Beckhoff supports the umati initiative

for standardized communication with machine tools

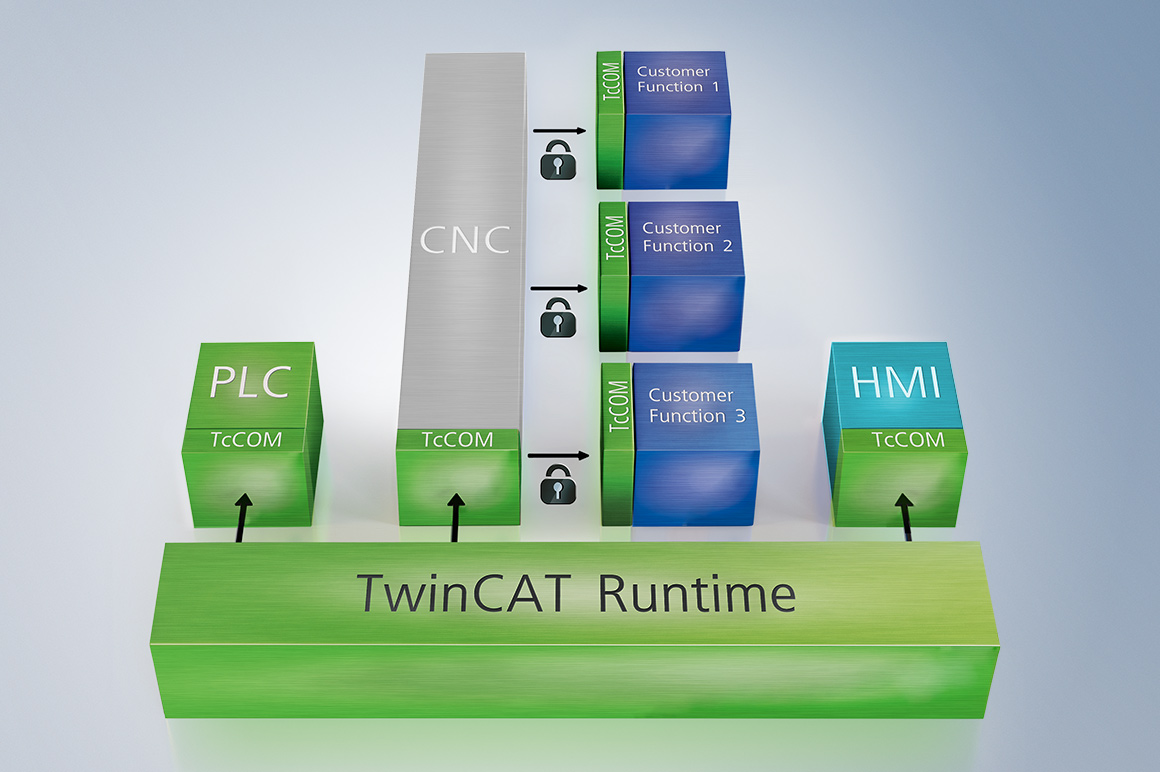

TwinCAT 3 CNC

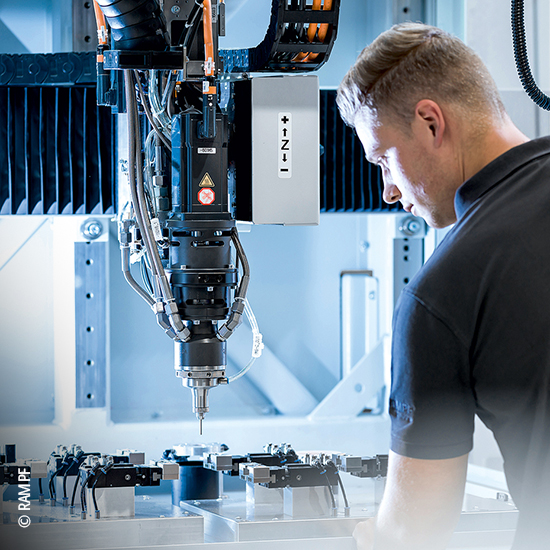

Effortless access to high-performance CNC solutions for EDM and additive manufacturing

