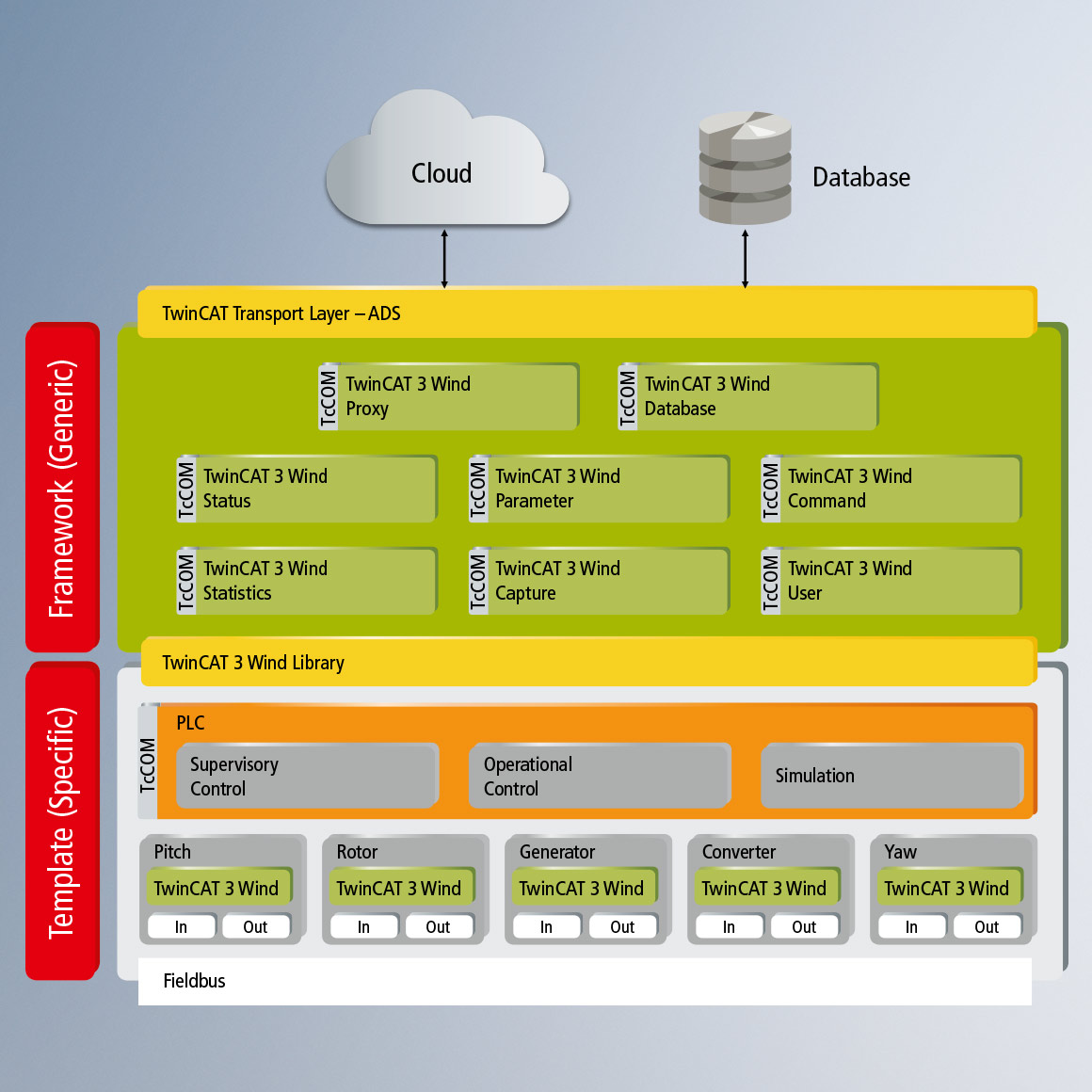

Online fault diagnostics improve wind turbine availability

Goldwind, China

Installation of wind turbines in any weather

Fast control technology reliably compensates for rotor blade movements caused by wind load

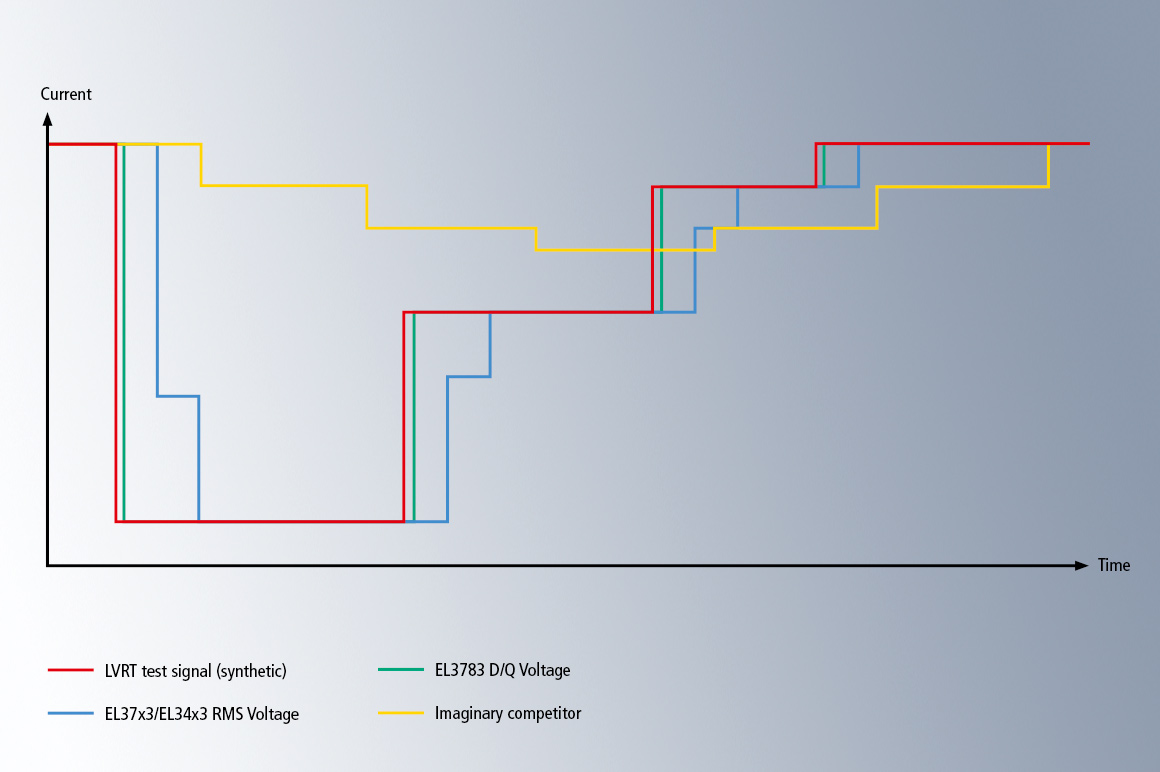

Precisely controlled stress tests increase availability

Beckhoff automates test bench for wind turbines

Online fault diagnostics improve wind turbine availability

Goldwind, China

Installation of wind turbines in any weather

Fast control technology reliably compensates for rotor blade movements caused by wind load

Precisely controlled stress tests increase availability