Products

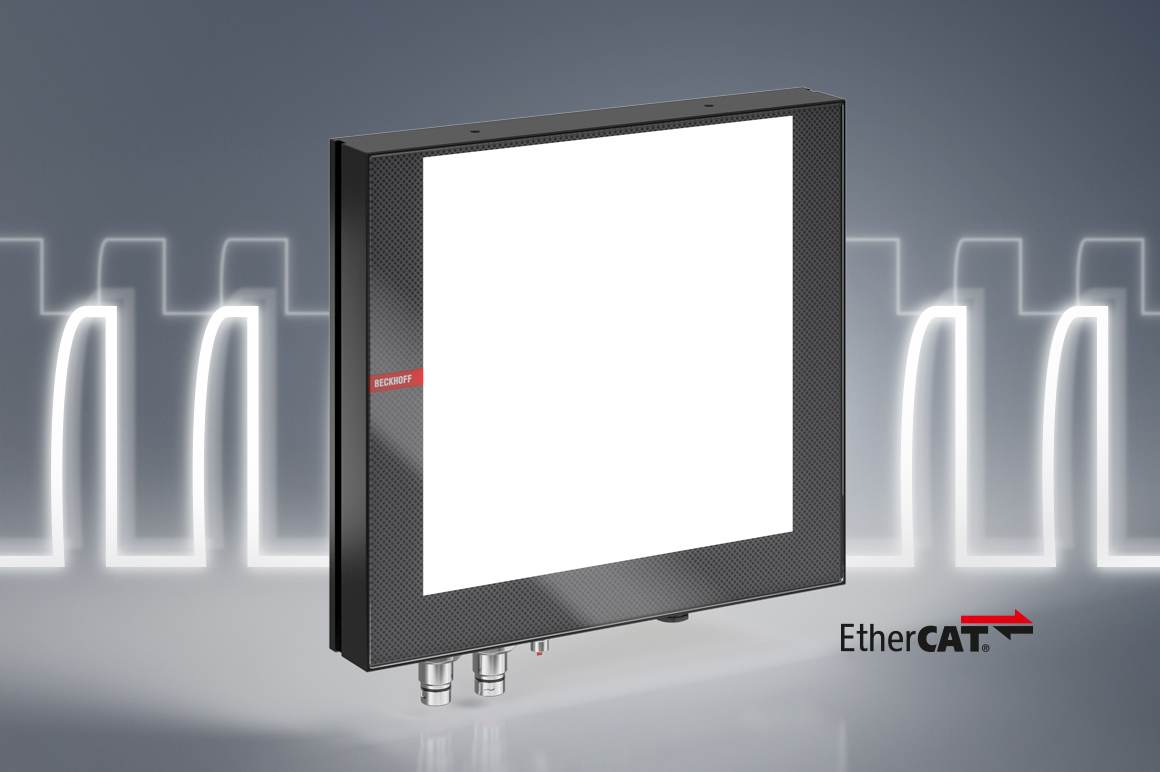

VIP2000 | Panel illumination

Multicolor LED panels are especially optimized for backlight applications.