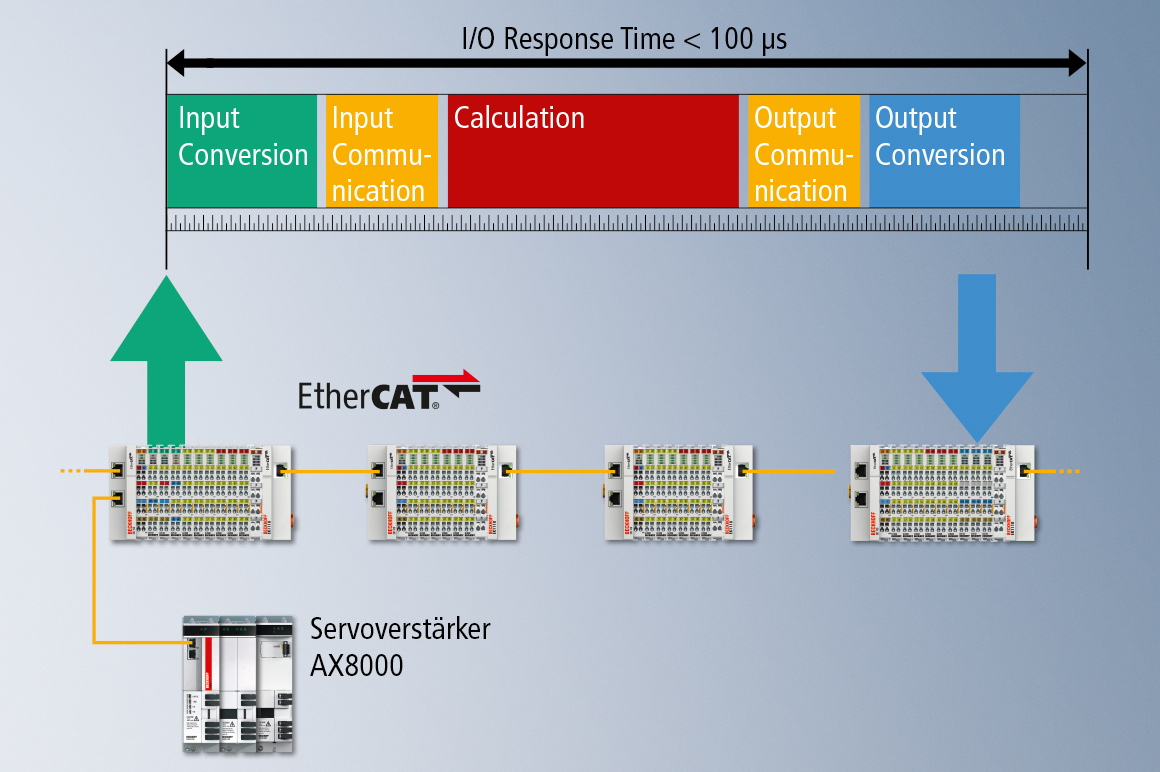

High speed and precision perfectly aligned in software-controlled solution

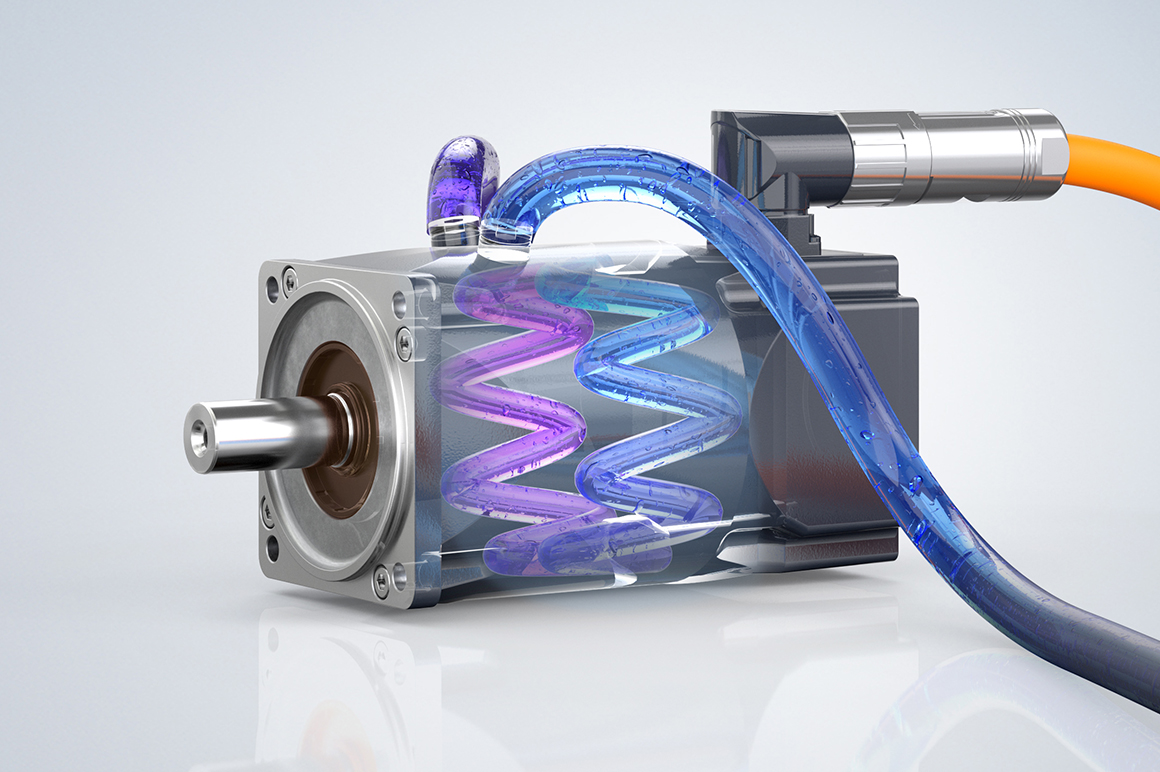

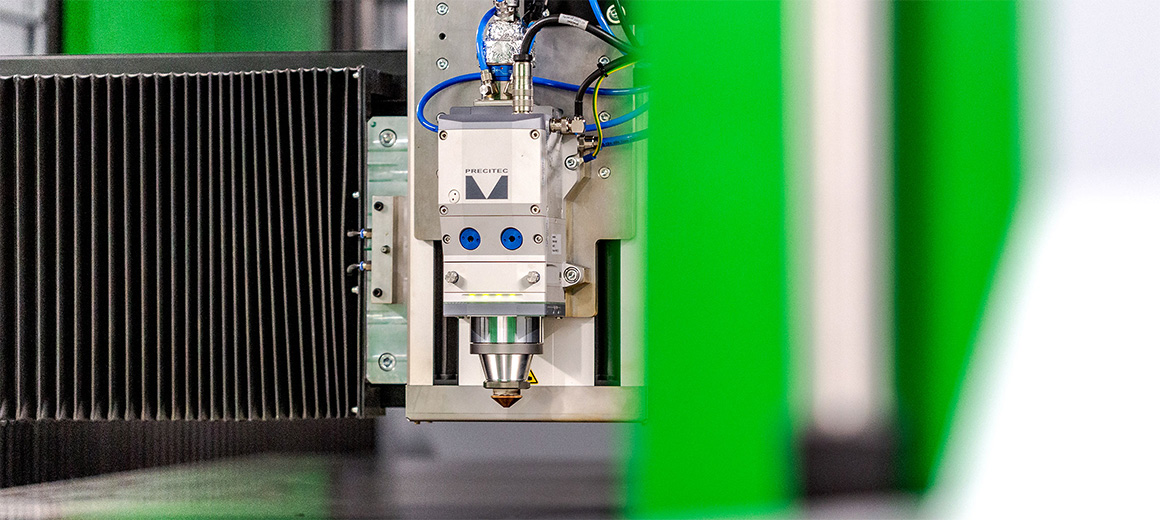

Laser cladding with TwinCAT CNC

Beckhoff supports the umati initiative

for standardized communication with machine tools

TwinCAT 3 CNC

Effortless access to high-performance CNC solutions for EDM and additive manufacturing

High speed and precision perfectly aligned in software-controlled solution

Laser cladding with TwinCAT CNC