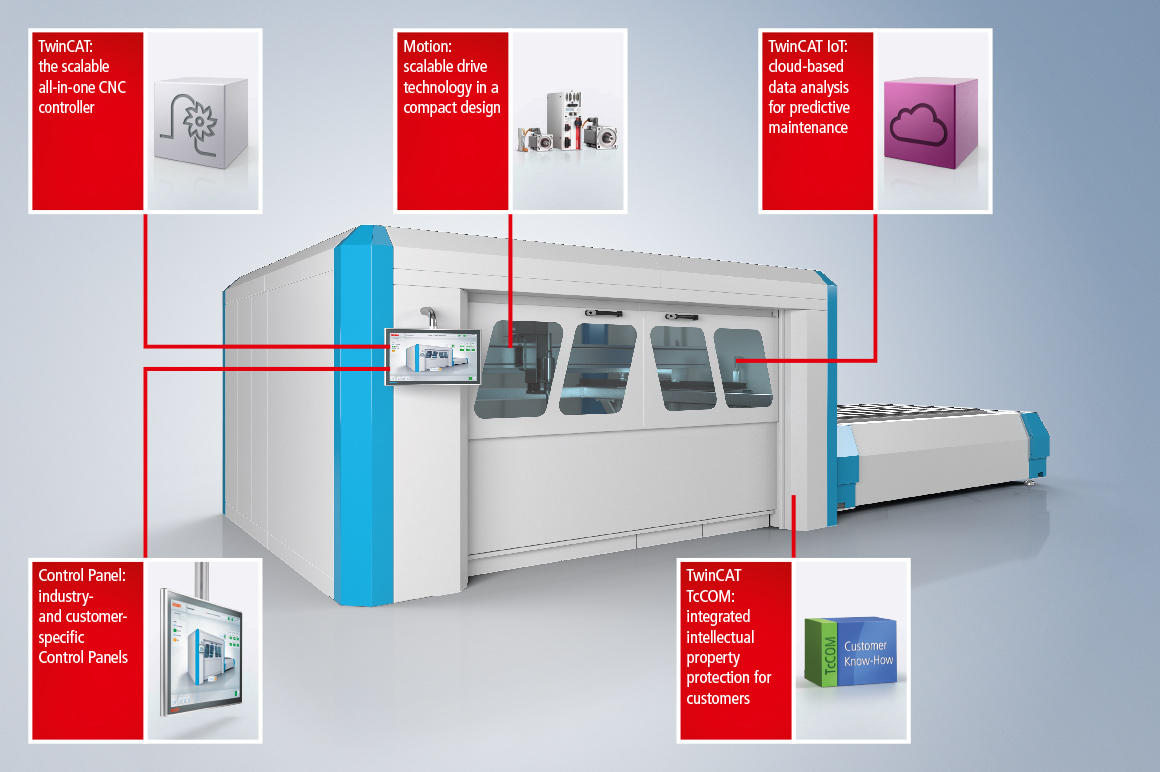

Beckhoff CNC controllers are used in oxy-fuel, plasma, laser and water jet processing for cutting and welding sheet metal. Two parameters are crucial for competitiveness here: the control speed and the scope of the CNC functions. The Beckhoff solution is superior in both respects.The Beckhoff solution is superior in both respects: Firstly, through high-performance control via EtherCAT, which enables cycle times of less than one millisecond and thus supports particularly fast cutting and welding applications. Secondly, the TwinCAT CNC automation software seamlessly covers all specific CNC requirements with special software blocks and integrates them into the control platform.