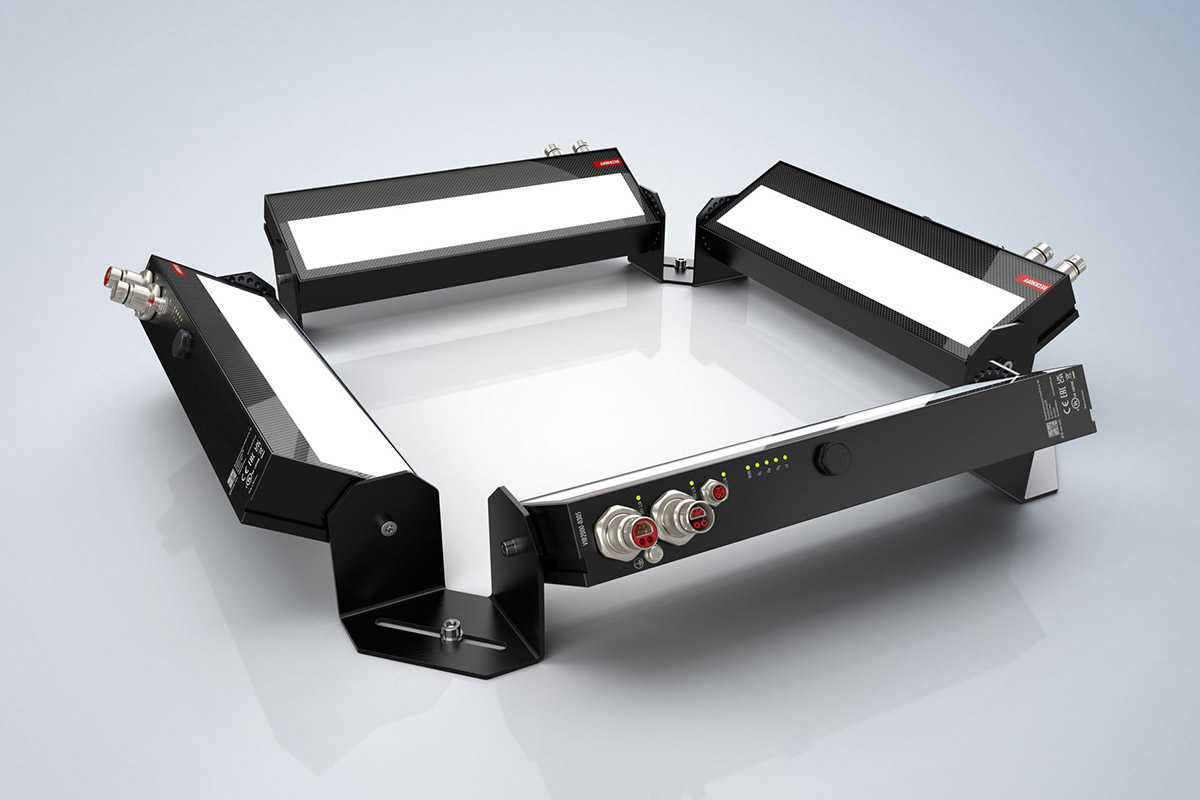

VIR2000 | Ring illumination

The multicolor LED ring is also suitable for dark-field setups.

VIB2000 | Bar light

Universally applicable multicolor LED bar light with homogeneous illumination for backlight applications.

The perfect lighting for every application

The multicolor LED illumination in three designs – area, ring, and bar light – produces constant illumination conditions for consistently high-quality images. This provides an indispensable basis for precise evaluations when processing images. The illumination creates the best possible contrast between the inspection feature and its surroundings – even in spectrally adjustable pulse mode.

The light color of a illumination assembly can be set on a project-specific basis in terms of color and brightness. Mixing the individual color channels makes it possible to produce spectrally complete white light. The direct integration of the power electronics into the illumination assembly achieves a high level of brightness, which is essential for reliable freezing of highly dynamic movements. Full integration into EtherCAT allows users to make individual settings in terms of light color, brightness, and triggering for each individual test object.

