TwinCAT Motion Control: perfectly suited for hydraulic and electric drive technology

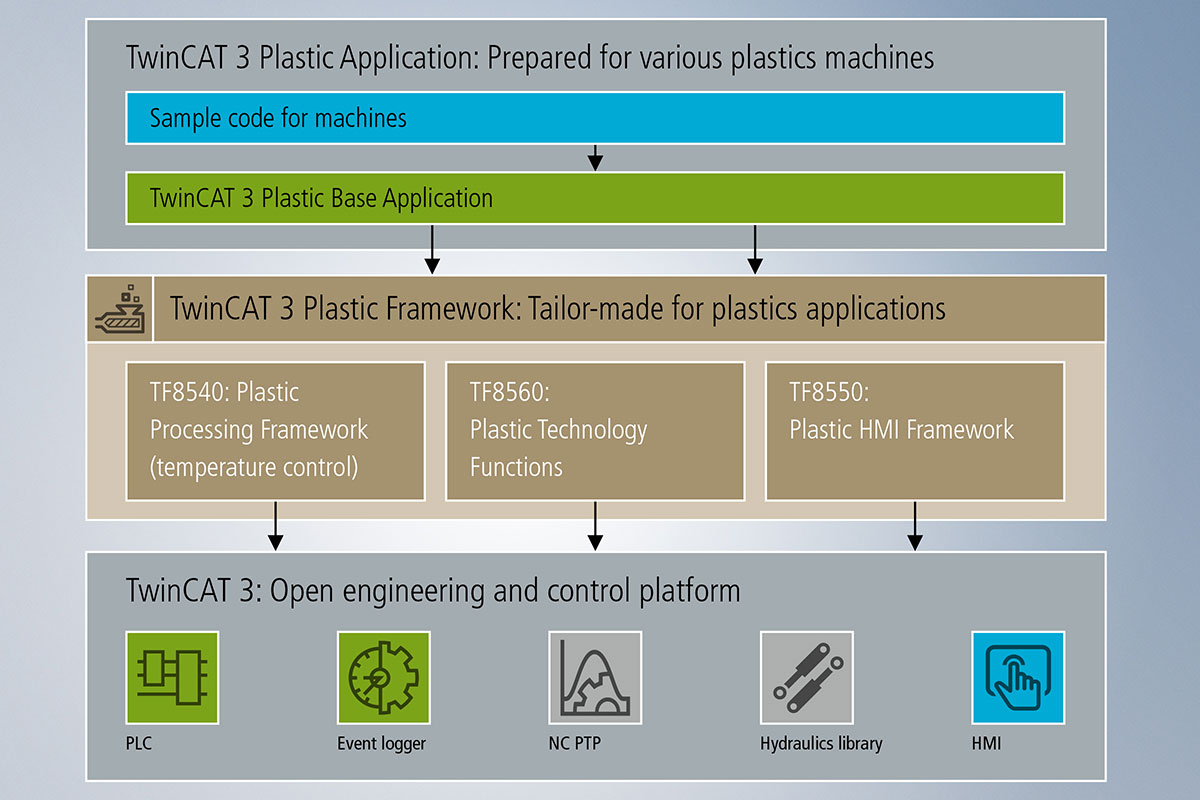

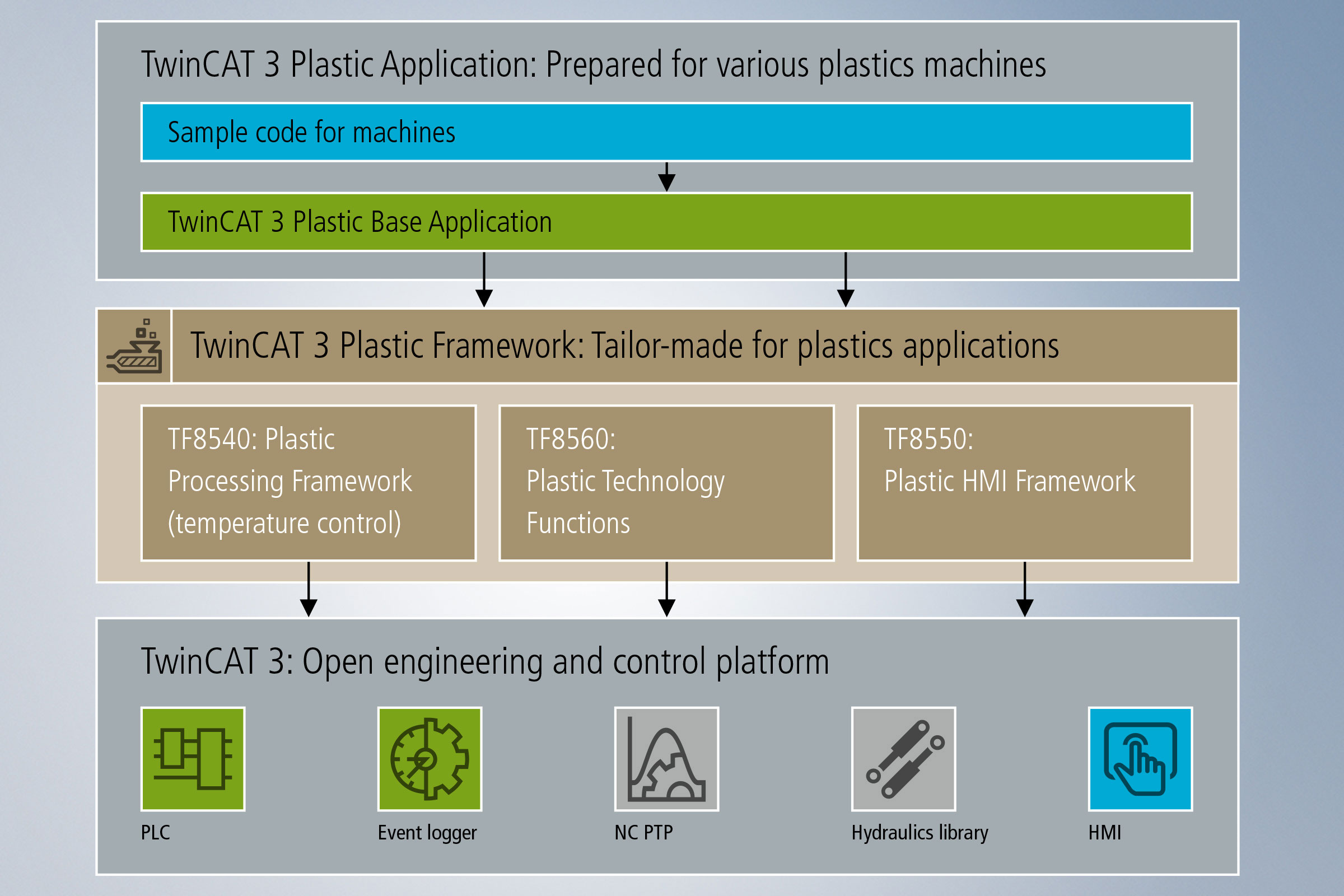

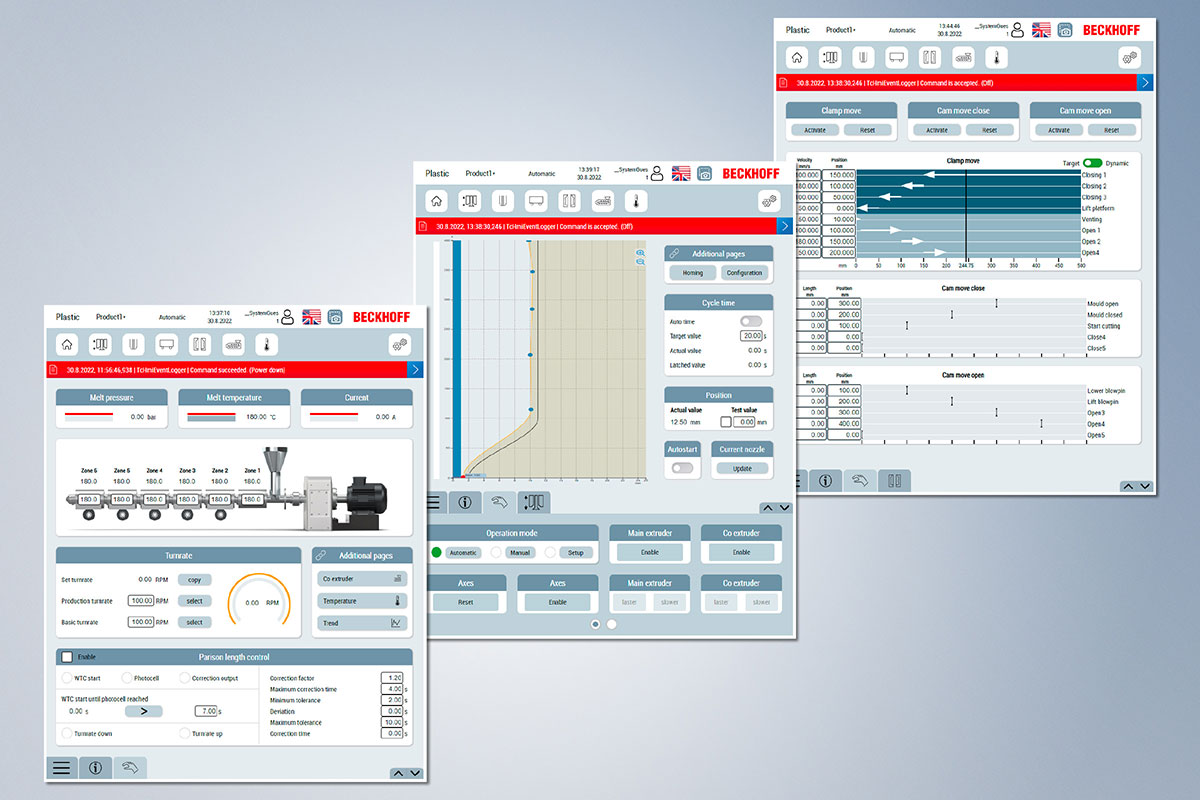

Hydraulic, electric or hybrid drive technology is used in injection molding and blow molding machines. With