Products

VUI2000

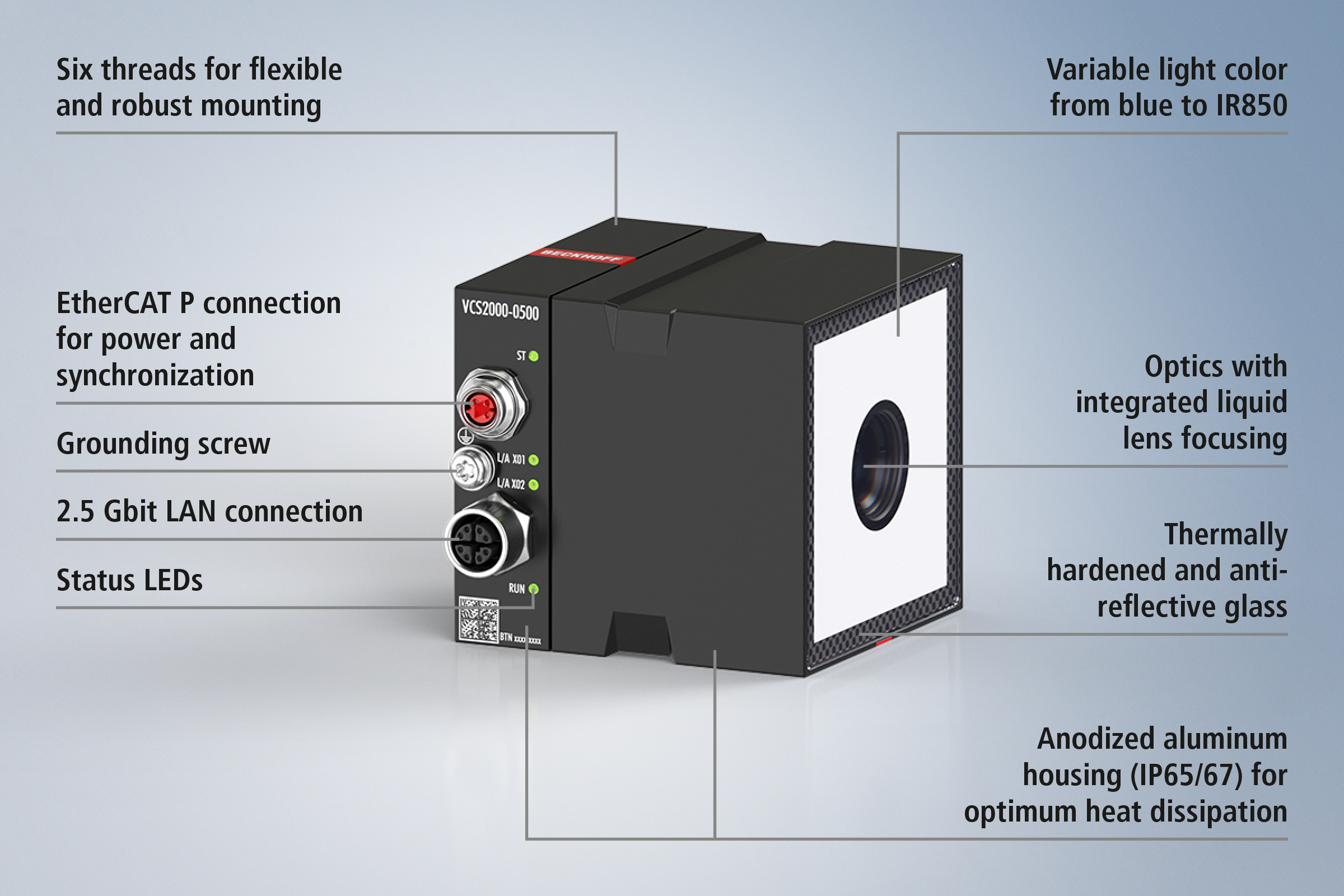

Complete solution: 2.5 Gbit/s camera, multicolor LED illumination, and optics with controllable focus in a single module