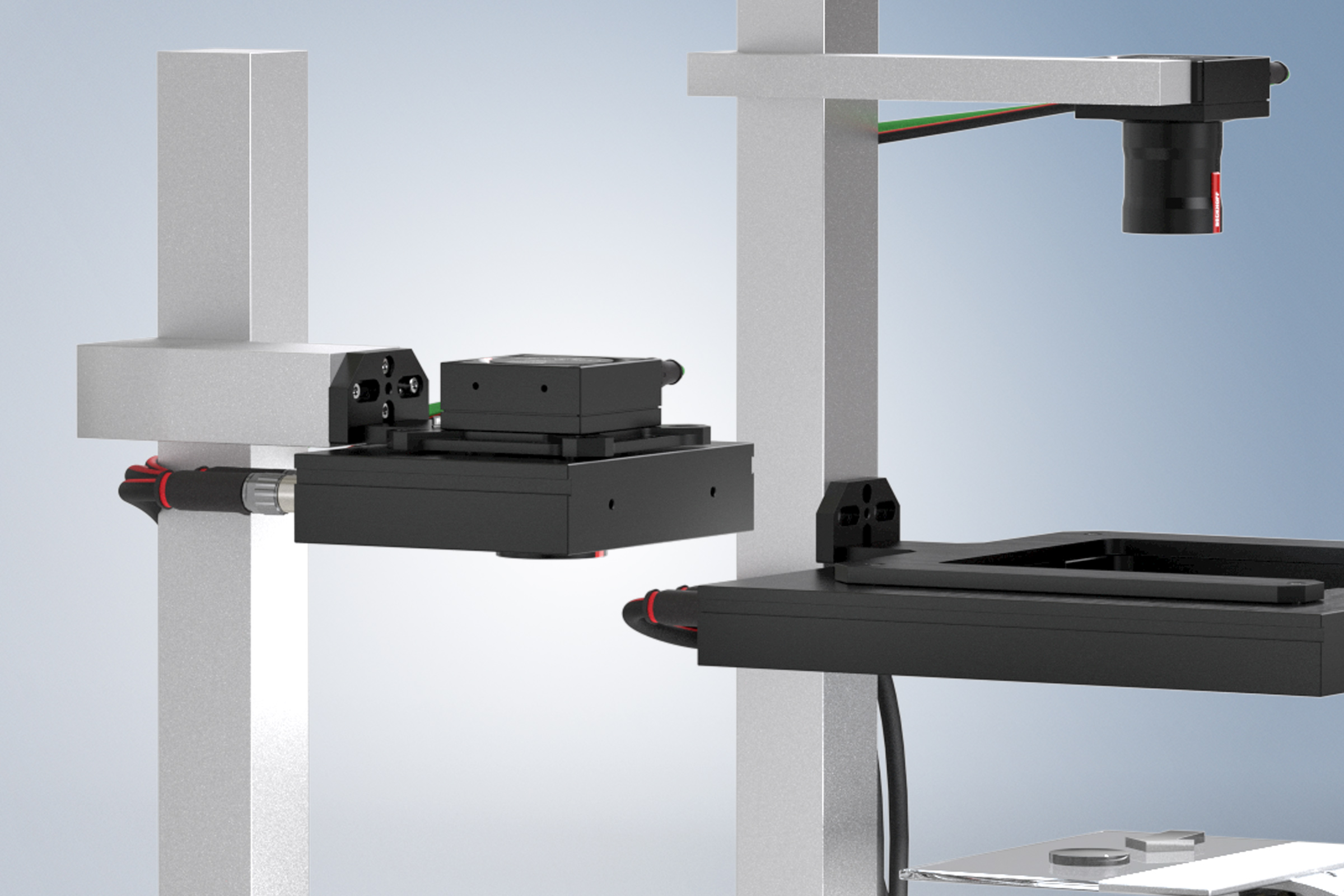

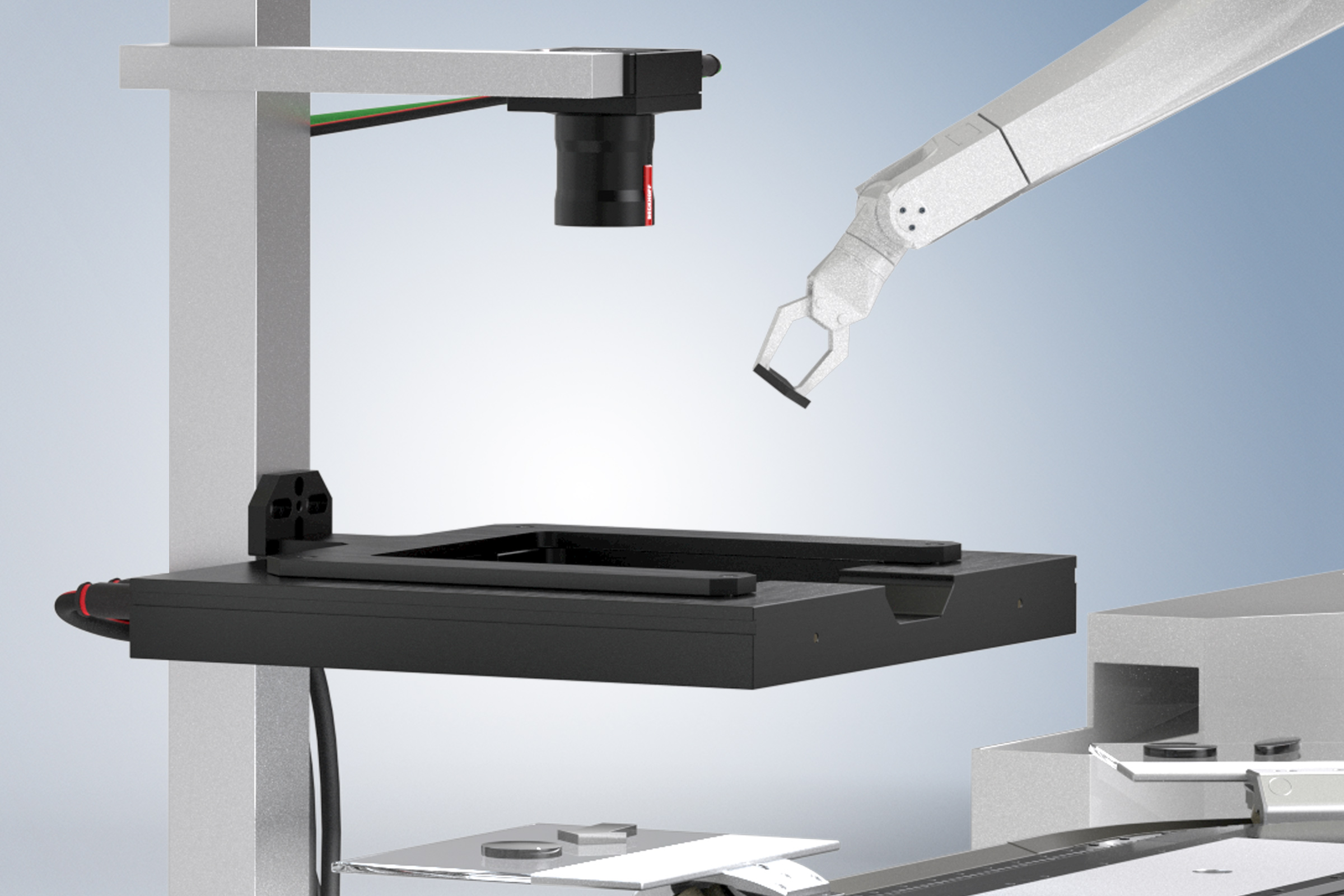

Light is the deciding factor in industrial image processing

When it comes to image processing, it is not the test object or measurement object itself that is recorded by the camera and evaluated by the software, but rather its photometric image. Reliably freezing fast-moving objects requires excellent coordination of the illumination and camera shutters, as well as optimal illumination at the right time with the appropriate brightness.

EtherCAT supports network-wide highly accurate time synchronization of all devices

Due to the synchronization capability of the EtherCAT devices via distributed clocks, pulse operation is easy to implement, since no external trigger loop is necessary for the camera or illumination. EtherCAT has been integrated into TwinCAT, which means that the pulse times of the illumination can be synchronized to the camera and to all other EtherCAT devices in the network without additional hardware and software interfaces.

