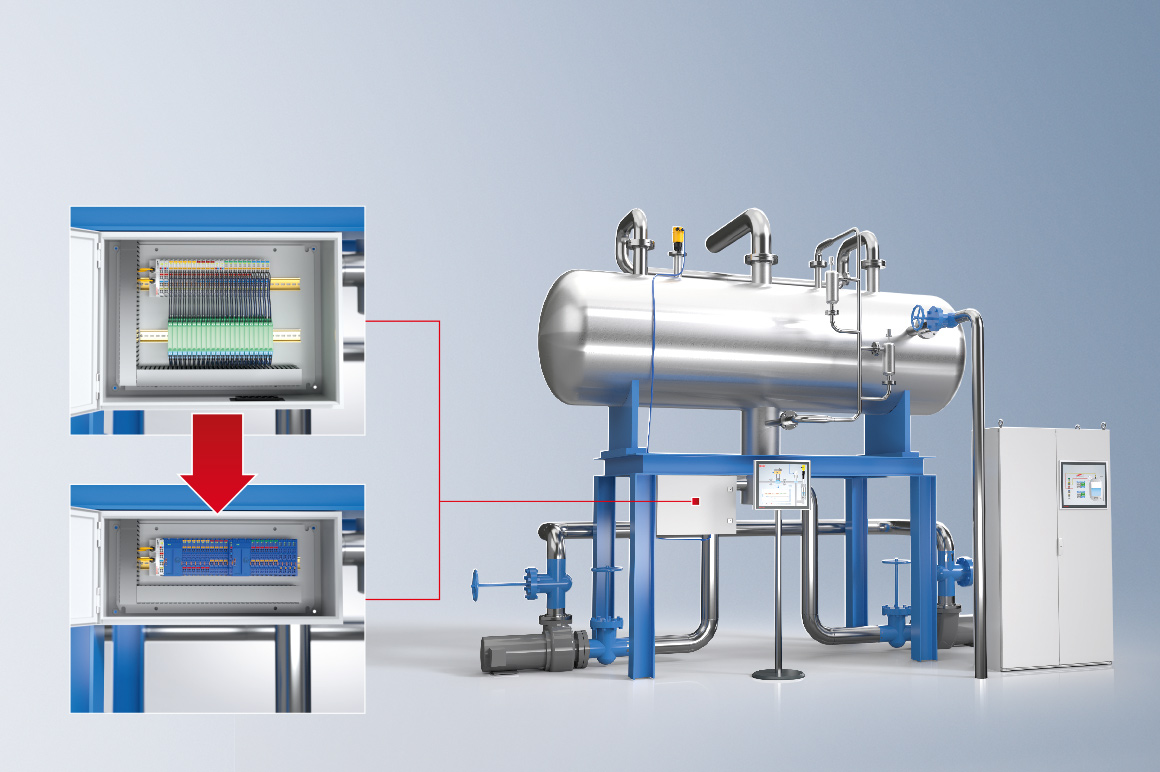

The control system for process automation

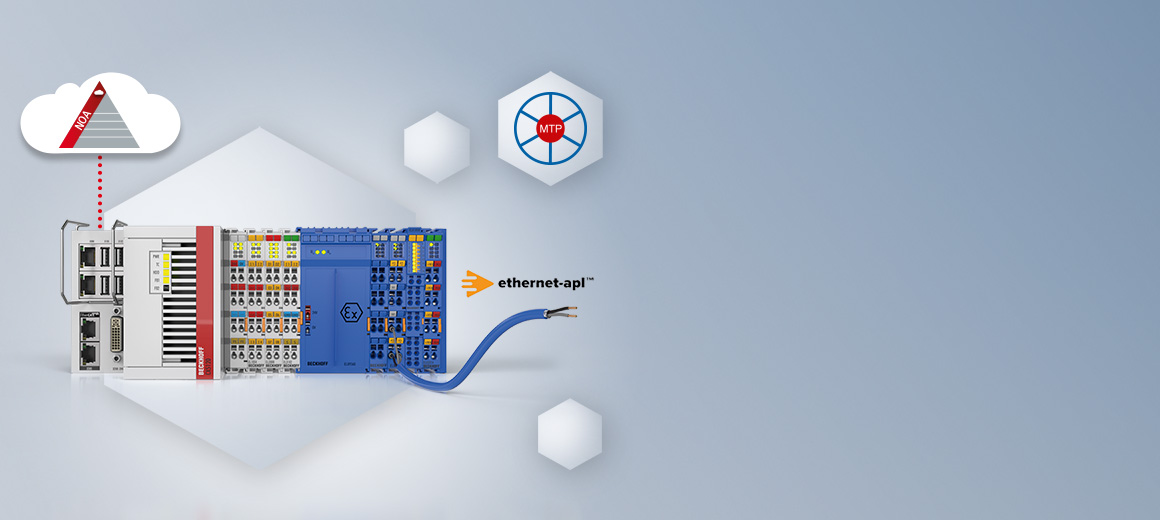

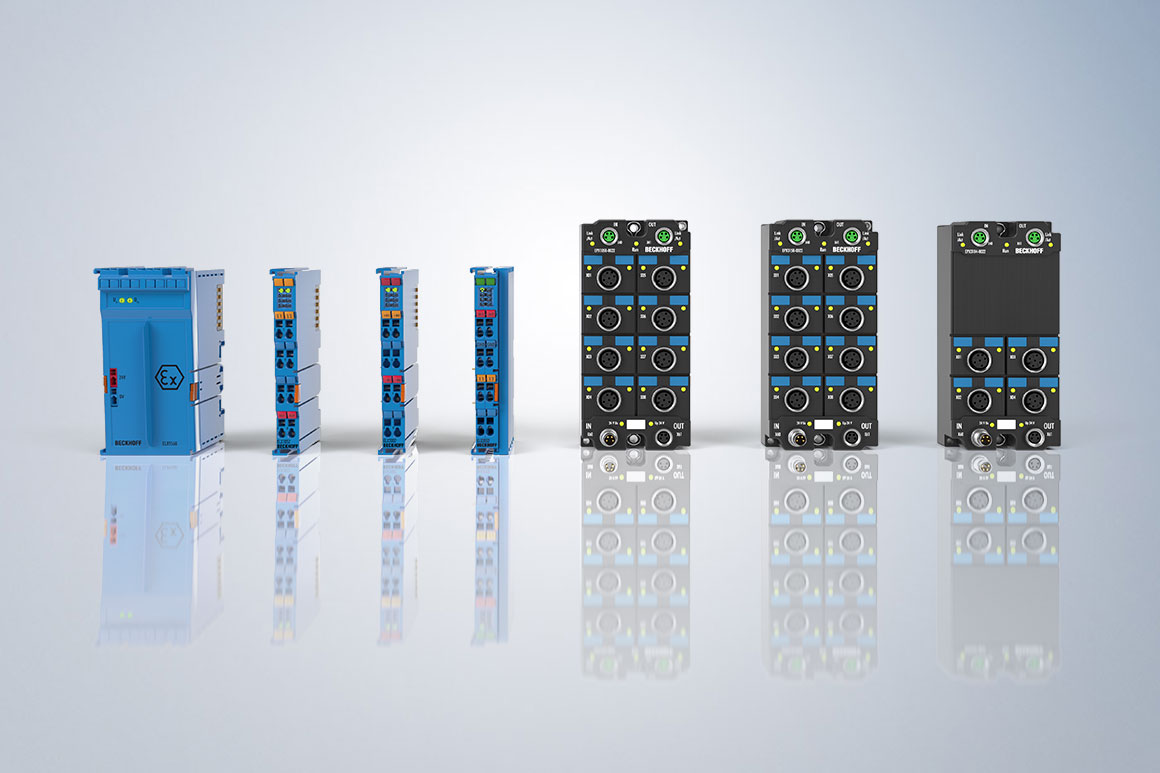