Start industrial image processing immediately with the unit

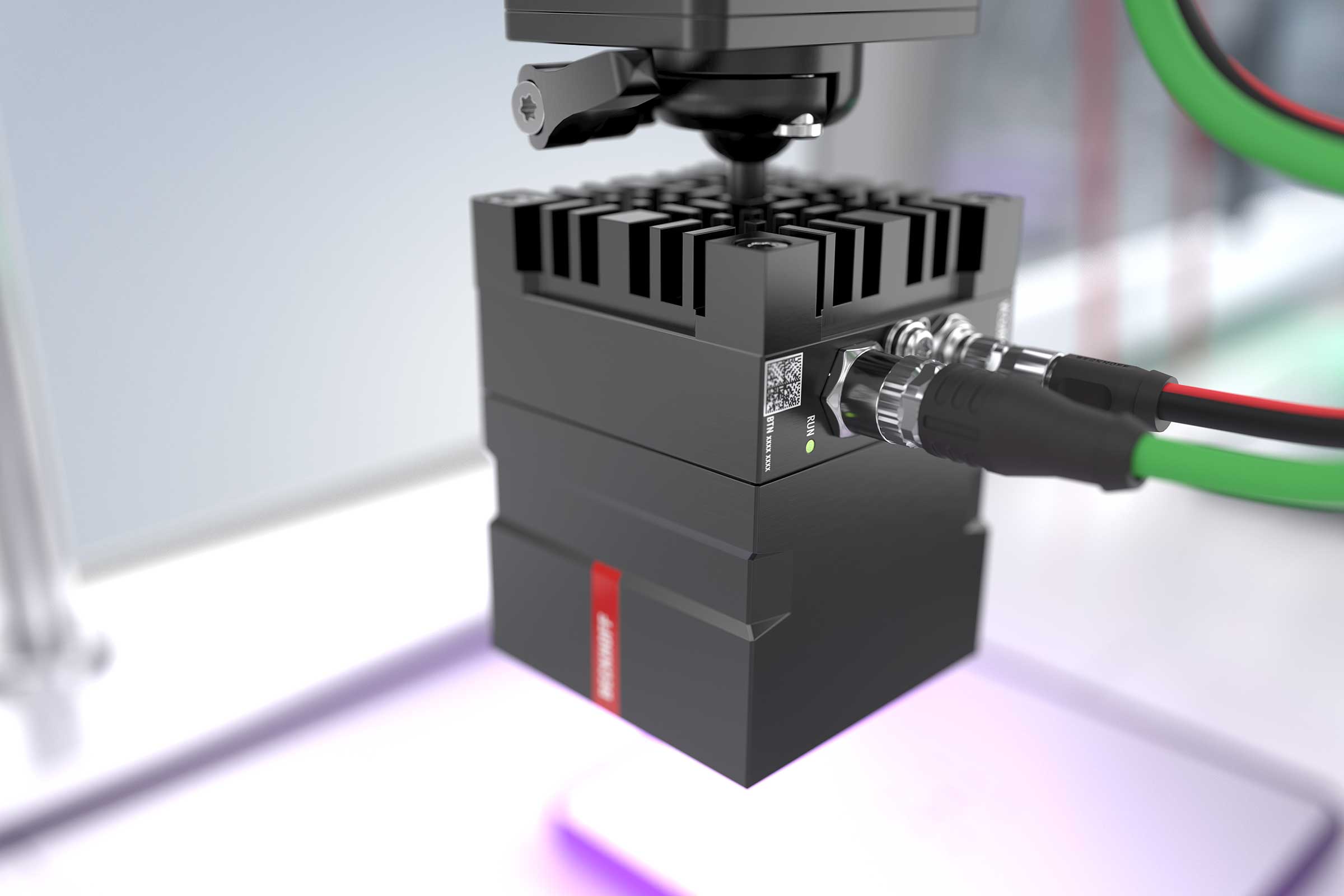

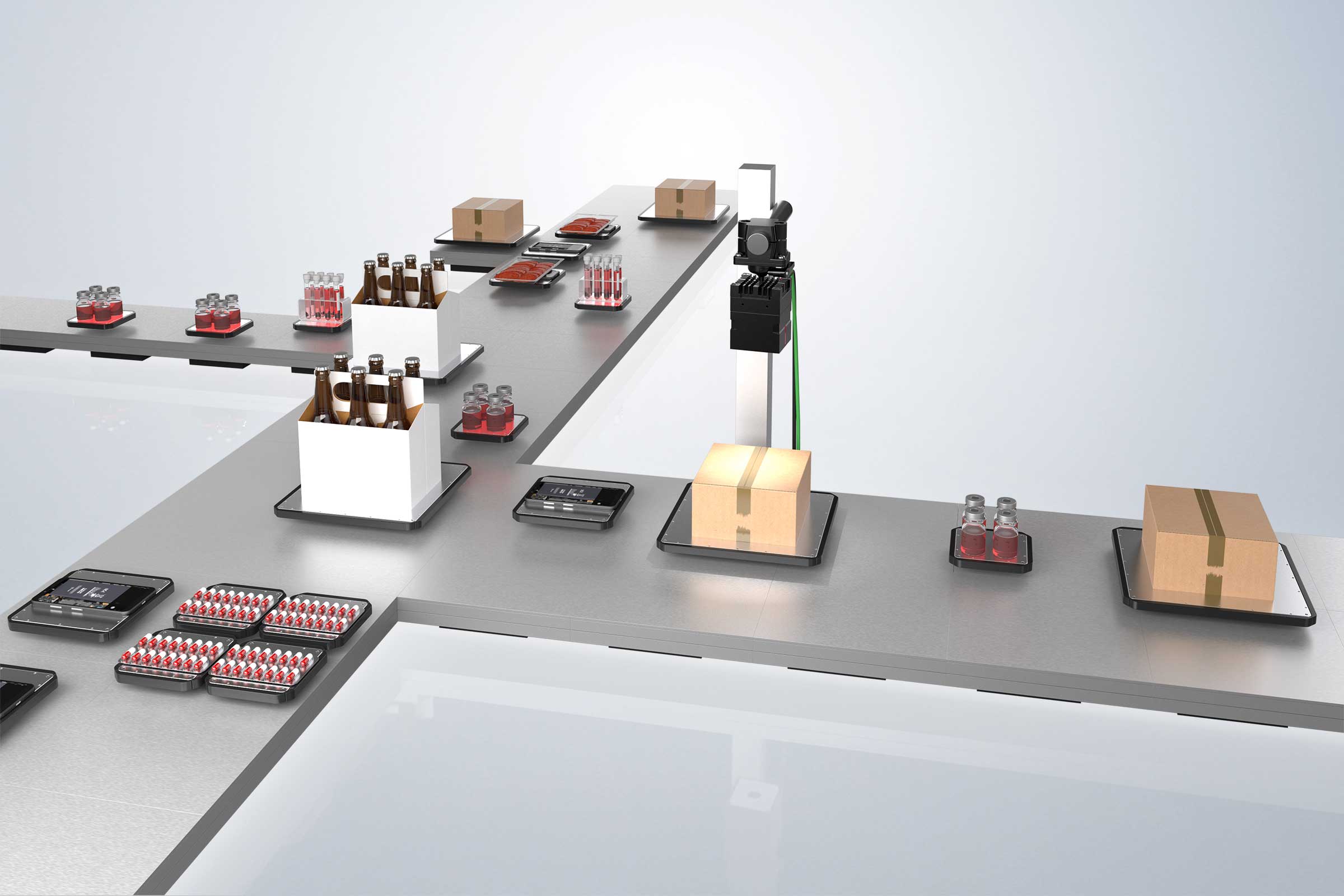

The Vision Unit Illuminated (VUI) is a compact unit comprising a camera, illumination, and focusable optics complete with liquid lens technology. It significantly reduces installation and commissioning labor and, thanks to focus adjustment during runtime, it is particularly well-suited for work with changing component heights, as is common in logistics applications. What’s more, all functional components are encased in elegant IP65/67 anodized aluminum housing.

An all-in-one solution comprising a camera, illumination, and focusable optics

When it comes to image acquisition, the PLC controls all settings for the individual functional components (camera, illumination, lens) during runtime via EtherCAT with high precision and is perfectly synchronized with all processes in the application. In this way, direct adjustments to different working distances, for example, can be made by electronically adjusting the focus position.Along with the intensity and length of the light pulse, the light color and other parameters of the image acquisition camera can also be controlled via EtherCAT. Focusing during runtime is facilitated by a robust liquid lens that can be used in any position. It also offers exceptional shock and vibration resistance in addition to an extremely long service life on account of the high number of cycles.