the TwinCAT technology modules for motion control, the machine manufacturer gains access to the long-standing Beckhoff know-how in all areas of motion control and can develop the different drive types in an engineering environment.

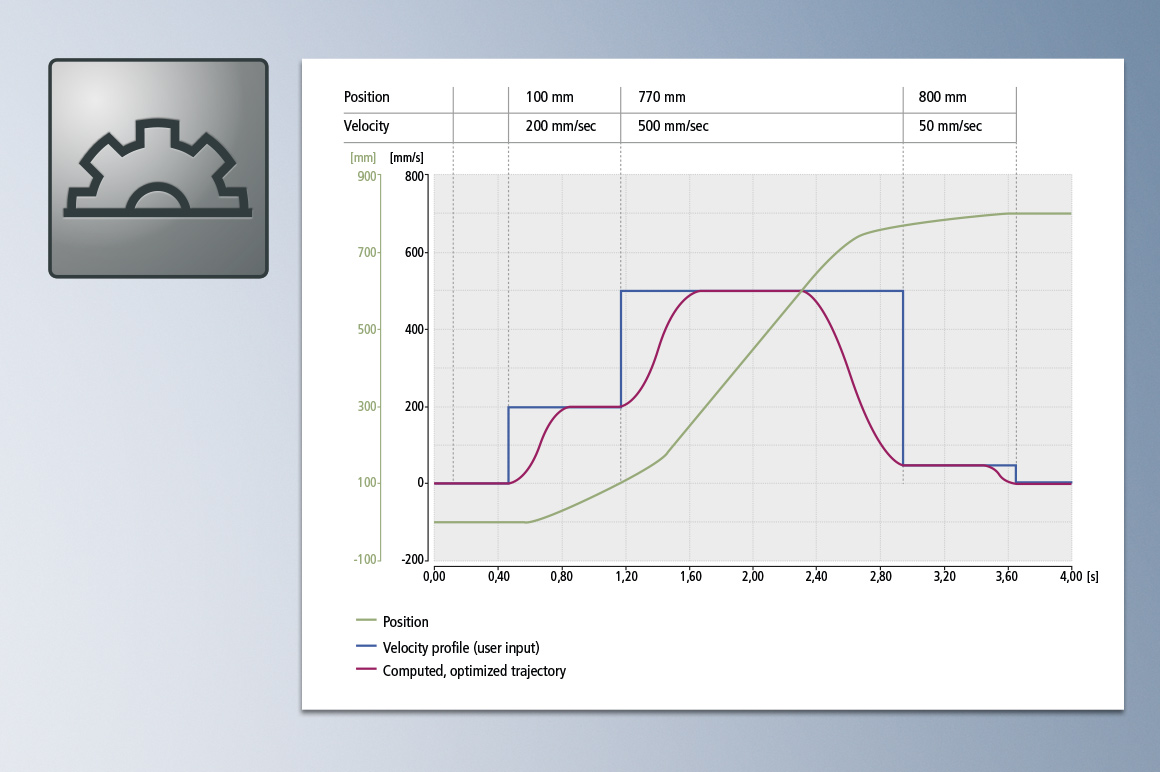

Electric drive concepts for plastics machines can be realized with TwinCAT NC. In combination with the TwinCAT Application Plastic Components, the NC is ideally suited for alternating control concepts, such as position and pressure control. Setpoint generators with jerk limitation reduce mechanical excitation and increase the service life and accuracy of the machine.