PC-based control optimizes cutting and welding machines

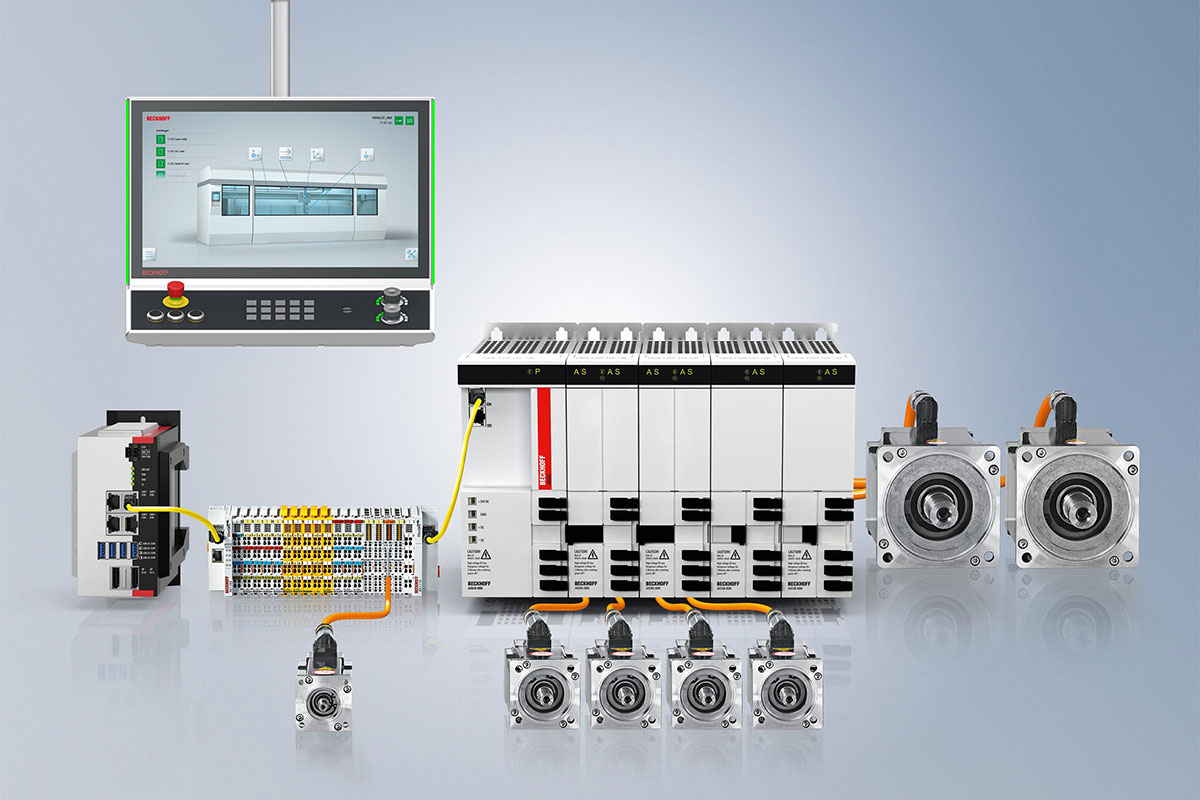

With its entire product portfolio, from Industrial PCs to I/Os to drives, Beckhoff relies on compact designs and thus supports the machine manufacturer in the realization of a lean machine design. From the ultra-compact Industrial PCs of the C60xx series, which are characterized not only by their small dimensions but also by high processor performance, to the I/O peripheral components from the IP67 range with One Cable Automation via EtherCAT P, to the drive technology without a control cabinet, the AMP8000 modules and the matching servomotors with integrated power stage. All in all, a considerable amount of mounting space is saved in the control cabinet, or the latter can even be omitted completely, resulting in a significant reduction in the footprint of cutting and welding systems.

Application reports and brochures

- 20.03.2025 | Application report

Closed profile rings – the advantage of the fourth bending roller

Moser-Baer AG, SwitzerlandMoser-Baer AG in Switzerland is streamlining the production process for its world-famous railroad clocks with a new type of profile bending machine: With four bending rollers instead of the usual three, the Mobamatic MPB23 profile bending machine, with the mechanical platform developed and built by Moser-Baer, can bend a wide variety of profiles without straight end pieces. The automation specialist Pneutronic AG implemented the complete drive and control technology. PC-based control and the AX8000 multi-axis servo system with TwinSAFE ensure a compact design, precision, and safe operation without safety guards and laser scanners.

- 02.09.2024 | Application report

Scalable for the future with fully integrated, open control technology

Cincinnati Incorporated, United StatesCincinnati Incorporated (CI) has been building sheet metal processing equipment for 125 years and continues to support its durable machines for decades. The company is able to do this because it develops everything in-house, from the hardware to the software. However, the further development of proprietary control technology became too costly and challenging to support. Since the switch to PC-based control, the only limits to development have been physical, according to the engineers at CI.

- 06.11.2023 | Application report

High die casting quality through optimum control of vacuum generation

AJYa Vacuum Technology, ChinaIn die casting, vacuum generation in the shot chamber and mold cavity helps to avoid air and gas inclusions in the castings, as these would impair the stability of the finished parts. For this purpose, AJYa Vacuum Technology from China developed a complex but particularly effective multi-stage solution. A suitable control platform was implemented in cooperation with the automation partner Beckhoff.

- 11.10.2022 | Brochure

High performance built in: PC-based control for sheet metal working

As a specialist in PC-based control technology, Beckhoff provides proven, high-performance automation solutions for sheet metal working.

- 15.09.2021 | Application report

PC control guides precise shaping of the heaviest steel plates

Haeusler, SwitzerlandHaeusler AG, based in Duggingen, Switzerland, is a leading specialist in large-scale facilities for forming metal plates. At the end of 2020, a giant 1,245-ton straightening machine was delivered to one of the largest shipyards in China. The company explains that this plant, the largest of its kind in the world, is used in the production of oil tanker hulls. In this context, PC-based control technology from Beckhoff ensures that the enormous forces for precisely forming steel parts are guided in the right direction.