The appropriately equipped devices support the high-precision time synchronization of all inputs and outputs, typically with time uncertainties of well below 1 μs. This applies both relatively – in relation to the devices in a network – and absolutely to a higher-level global reference time. Highly accurate time synchronization is crucial for efficient flash operation and for complex scenarios with multiple illumination sources and cameras. It allows complete synchronization of the automation elements with the vision elements, which makes the system or machine extremely homogeneous and eliminates system boundaries.

Optimal image results through synchronization with distributed clocks

- from the camera shutter

- from the illumination shutter

- from the pulse intensity

- from the spectral adjustment of the light

Further advantages

- storage of image data with reliably traceable time stamps

- synchronization of the vision system with all other automation elements

- shorter cycle times and improved product quality

- transparent communication and complete parameterization on a fieldbus basis

Advantages at a glance

Illumination precisely synchronized with distributed clocks

With responsive power electronics, the illumination time is synchronized to the image acquisition and to all EtherCAT-based machine processes with outstanding precision.

- real-time applications for optimized manufacturing processes

- integration into the control environment – i.e., in real time

- shutter and flash timing implemented in the standard automation application

- storage of image data with reliably traceable time stamps

- simplified system integration, commissioning, and support

High-precision control and efficient electronics minimize energy requirements

- EtherCAT-controlled flash operation reduces power supply and cooling effort

- the energy consumption of the illumination decreases

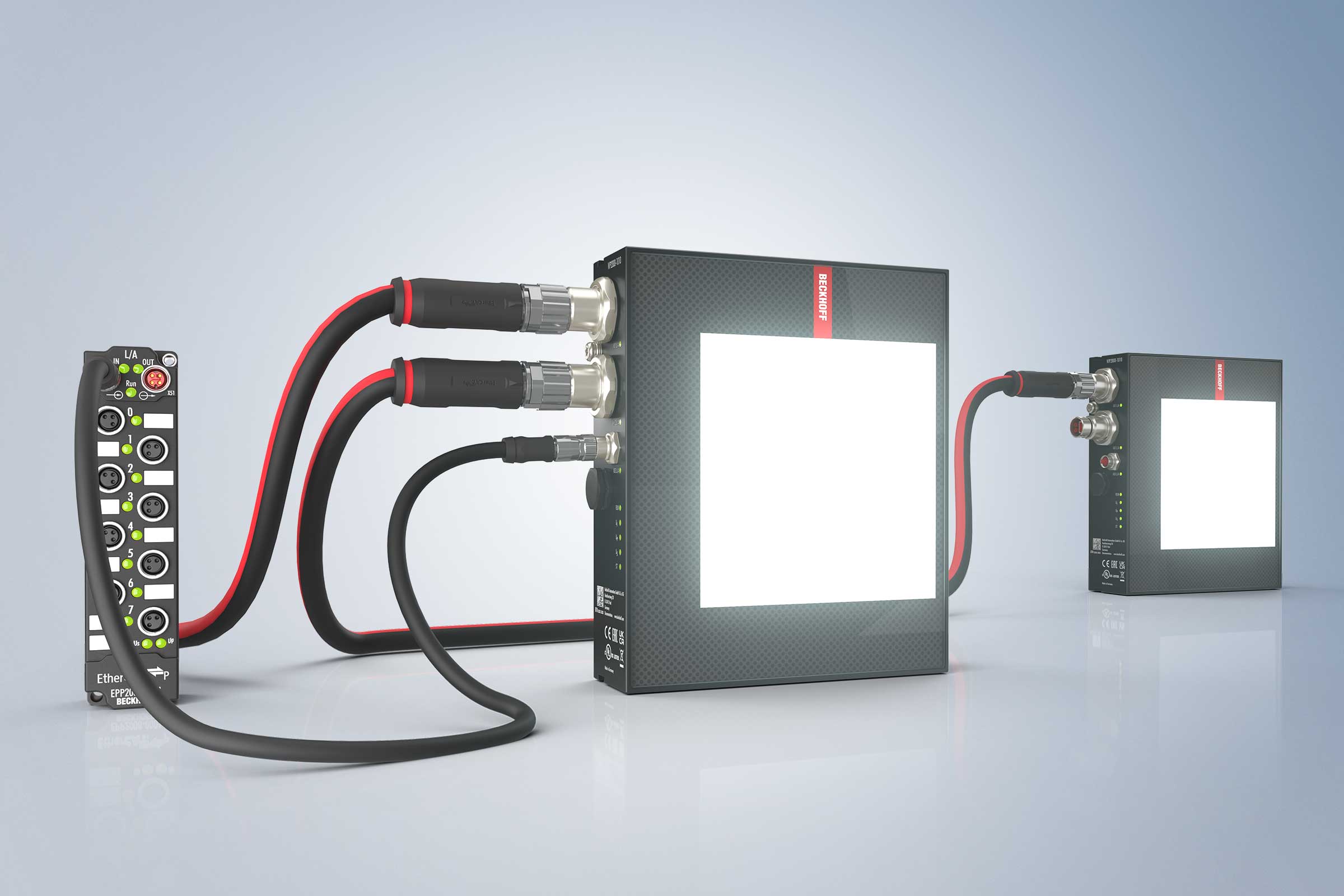

EtherCAT P reduces the wiring work

- connection via B12 EtherCAT P connector

- power supply and synchronization combined in a single cable

- additional pins: power reserve for demanding lighting applications

- straightforward integration

- simple implementation of sophisticated lighting situations through One Cable Technology and daisy chaining

- cost savings afforded by additional M8 EtherCAT P output: further devices such as cameras can be connected directly

- simplified commissioning and straightforward diagnostics

Ability to adjust the image contrast during runtime for maximum flexibility

Multicolor LED illumination can be adjusted individually for each object as follows:

- three selectable channels (blue, green, orange) in the visible spectral range serve to optimize image contrast