Plastics machines often still use hydraulic drive concepts. The TwinCAT Hydraulic Positioning software library provides all the necessary functions for this. Various hydraulic concepts are supported, such as valve or pump-controlled axes or servo pumps. Any hydraulic axes can be optimally operated through adapted setpoint generators, automatic characteristic curve identification, segmented movements and freely programmable switching between force, pressure and position control.

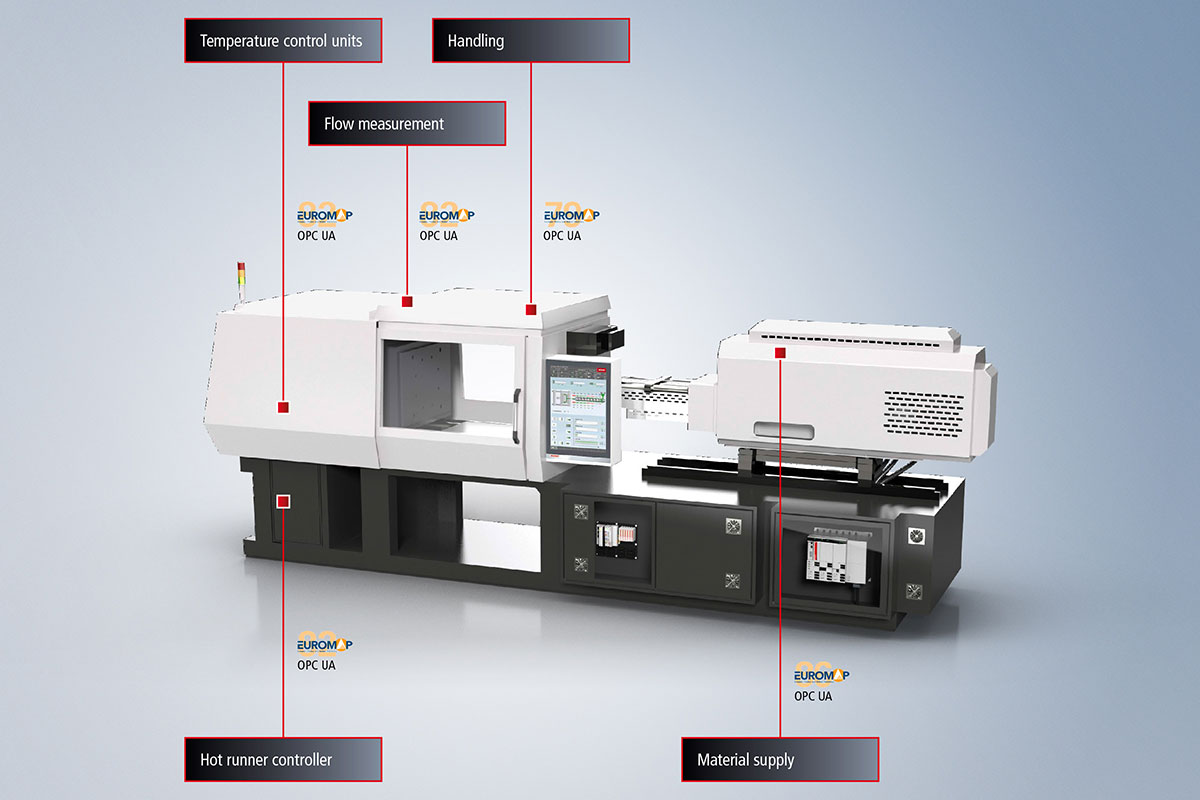

A combination of electric and hydraulic drive technology as used in hybrid machines is developed in an identical Motion Control environment with TwinCAT. As an industry-specific extension of the Beckhoff TwinCAT software platform, the Plastic Application Components support the widely used Euromap interfaces between injection molding machine and robot, either as Euromap 67 or in the future as Euromap 79 (OPC 40079).