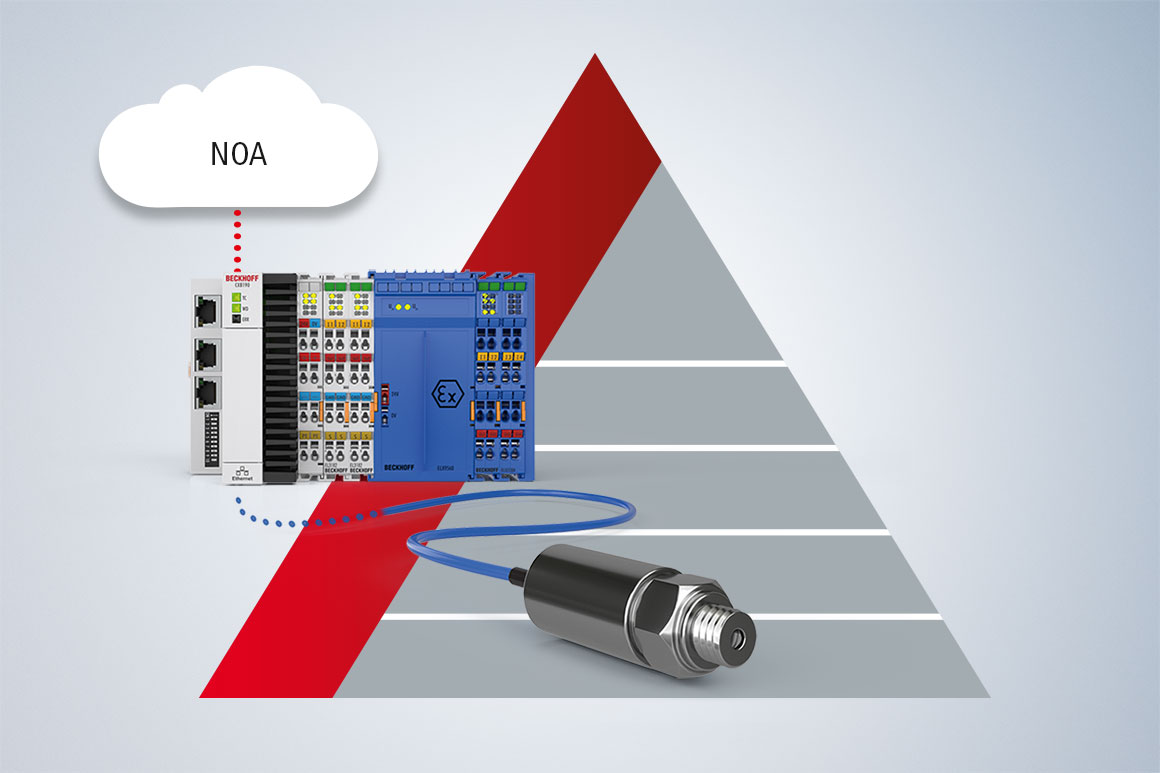

Beckhoff calls on a comprehensive modular range of components and deep-rooted, cross-sector expertise to create open automation systems using PC-based control technology. All control functions, such as PLC, visualization, cloud connection, safety technology, and measurement technology, are integrated on a universal platform.