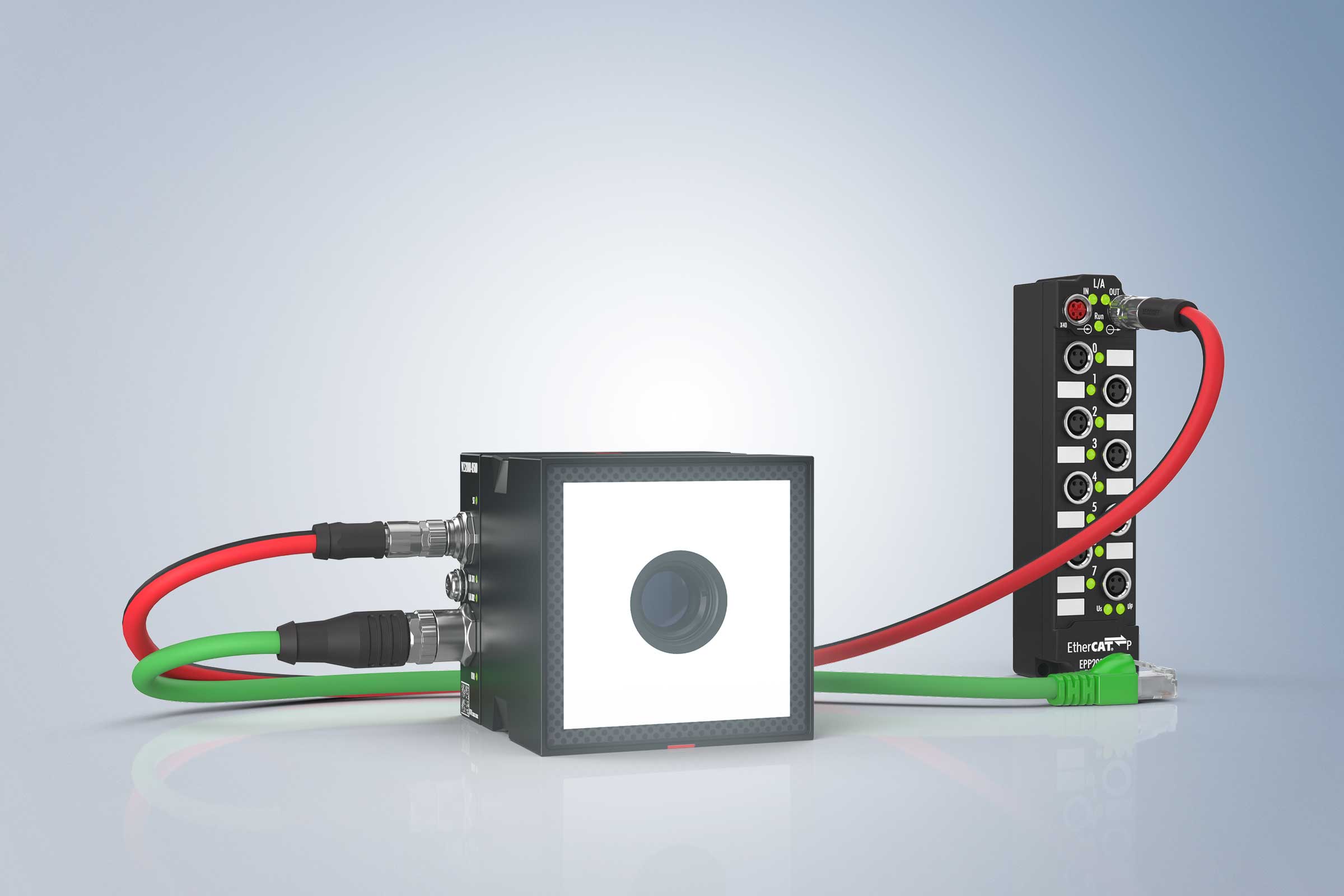

EtherCAT supports highly accurate time synchronization of all devices network-wide

Due to the synchronization capability of the EtherCAT devices via distributed clocks, pulse operation is easy to implement, since no external trigger loop is necessary for the camera or illumination. The integration of EtherCAT into TwinCAT means the pulse times of the illumination can be synchronized to all other EtherCAT devices in the network without additional hardware and software interfaces. The devices are equipped to support the high-precision time synchronization of all inputs and outputs, typically with time uncertainties of well below 1 μs. This applies both relatively – in relation to the devices in a network – and absolutely to a higher-level global reference time. Highly accurate time synchronization is fundamental for efficient flash operation and for sophisticated scenarios with multiple units, illumination sources, and cameras. It allows complete synchronization of the automation elements with the vision elements, which makes the system or machine extremely homogeneous and eliminates system boundaries.

