TwinSAFE: the integrated control and safety solution

In TwinSAFE, Beckhoff has implemented a universal safety concept that integrates safe functionalities into the standard control platform: from the PLC to I/Os to drive technology. All safety functions such as emergency stop, safety door monitoring, two-hand operation, safety mat evaluation and muting, safe position, safely limited speed, etc. can be programmed and configured on the integrated TwinCAT engineering platform. Safety technology is seamlessly integrated into the terminal segment via the TwinSAFE I/O modules, whereby safe signals can be mixed with standard signals as required.

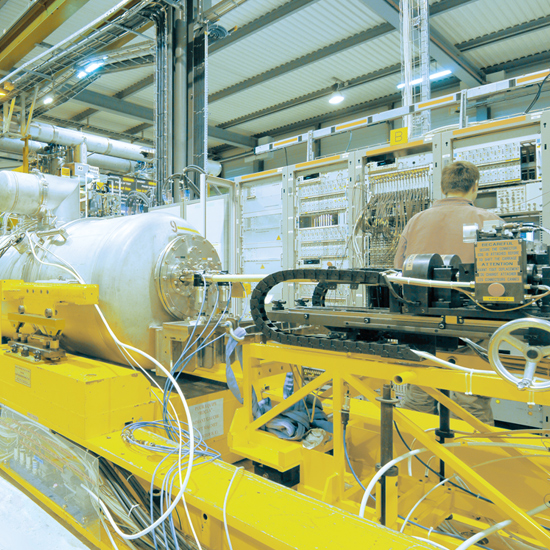

The typical safety functions can be programmed or configured according to the safety requirements in a TwinSAFE Logic Terminal, e.g. EL6910 or the EK1960 compact safety controller on the basis of standard safety function blocks. All Beckhoff safety controllers are suitable for applications up to SIL 3 according to IEC 61508 or Performance Level e of ISO 13849-1. The safety controllers support complex, safe analog evaluations, e.g., for the safe limitation of process variables such as pressures, temperatures or speeds of frequency-controlled drives.

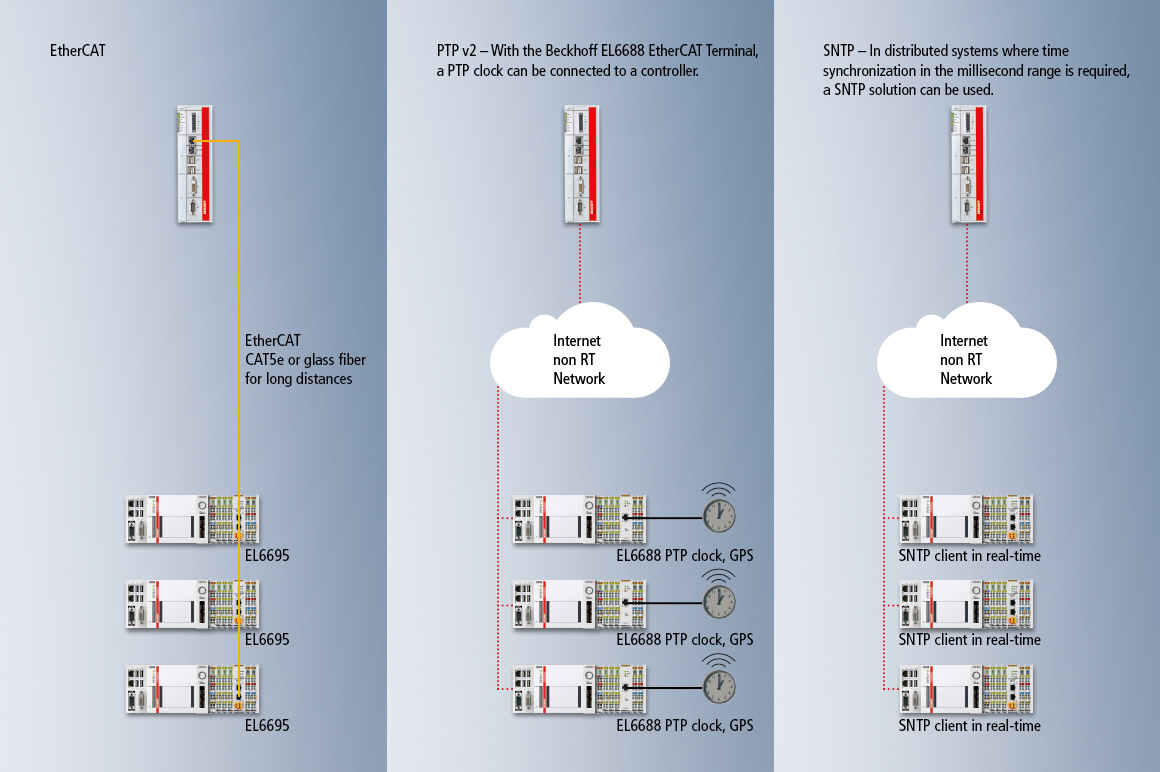

With the help of the TwinSAFE SC technology, it is possible to qualify standard signals for safety tasks in any network or on any fieldbus. For this purpose, corresponding EtherCAT Terminals are available for the acquisition and safe transport of these signals via EtherCAT.

