Module Type Package (MTP)

Hoofdkantoor België

Beckhoff Automation BV

Module Type Package (MTP)

With modular automation, process technology plants can be flexibly implemented and adapted with little effort. Rigid automation systems that have been operated unchanged for years are increasingly becoming a thing of the past, with individuality and flexibility asserting themselves as the future of the process industry. The Module Type Package (MTP) is a concept that allows process technology plants to leverage maximum potential across the board, from the planning phase through to operation. This makes MTP a crucial component in the development of future modular automation solutions.

Advantages of Module Type Package (MTP)

Advantages and features of TwinCAT MTP

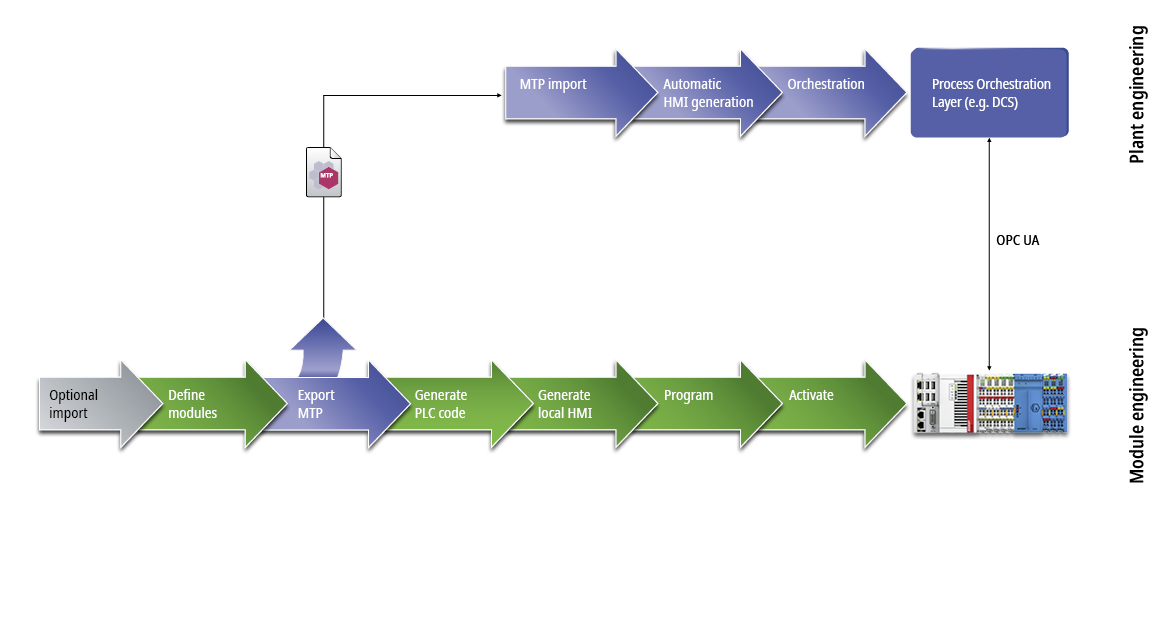

The Module Type Package (MTP) concept is integrated into TwinCAT via TwinCAT MTP Runtime and TwinCAT MTP Engineering. TwinCAT Engineering includes a project management system that TwinCAT MTP Engineering is integrated into as its own project type. The project type enables the generic definition of a module, and the MTP file can be generated based on this before programming. Existing information can be processed via an open API, an MTP import, or a DEXPI import. In addition, the information can be used for automated PLC and HMI generation.

Subsequent changes in MTP project management are integrated by means of automatic project synchronization. Only the actual process logic of the functionalities being offered needs to be programmed in the prepared state machine.

Finally, the project can be activated, which automatically makes the variables of the defined interfaces available to the POL via OPC UA.

The following interactive graphic explains the process from the development of the module with TwinCAT MTP to its integration into the plant in individual steps. Then, application scenarios for TwinCAT MTP at the various levels of a process technology system are illustrated with short videos.

MTP makes process technology systems modular and cuts down on both the initial engineering work and the work that goes into reconfiguring a system.

This video shows you how the MTP concept works at plant level. It illustrates how the MTP concept can be applied in both greenfield and brownfield scenarios.

This video shows how the MTP concept works at module level. A distinction can also be made between greenfield and brownfield applications at module level.

Specifically, this video shows how modularity can be implemented within the module using functional units in the greenfield. These functional units are designed dynamically so that they can be integrated flexibly, allowing the module to be customized for the current application.

This video shows how the MTP concept works at module level. A distinction can also be made between greenfield and brownfield applications at module level.

Specifically, this video shows how brownfield modules based on existing skids can be created with the MTP gateway. If several modules need to be implemented on one control unit, the MTP hub is a cost-effective solution.

In this use case, Ajinomoto Omnichem (an Ajinomoto Group company) and Beckhoff successfully demonstrated how the Module Type Package concept can be used to automate an industrial plant.

A special feature of the plant shown is the use of the MTP hub. In this application, all modules of the plant were implemented on a central Beckhoff control system. The PC-based control technology makes it possible to implement the modules in independent PLC programs and make them available to the POL separately. Through this architecture, the plant structure can be changed without having to adapt the control system – it automatically recognizes which modules are currently connected. The plug-and-produce behavior of the MTP concept enables simple reconfiguration in the POL, which has reduced the changeover time considerably.

An MTP (Module Type Package) is a communication interface between a higher-level control system (e.g. process control system) and a modular plant. The MTP describes the interface of visualization, provided services and other features of a module, so that a simple orchestration of the modules to form a complete plant can be done easily and quickly in the higher-level control system.

An MTP (Module Type Package) is a communication interface between a higher-level control system (e.g. process control system) and a modular plant. The MTP describes the interface of visualization, provided services and other features of a module, so that a simple orchestration of the modules to form a complete plant can be done easily and quickly in the higher-level control system.

OPC UA is a platform-independent, service-oriented communication architecture for reliable, secure and multisupplier data transport from the production level to the production planning and ERP system or to the cloud.

The TwinCAT Controller Toolbox covers all essential blocks for control applications. All blocks have the same appearance and almost the same properties. Simple parameterization via a structure and the same error handling for all blocks support the application.

The scalable C60xx series combines maximum computing power in what is currently the most compact format with a wide range of options for installation in the control cabinet.

The DIN-rail-mountable, fanless Embedded PCs from the CX5100 series are equipped with Intel Atom® multi-core processors.

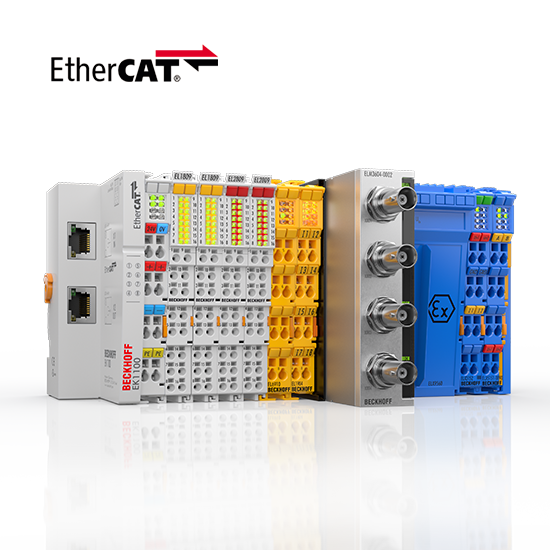

The EtherCAT Terminal system provides a comprehensive range of products for all signals in the world of automation.

As the front end of a machine, the Beckhoff Control Panels are its visual and functional business card and allow a wide range of customer-specific adaptations.