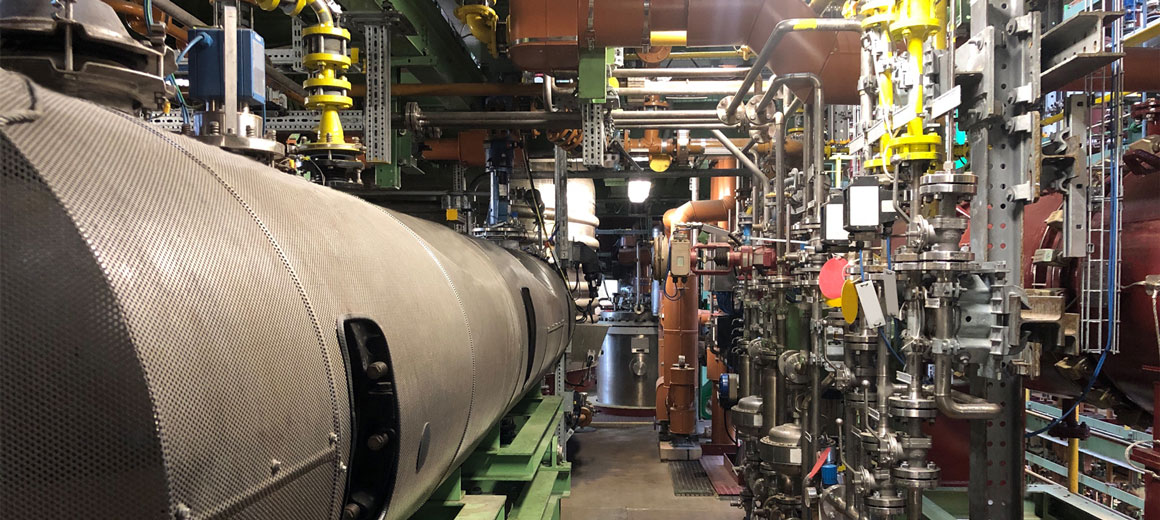

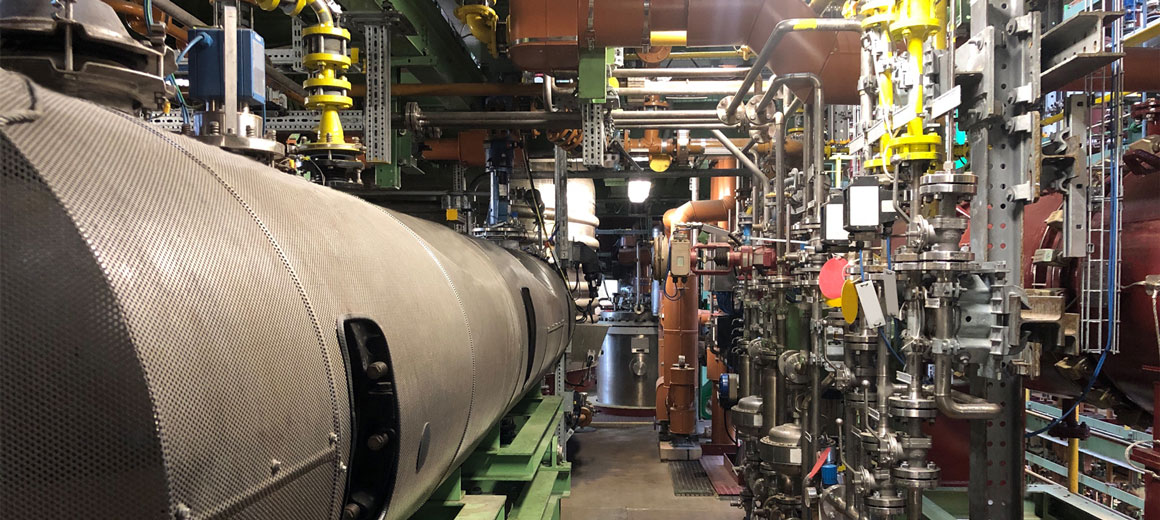

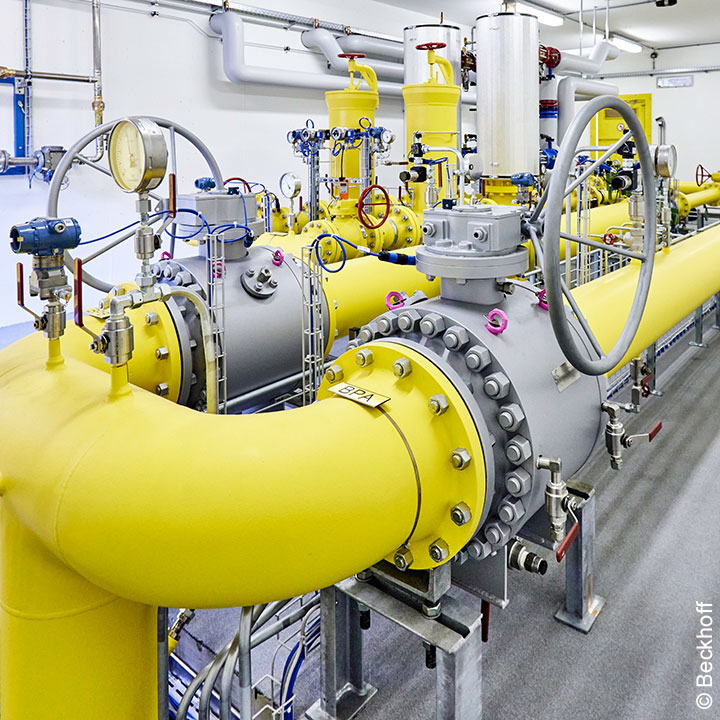

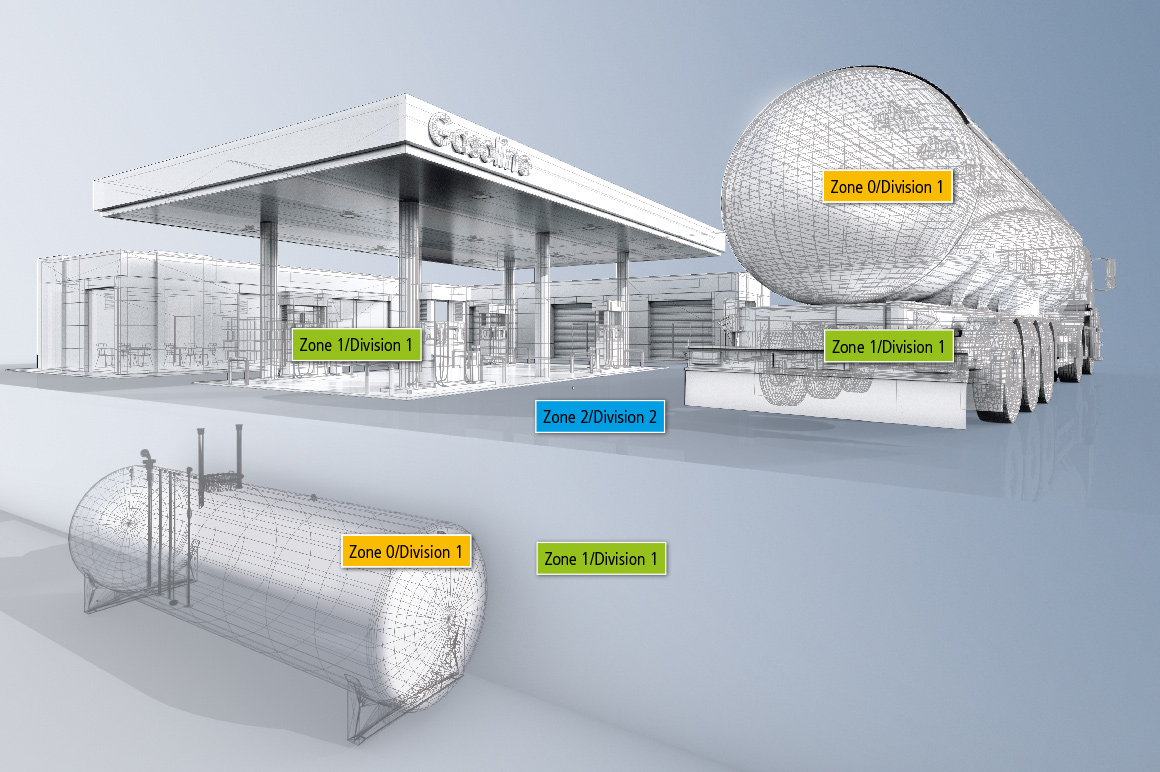

System-integrated solutions from Beckhoff offer an efficient alternative to traditional suppliers and are suitable for use in numerous markets, including oil and gas production, chemicals and petrochemicals, the hydrogen industry, metal processing, or the water and energy industries.

PC-based control for the process industry:

- universal platform for the automation of all processes and plants

- integration of all control functions in one system

- high interoperability thanks to open interfaces in hardware and software

- control and cable redundancy for increased plant availability

- established worldwide across all industries