Optimal image results through synchronization with distributed clocks

- from the camera shutter

- from the illumination shutter

- from the pulse intensity

- from the spectral adjustment of the light

Further advantages

- storage of image data with reliably traceable timestamps

- synchronization of the vision system with all other automation elements

- shorter cycle times and improved product quality

- transparent communication and complete parameterization on a fieldbus basis

Advantages at a glance

Start work immediately with the unit

- unit comprising camera, illumination, and focusable optics

- compact ring light

- focusable fixed focal length lens with liquid lens

- resolutions from 1.6 MP to 5 MP

- color or monochrome

- encased in elegant IP65/67 anodized aluminum housing

- laterally oriented connectors for straightforward mounting

- directly integrated into the PC-based control technology

Full synchronization with all EtherCAT-based machine processes via distributed clocks

- straightforward unit connection with One Cable Technology for power supply and synchronization

- real-time applications for optimized manufacturing processes

- image acquisition synchronized with Beckhoff illumination and all other processes with outstanding precision

- no external trigger loops necessary

- rapid reactions through the integration of vision into the control system

- easy integration into the infrastructure via EtherCAT P

- storage of image data with reliably traceable timestamps

- reduced wiring effort along with simplified commissioning and straightforward diagnostics

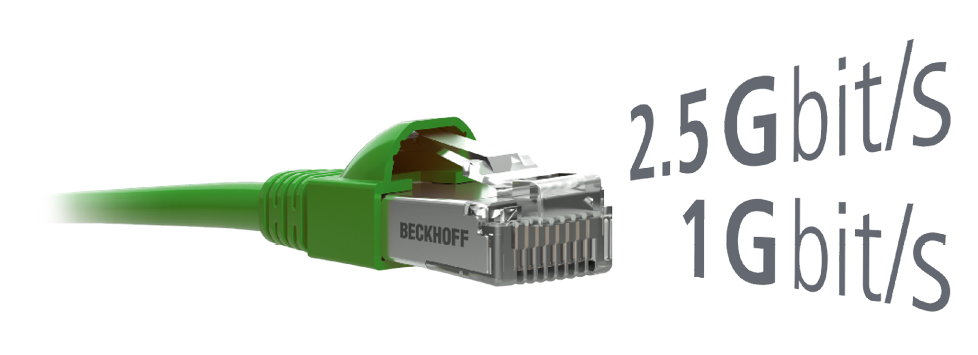

Rapid image data transfers at 2.5 Gbit/s fully exploit the performance potential of the unit

- increased frame refresh rate

- cost-effective use of the high transmission rate of 2.5 Gbit/s

- faster response times thanks to industrial LAN technology for any cable length

- optimally matched to the powerful industrial PCs

- efficient interaction of all system components for maximum productivity

Ability to adjust the image contrast during runtime for maximum flexibility

Multicolor LED illumination for each object can be individually adjusted as follows

- three selectable channels (blue, green, orange) in the visible spectral range serve to optimize image contrast

- a mixture of these three visible channels produces white light

- IR850 offers an excellent light source to suppress visible features such as multiple print colors

Generation of the light colors in terms of

- best possible temperature stability for complete coverage of the visible spectrum via blue LED semiconductors

- green and red-orange spectral ranges are converted via phosphors for this purpose

- increased efficiency at high temperatures: high light output available in applications with high ambient temperatures

Integrated robust liquid lens

- ideal for applications with variable focus in image processing due to

- exceptional shock and vibration resistance

- very long service life due to high number of cycles

- position-invariant use

- focus adjustment during runtime, especially for variable component heights, such as those commonly found in logistics applications

- seamless integration into PC-based control technology for remotely adjustable focus settings

Suitable for use even in demanding industrial environments

Long-term availability of the developed types of housing and technology is assured.

Advantages of the robust housing

- attractive anodized aluminum housing that offers IP65/67 protection against water and dust

- highly visible status LEDs visualize operating states

- thermally hardened and anti-reflective glass for high mechanical and chemical resistance while cleaning and handling

- anti-shatter film for glass surfaces available on request

Advantages of the wide temperature spectrum

- greater flexibility which enables new applications

- extended application possibilities even in demanding environments

- simplified warehousing and purchasing

- reduced costs

Advantages of in-house development and production

- assured long-term availability of the developed types of housing and technology

- best possible vision solution in terms of technology and quality with a consistently high level of functionality

- robust product design of the components

- long-term partnership with leading technology and component suppliers