- a mixture of these three visible channels produces white light

- IR850 offers an excellent light source to suppress visible features such as multiple print colors.

Generation of the light colors

- with regard to the best possible temperature stability for complete coverage of the visible spectrum via blue LED semiconductors

- the green and red-orange spectral range of the visible spectrum is converted via phosphors for this purpose

- increased efficiency at high temperatures: high light output available in applications with high ambient temperature

Straightforward access to flash mode

In flash or pulse mode, extremely high brightness levels can be achieved while maintaining a low heat load. Power consumption is reduced compared to constant illumination. Depending on the angle of view, flash mode offers a whole host of advantages as a result of the shortened duty cycle and the increased light intensity.

- extremely high pulse power facilitates reliable freezing of movements

- shortening of cycle times due to shorter lighting duration

- simultaneously reduced sensitivity to ambient light

- energy-saving while also extending the LED service life

Range of applications, extending to demanding industrial environments

Advantages of the robust housing

- attractive lighting housing made of anodized aluminum

- IP65/67 water and dust protection

- highly visible status LEDs for visualization of operating states

- thermally hardened and anti-reflective glass for high mechanical and chemical resistance while cleaning and handling

- anti-shatter film available on request for glass surfaces

Advantages of the wide temperature spectrum

- greater flexibility with opportunity for new applications

- extended application possibilities even in demanding environments

- simplified warehousing and purchasing

- reduced costs

Advantages of in-house development and production

- long-term availability of developed types of housing and technology is assured

- best possible vision solution in terms of technology and quality with consistently high level of functionality

- robust product design of the components

- long-term partnership with leading technology and component suppliers

Side connectors: low installation depth when mounted in the optical axis

- large mounting surfaces ensure optimum heat dissipation in the application

- grounding and EMC concepts are easy to implement due to the dedicated ground connection

- the EtherCAT P connection facilitates daisy chaining

- flexible fixing options for the lighting housing

- 4 x M5 embedded threads for rear wall mounting on the back

- 2 x M5 threads on the side

- mounting groove for front mounting with groove nuts