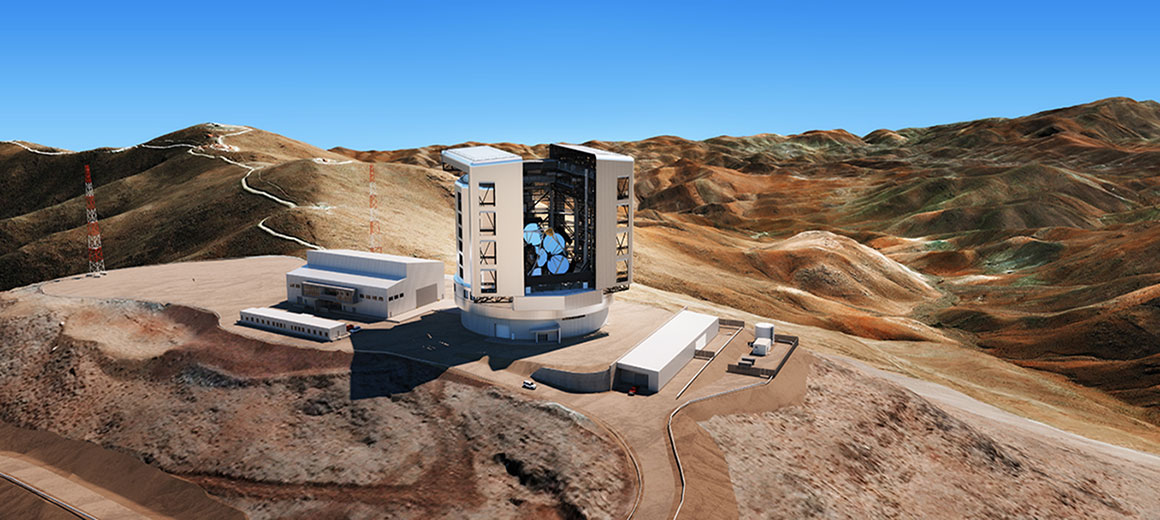

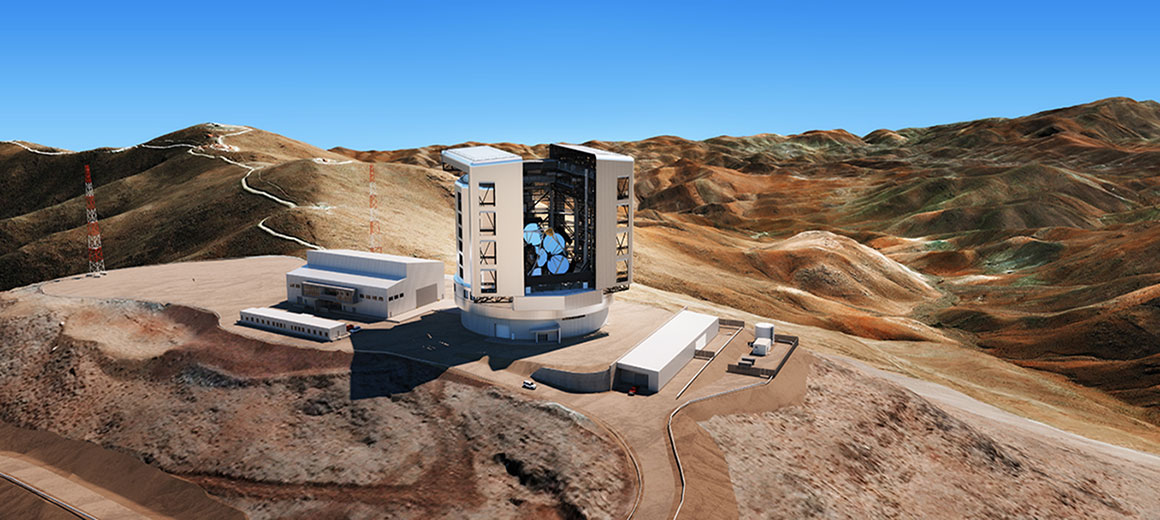

Large networked plants pose major challenges for all parties involved, especially with regard to safety technology. Many networked machines and plant sections with their own safety zones, spread over large areas, hinder the overview and make subsequent extensions and adaptations a herculean task. TwinSAFE offers the option to completely or partially decentralize the safety application as required. Each machine, each plant section or, if necessary, each unit can easily be equipped with its own safety logic. The TwinSAFE logic is part of every safe input or output terminal and also of many drive components. This makes it easy to create autonomous safety areas that can communicate with one another. If necessary from a process point of view, sections can be switched off interference-free during operation, even though they are a part of the safety chain. During the use of the plants and commissioning, individual units and machines can be verified and validated in terms of safety by the respective department.